3 T/H Organic Fertilizer Plant

With the growing global demand for organic fertilizers, there is a need for efficient organic fertilizer manufacturing equipment. Indeed, our company’s 3 t/h organic fertilizer plant plan has been highly consulted by overseas customers. Moreover, those looking to produce 30 tons of organic fertilizer daily for organic waste management seek equipment from composting to packing. So, it is an ideal cost-effective solution for small scale organic fertilizer producers or farms with an annual capacity of up to 10,000 tons.

With the growing global demand for organic fertilizers, there is a need for efficient organic fertilizer manufacturing equipment. Indeed, our company’s 3 t/h organic fertilizer plant plan has been highly consulted by overseas customers. Moreover, those looking to produce 30 tons of organic fertilizer daily for organic waste management seek equipment from composting to packing. So, it is an ideal cost-effective solution for small scale organic fertilizer producers or farms with an annual capacity of up to 10,000 tons.

What Equipment Can You Buy for 3 TPH Organic Fertilizer Manufacturing Project?

Setting up a 3 t/h organic fertilizer manufacturing factory requires various reliable equipment. Above all, you can choose to produce powdered or granular organic fertilizers separately, or both of them simultaneously. Thus, you need a compost turner for waste fermentation and a crusher for organic material preparation. Additionally, you need to purchase a mixer, granulators, dryer, screening machine, packaging machine, and conveyors for streamlined operations. Whatever, our plant provides customized solutions for making high-quality organic fertilizer.

3 TPH Organic Fertilizer Powder Equipment List

| Image | Device Name | Feature | Specifications | Quantity |

|

SXLDF-3000 Crawler Type Compost Turner |

It is the most economical compost machine for saving land construction for ground pile organic fertilizer fermentation. |

|

1 Set |

|

SXFM-2030 Loader Type Feeder |

It transports fine organic compost with a size less than 5 mm. | Power: 4 kw | 1 Set |

|

SXSF-60 Semi-wet Material Crusher |

It can handle materials with up to 70% moisture content like animal manure, mud, straw, etc. |

|

1 Set |

|

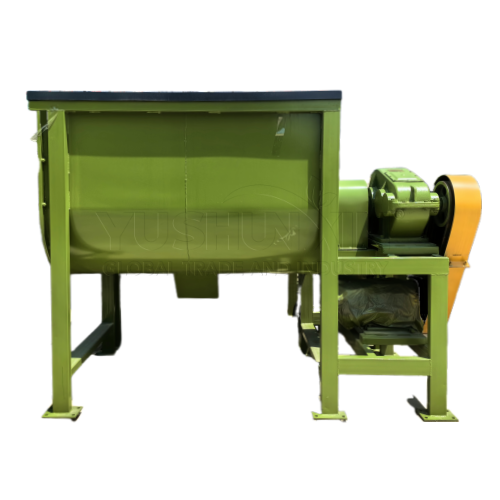

SXWJ-7015 Horizontal Mixer |

This fertilizer blender can achieve fast and soft mixing uniform effect. |

|

1 Set |

|

SXGS-1030 Powder Screening Machine |

It ensures the finished organic fertilizer powder with a size of <50 mesh. |

|

1 Set |

|

1.2*1.2m Finished Product Hopper | Temporarily powdered organic fertilizer storage. | 1 Set | |

|

Single-bucket Powder Packing Scale | It is suitable for packaging small output of powdered organic fertilizers and sealing them. | 1 Set | |

|

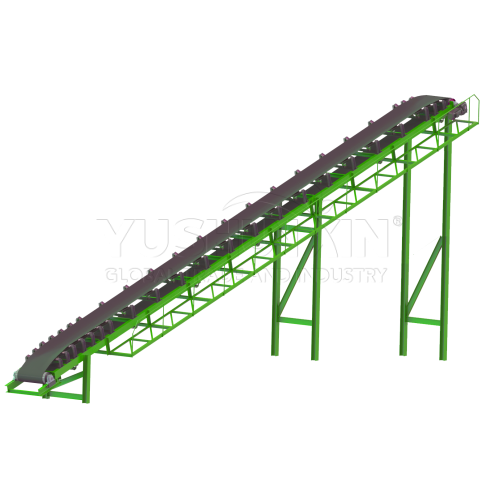

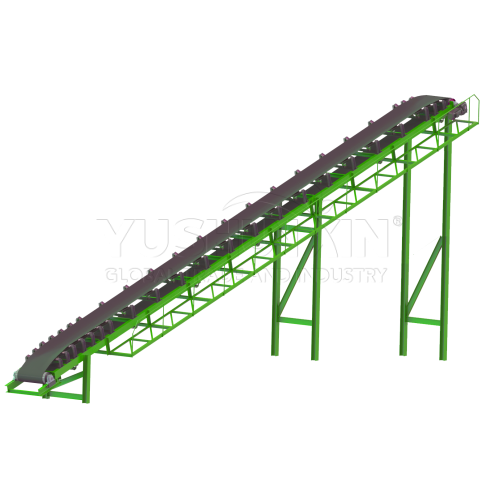

B500 6-8m Belt Conveyor |

To connect every organic fertilizer powder production process. | 6-8 Sets |

Equipment List of 3 T/H Organic Fertilizer Granulation Plan

| Image | Device Name | Feature | Specifications | Quantity |

|

SXCF-4000 Groove Type Compost Turner |

This composter can make organic fertilizer efficient aerobic fermentation, needing 2-3 fermentation groove construction. |

|

1 Set |

|

SXFM-2030 Loader Type Feeder |

It transports fine organic compost. | Power: 4 kw | 1 Set |

|

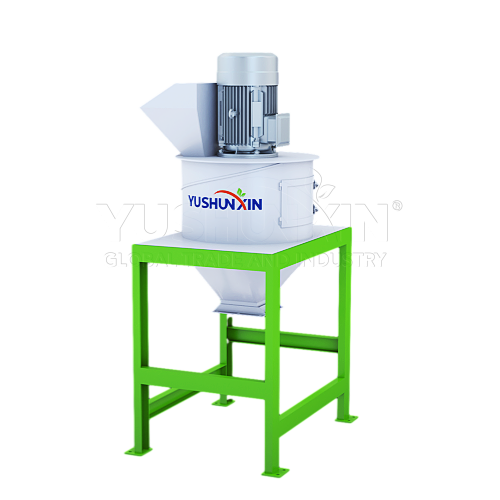

SXFLF-600 Vertical Crusher |

Especially for high moisture organic waste crushing, it’s not easy to block. |

|

1 Set |

|

SXGS-1240 Powder Screening Machine |

It ensure the finished organic fertilizer powder with the size of <50 mesh. |

|

1 Set |

|

SXSJ-0830 Double Shafts Horizontal Mixer |

To ensure continuous mixing of organic waste. |

|

1 Set |

|

SXJZ-1000 New Type Granulator |

Firstly, you can choose this one. The round organic fertilizer granulation rate is up to 95%. |

|

1 Set |

|

SXPM-400 Flat Die Granulator |

Moreover, if you want to make columnar organic fertilizer particles, you can choose this flat die mill. |

|

4 Sets |

|

SXHG-1515 Rotary Dryer & Hot Air Furnace |

This dryer has stable operation and low energy during the 3 tph organic fertilizer pellet drying process. |

|

1 Set |

|

SXLQ-1212 Rotary Cooler |

The cooling machine has simple operation and good stability. |

|

|

|

8C Air Fan | To induce air for dryer and cooler. | 2 Sets | |

|

1200 Cyclone Dust Collector | They collect heavy dust during drying and cooling. | 2 Sets | |

|

SXGS-1240 Granule Screener |

It ensure the uniform finished organic fertilizer pellets size. |

|

1 Set |

|

SXLTF-600 Chain Crusher |

For crushing of return material in 3 t/h organic fertilizer pellet making production. |

|

1 Set |

|

Single-bucket Granule Packing Scale | Suitable for bagging granular organic fertilizers and sewing. | 1 Set | |

|

B500 5-12m Belt Conveyor |

To connect every organic fertilizer granule production processes. | 10-12 Sets |

What Equipment Do You Need to Produce 3 T/H Organic Fertilizer Powder & Pellets?

If you need an organic fertilizer production proposal that can make both 3 tons of powder and granules per hour, we can certainly customize a dual-purpose organic fertilizer manufacturing line for you. Obviously, its equipment configuration is based on the former 3 t/h organic fertilizer granulation line. That is to say, besides the equipment in the graular organic fertilizer making process flow of feeding, crushing, screening, mixing, granulating, drying, cooling, dust removal, screening, and packaging, we will add some additional equipment that you may need.

If you need an organic fertilizer manufacturing plan that can make both 3 tons of powder and granules per hour, we can certainly customize a dual-purpose organic fertilizer manufacturing line for you. Obviously, its equipment configuration is based on the former 3 t/h organic fertilizer granulation line. That is to say, besides the equipment in the graular organic fertilizer making process flow of feeding, crushing, screening, mixing, granulating, drying, cooling, dust removal, screening, and packaging, we will add some additional equipment that you may need.

When planning a 3 t/h organic fertilizer manufacturing project, you can produce powdered or granular organic fertilizers, or both. Thus, you need key organic fertilizer equipment such as compost turners and crushers for waste fermentation and material preparation. Additionally, you require mixers, granulators, dryers, screening machines, packaging machines, and conveyors for efficient operations. If you decide to make both powder and granular organic fertilizers efficiently in one organic fertilizer production line, you may need extra equipment like batching machine and coating machine. Consequently, our plant provides customizable solutions to supply all the necessary equipment for producing high-quality organic fertilizers.

When planning a 3 t/h organic fertilizer manufacturing project, you can produce powdered or granular organic fertilizers, or both. Thus, you need key organic fertilizer equipment such as compost turners and crushers for waste fermentation and material preparation. Additionally, you require mixers, granulators, dryers, screening machines, packaging machines, and conveyors for efficient operations. If you decide to make both powder and granular organic fertilizers efficiently in one organic fertilizer production line, you may need extra equipment like batching machine and coating machine. Consequently, our plant provides customizable solutions to supply all the necessary equipment for producing high-quality organic fertilizers.

Get Free Quote Now!