8 Steps on How to Make The Best Compost

8 Steps on How to Make The Best Compost

The composting process is the most important method for converting organic waste into organic fertilizer. Therefore, the control of the composting process is crucial as it directly affects the nutrient composition of the fertilizer and the absorption and utilization of plants. Here are 8 steps on how to make the best compost!

Call Us For Free Quote:

Step 1: Collection of Organic Waste for Composting

The selection of raw materials for composting is the primary step in enhancing fertilizer quality. Appropriate raw materials should have a high organic matter content, enough nutrients such as nitrogen, phosphate, and potassium, and a lower salt content. Thus, the amount and percentage of these raw ingredients must be chosen depending on unique requirements. Meanwhile, while choosing composting materials, consider the nutritional and chemical content of various materials, as well as aspects such as humidity and density.

Which Materials Can Apply The Composting Process?

There are three rough categories of the selection of raw materials for making compost as follows.

The First Kind Substances

Don’t Decompose Easily- Kitchen Garbage: This includes leftover food, fruit peels, vegetable waste, etc. Why these materials can serve as one of the main raw materials for composting? Because they are rich in organic matter.

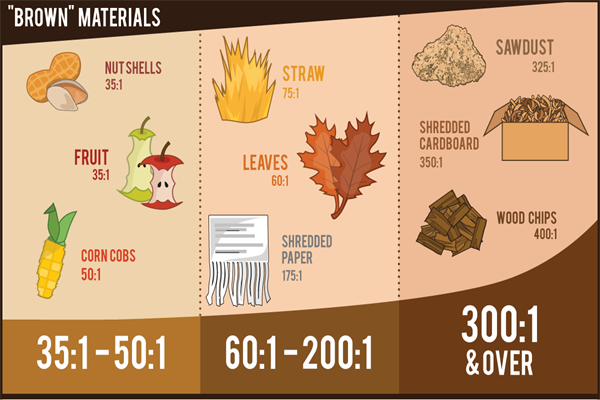

- Crop Residues: The residues of various crops such as straw, weeds, fallen leaves, and vines contain a large amount of cellulose, which can serve as the carbon source and provide microbial energy in compost.

The Second Substances

Promoting DecompositionGenerally speaking, these substances usually contain more hydrogen and are rich in decomposition bacteria, such as human & animal manure or urine, sewage, silkworm excrement, plant ash, lime, etc. In addition, some industrial organic waste can be of use for composting, such as distiller’s grains, pulp waste, etc. The organic matter in these materials can serve as the nutritional source for microorganisms.

The Third Substances

With Strong AbsorptionTo prevent and reduce the volatilization of ammonia, you can add a small amount of peat, clay, as well as superphosphate or phosphate rock powder during the composting process. Hence, it can also improve the fertilizer efficiency of composting.

Note:

- You ought to pay attention to taboos, for instance, plants with herbicides and insecticides cannot be of application in the composting process.

- In addition, it is also important to avoid using materials containing heavy metals and harmful chemicals for negative impacts on the plants.

Step 2: Control of Compost Temperature

Temperature has a significant impact on microbial activity and the decomposition of organic matter during the composting process. For one thing, high temperature composting (over 60℃) can speed up the breakdown of organic waste and enhance composting efficiency. However, excessive temperatures can lead to the loss of certain nutrients.

For another thing, composting at moderate temperatures (40-60℃) and low temperatures (≤40℃) can limit the generation of some hazardous compounds, while the composting duration will be longer. As a result, during this process, you should adjust the composting temperature based on the current circumstances.

How to Effectively Control The Composting Temperature?Several Types of Compost Machines for Your Choice!

Fertilizer plants cannot control the compost temperature directly, but it may be of indirectly regulation by the compost machines. Our equipment can manage the temperature of compost by adjusting the turning speed and frequency.

Here, we will briefly introduce our product series for giving you space to select.

Step 3: Regulation of Compost Moisture

Composting humidity is another major element influencing composting quality. Excessive humidity can cause poor aeration of compost and hinder microbial development, whilst insufficient moisture can delay the pace of organic matter’s decomposition. In general, the moisture of materials should be in the range of 50%-70%.

How to Control Moisture in The Composting Process?

Screw Press Dewatering Machine

During the process of the pre-treatment, laying piles or first turning composts, the water of raw materials should be sufficient as far as possible. Particularly, if the moisture of raw materials are poor, you should supply the upper materials more water than the lower. On the contrary, if the water are beyond 60%, we recommend to buy our screw press dewatering machine for dehydration in advance.

Self-propelled composter

There are two methods to control the moisture content during this process.

- Firstly, you can install water pipes on the wall of the fermentation grooves to spray for increasing water content.

- Secondly, we can customize sprinklers on our compost turners according to customers’ requirements.

By this way, you can do compost work and supply water simultaneously. Besides, the moisture in the compost is also uniform.

When the temperature of the material stabilizes below 40℃, we suggest that there is no need to add water when flipping the piles, otherwise it will affect the post fermentation effect.

Step 4: Aeration Improvement of The Compost

Good ventilation can promote the respiration of microorganisms and the decomposition rate of organic matter during the composting process. Thus, you can increase the aeration of compost by flipping the piles or adding breathable materials such as straw.

Step 5: Ingredients Mixture for Better Fermentation Effect

In the composting process, the mixing of different raw materials can promote the decomposition of organic matter and the interaction of nutrients. Hence, you need to note the following points when mixing materials:

Firstly, you should dispose raw materials in advance (such as crushing, screening, etc.) to facilitate the mixing and composting process.

Our compost grinders are of wide use in bio-organic fertilizer fermentation and composting. For example, we have a semi-wet material crusher specifically designed for high humidity materials such as feces, and another straw crusher for wood flour. And, they are both available in stock.

Secondly, you should carried out reasonable mixing according to the nature and proportion of raw materials to ensure the quality and effect of compost.

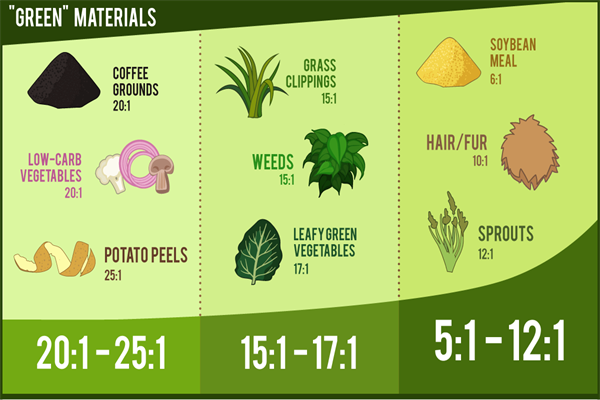

- Under normal circumstances, the C/N ratio should be of regulation between 20:1-30:1. If the C/N ratio is too low, you can add ammonia fertilizer (e.g. urea); If the C/N ratio is too high, you can add cellulose, etc.

Finally, you need to turn the compost material regularly to maintain a good mixing condition.

Step 6: Regular Turning of The Compost

Step 7: Microbial Addition in The Compost

Adding microorganisms is an effective method to improve composting efficiency and quality. Some special microorganisms like Actinomycetes can accelerate organic substances’ decomposition into nutrients, thereby improving the nutritional value of the compost.

How to Control Moisture in The Composting Process?

Step 8: Odour Prevention During The Compost Production Process

The odour has a negative impact on not only the surrounding environmental hygiene, but also agricultural productivity and plant development.

The following are some approaches for odor prevention:

- 1

To begin, choosing suitable raw materialscan limit the production of odorous compounds.

- 2

You should reasonably manage humidityand temperature of the compost to avoid the odorous volatilization.

- 3

To absorb or breakdown odorous compounds, certain adsorbents (e.g. activated carbon, zeolite, etc.) or deodorants (e.g. biological deodorants, etc.) can be of application.

- 4

Finally, to guarantee the sanitation of the environment, it is vital to build a proper composting management system and to swiftly clean and dispose odorous materials.

In short, these 8 steps on how to make the best compost can effectively optimize the composting process and improve the quality of fertilizer. In actual operation, you can make specific selection and application according to the actual situation and demand. Shunxin adheres to the credibility-oriented, excellent quality, favorable price, warmly welcome friends of the service to inquire.

Get Free Quote Now!