ASK & WE ANSWER

frequently asked questions

Get Free Quote Now!

Frequently Asked Questions

We’ve put together some commonly asked questions to give you more information about fertilizr production equipment we offer.

If you have a question that you can’t find the answer, please use the contact page!

How to Disposal Cow Manure When the UK Government Bans Dehydration?

Recently, we, have been receiving many inquiries from our clients in the UK. Moreover, our customer all have highlighted a pressing issue regarding recent shift in the local agricultural policies. With the UK government introducing a ban on cow manure dehydration, cow farms and agricultural businesses across the country face new challenge. Consequently, many clients are seeking our guidance and expertise to develop new plans for handling cow manure to produce organic fertilizer.

What Is The UK’s Current Agricultural Policy for Cow Manure Management?

in fact, the government has recently implemented a policy that bans the dehydration of cow manure in UK. This policy aims to protect river quality by reducing the risk of wastewater pollution in rivers and streams from agricultural practices. The ban on manure dehydration means farmers can no longer use this method to reduce moisture content in cow manure. Instead, they must explore alternative cow manure management techniques that comply with environmental regulations. As a result, many farms and fertilizer plants are urgently seeking alternative production proposals to manage cow dung effectively and sustainably.

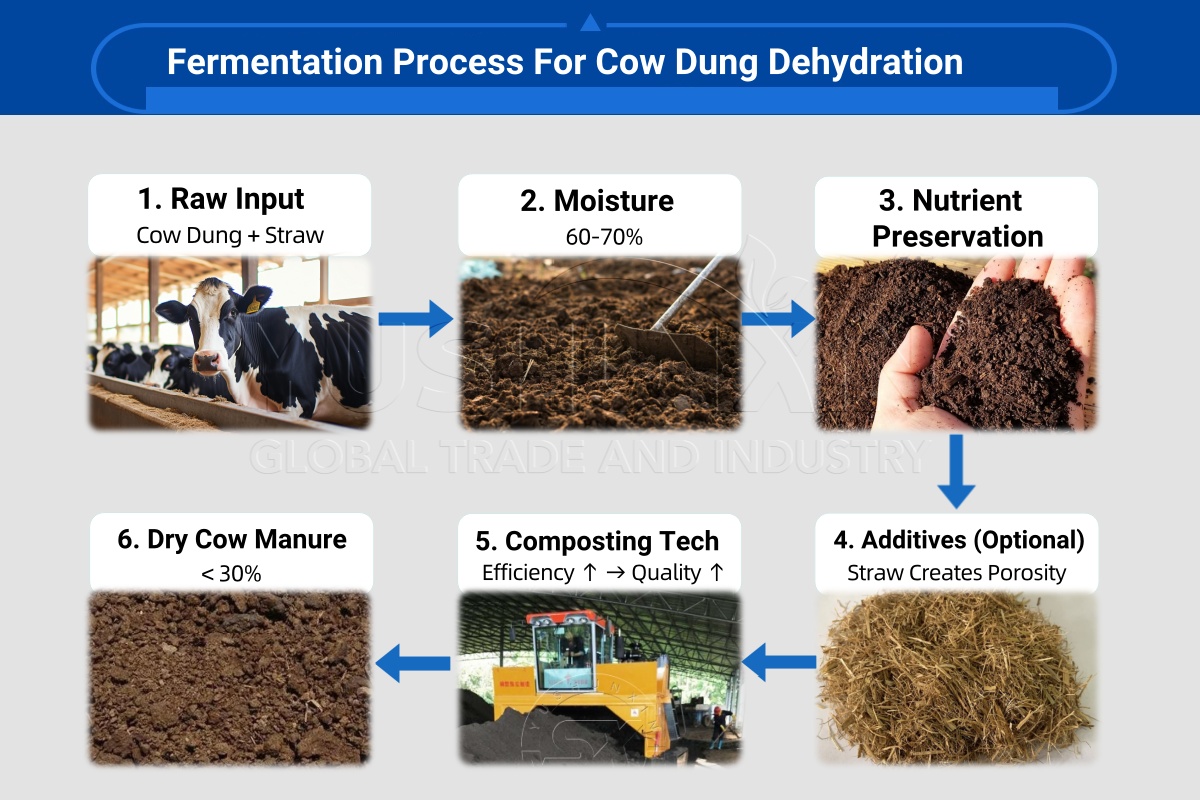

Fermentation As The Second Solution for Cow Manure Disposal

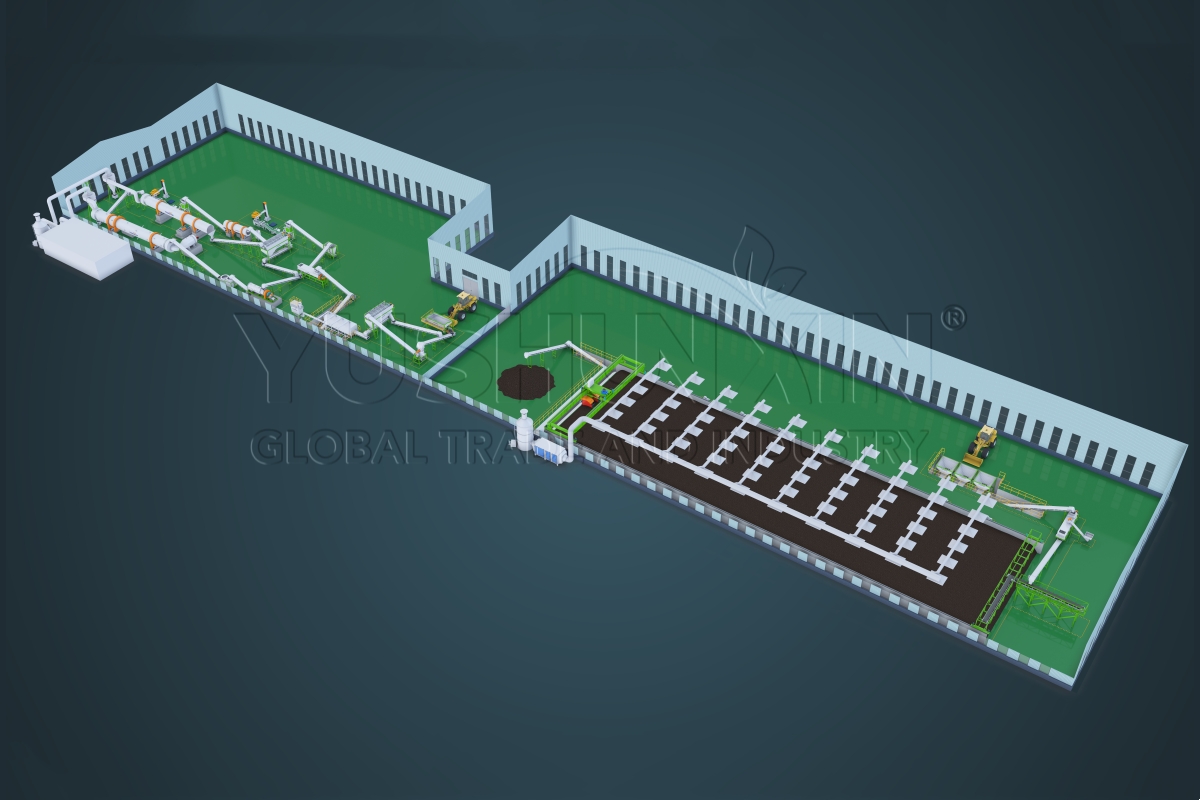

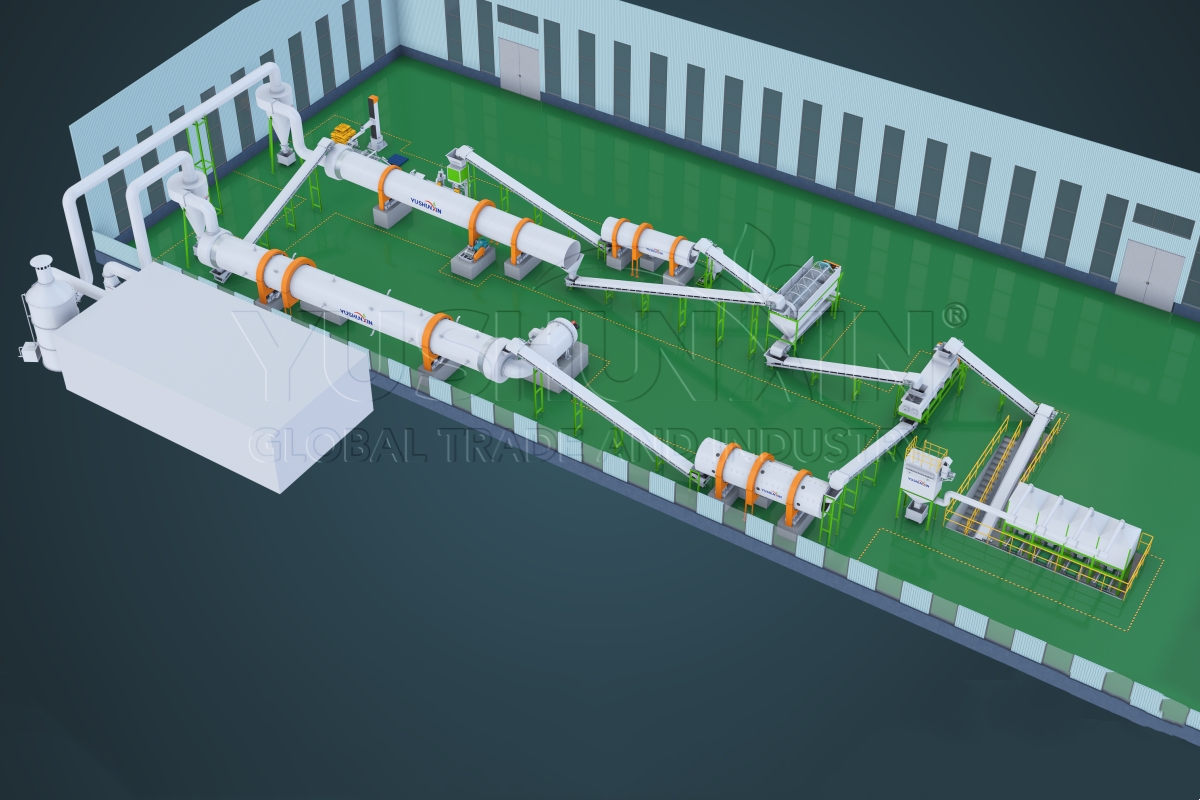

In response, we recommend composting cow dung with straw using advanced fermentation equipment to reduce water content. Because, this process not only promotes the natural evaporation of water but also maintains the nutrient value of organic matter. The effectiveness of aerobic composting lies in its ability to break down organic material efficiently. Besides, straw acts as a bulking agent, creating air channels and facilitating microbial decomposition. Additionally, you can mix ingredients like hay or plant residues into the cow manure composting process to make nutrient-rich organic fertilizer. If you use our specialized compost turners and fermentation machines, it enhances the efficiency and quality of this cow dung dehydration process.

What Equipment Is Suitable for Cow Manure Fermentation In UK?

When dealing with cow manure fermentation, selecting the right composting equipment is crucial. Considering the high moisture content and poor aeration of cow dung, static composting can lead to incomplete fermentation and unpleasant odors. Therefore, we recommend the following composting machines to enhance the cow dung fermentation process and produce high-quality organic fertilizer in UK.

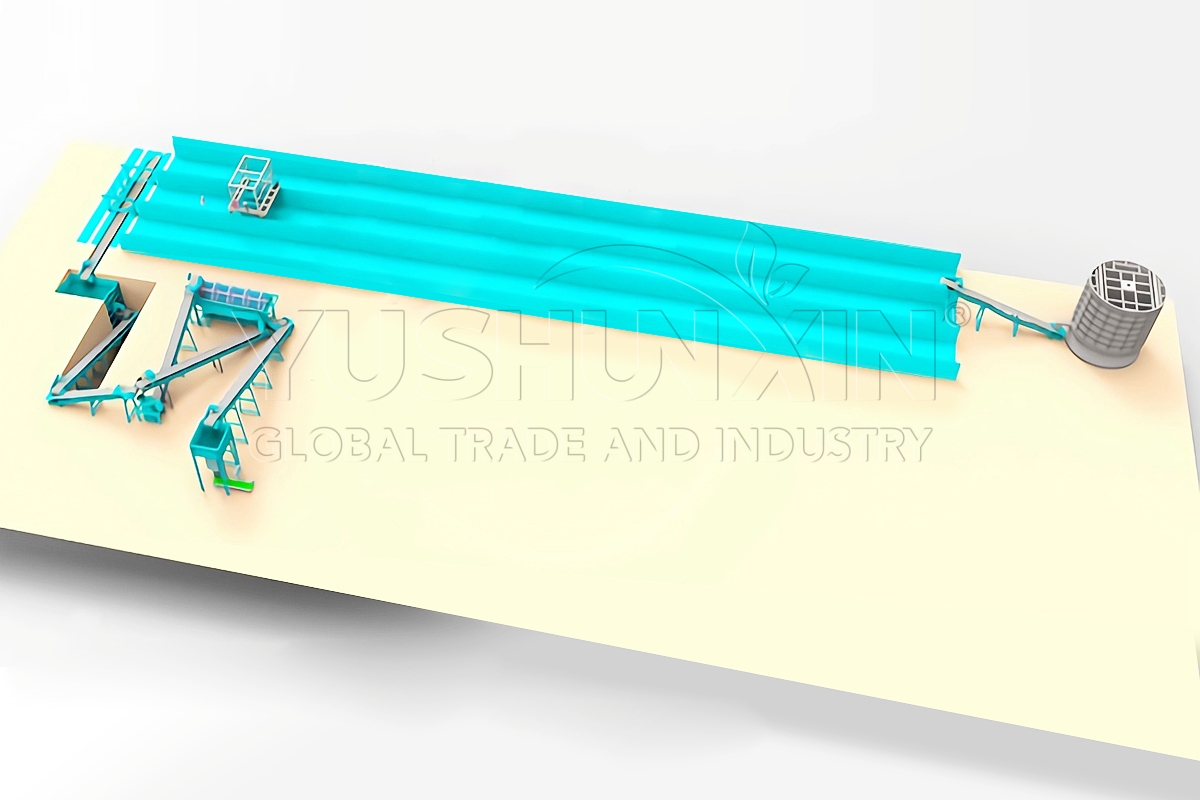

Top Sale of Cow Dung Groove Type Compost Turner

Firstly, groove composting equipment is ideal for medium to large-scale farms or fertilizer manufacturers handling cow manure with a turning width of 2,500-5,000 mm and a turning depth of 800 mm. Additionally, cow manure has a moisture content of about 60-70% and is rich in organic matter. Because the trench system supports higher stacking and larger processing capacity, meeting the temperature and aeration conditions required for effective cow manure fermentation. Also, the groove structure effectively retains heat and moisture, promoting rapid microbial fermentation and resulting in high-quality compost. Mechanical turning reduces labor costs, and regular turning promotes uniform fermentation and cooling. Besides, we can customize groove type composter scale based on production needs, making it suitable for continuous organic fertilizer manufacturing process from cow dung.

Economical Compost Machine for Cow Dung Disposal

Crawler type compost machine is suitable for small to medium-scale cow manure compost operations. It has 2400-3000 mm turning width, 600-1500 mm turning depth, 85-156 horsepower, 500-1500 m³/h capacity. In fact, this machine is flexible and mobile, making it ideal for open sites or smaller composting volumes. Also, it’s cost-effective and practical, with the price of 10,000-20,000 USD. However, due to the high moisture content and low fluidity of cow manure, you need to mix with straw or other high-carbon materials to adjust consistency; otherwise, this windrow compost turner may clog.

Fast Cow Manure Fermentation Equipment

Furthermore, you can choose our fermentation tank for efficient cow dung manure treatment. Compared to the former two cow dung compost turners, the fermentation tank greatly reduces composting time. You benefit from a much shorter organic fertilizer manufacturing process from our equipment. It can shorten the entire cow manure composting and deodorization process from the original 10-20 days to 8-10 hours. Moreover, we can customize 5 m³ horizontal and 10 m³ vertical fermentation tanks. These tanks are suitable for organic fertilizer companies with strict environmental requirements. Because they have enclosed fermentation without odors, fast processing speed, and minimal space. However, they have higher investment costs and limited processing capacity per batch, making them less economical for small farms.

More importantly, Yushunxin is honored to offer our customers a diverse range of efficient composting machinery, including rail type compost turners, windrow type compost turner, and fermentation tanks. Additionally, we guarantee each of these machines by our design to handle the cow dung composting procedure efficiently. Moreover, they significantly reduce the moisture content of compost to below 25%, making it easier to store, handle, and distribute.

Who Are Most Affected by This UK’s Agricultural Policy for Cow Manure Treatment?

The UK’s new agricultural policy for cow manure treatment impacts diverse customers across the agricultural sector. Many farmers, who used to depend on cow dung as organic fertilizer, now require advanced manure treatment technology and production lines. For instance, you may need reliable dewatering machines or efficient composting equipment to optimize the cow dung compost preparation procedure. Additionally, agricultural waste management companies and biogas plants increasingly invest in modern organic fertilizer manufacturing machinery to maximize cow manure value. Besides, you may choose to process manure, poultry droppings, and digestive tract contents into high-quality fertilizer or even use poultry manure combustion for power generation. Some farms also seek cow dung dehydration technology to make bedding materials or export composted fertilizer for profit. Therefore, our plant designs and supplies complete cow dung processing solutions, including compost turners, granulators, and dewatering equipment, helping you comply with regulations.

How to Disposal Cow Manure When the UK Government Bans Dehydration?

In summary, our factory supplies you with advanced cow dung manure composting equipment for your organic fertilizer manufacturing needs. Whether you manage a large-scale fertilizer plant or a small organic farm, our complete production line solutions help you achieve efficient, safe, and profitable fertilizer production. We support you with industry-leading equipment, innovative composting techniques, and a professional after-sales maintenance program. Choose Yushunxin for your cow dung dewatering, composting, and organic fertilizer production line to enhance your operation’s success.

In summary, our factory supplies you with advanced cow dung manure composting equipment for your organic fertilizer manufacturing needs. Whether you manage a large-scale fertilizer plant or a small organic farm, our complete production line solutions help you achieve efficient, safe, and profitable fertilizer production. We support you with industry-leading equipment, innovative composting techniques, and a professional after-sales maintenance program. Choose Yushunxin for your cow dung dewatering, composting, and organic fertilizer production line to enhance your operation’s success.

Get Free Quote Now!

How Much Does A 3T/H Organic Fertilizer Factory Cost in Malawi?

Producing high-strength NPK (Nitrogen, Phosphorus, Potassium) fertilizer pellets is crucial for enhancing agricultural productivity. At Yushunxin, a professional fertilizer equipment manufacturer, we specialize in providing advanced solutions for fertilizer production. The NPK fertilizer dry granulation process, particularly using a double roller granulator, is a key method for achieving durable and uniform pellets. In this article, we explore how to produce high-strength NPK pellets by dry granulation technique, focusing on important factors such as moisture control, particle size, auxiliary materials, and equipment optimization.

Why Is Moisture Control Important in NPK Dry Granulation?

In the NPK fertilizer dry granulation process, controlling the moisture content of raw materials is essential. Excessive moisture content, typically above 8%, can lead to machine blockage in the double roller granulator. This issue not only hampers production efficiency but also increases maintenance costs. On the other hand, insufficient moisture content, usually below 4%, may cause the pellets to fracture easily. Therefore, maintaining the moisture content within the ideal range of 4% to 8% is critical for producing high-strength pellets.

68-200 kW Diesel Generators for Electricity Supply to 1-20 T/H Powder Organic Fertilizer Production Line

At Yushunxin, we provide auxiliary equipment that helps in regulating the moisture levels of raw materials. By ensuring optimal moisture content, you can achieve a consistent granulation process and improve the overall quality of the NPK pellets. Moreover, proper moisture control enhances the performance of the double roller extrusion granulator, leading to higher production efficiency.

How Does Particle Size Affect Pellet Quality in Double Roller Granulation?

The uniformity of raw material particle size significantly impacts the quality of the pellets produced by the double roller granulator. Uneven particle sizes can result in inconsistent pellet formation and reduced strength. By performing appropriate sieving, you can ensure that the raw materials have a uniform particle size distribution. This uniformity allows for better compaction during the granulation process.

Adjusting the roller pressure and the gap between the rollers enables the production of pellets with different sizes. For instance, producing 3mm lime fertilizer pellets requires precise control of these parameters. Consistent particle size not only improves pellet strength but also enhances nutrient distribution in the final product. At our company, we emphasize the importance of particle size adjustment in achieving optimal results in the NPK fertilizer dry granulation process.

What Is the Role of Auxiliary Materials in Enhancing Pellet Strength?

Adding auxiliary materials plays a vital role in increasing the strength and stability of NPK pellets. Binding agents like bentonite and natural clay can be incorporated into the raw mix to improve cohesiveness. These materials enhance the hardness of the pellets, making them more resistant to breakage during handling and transportation.

By carefully selecting and adding the appropriate auxiliary materials, you can significantly improve the quality of the pellets produced by the double roller compaction granulator. Our expertise at Yushunxin allows us to advise on the best auxiliary materials for your specific raw materials and production goals. Incorporating these materials not only strengthens the pellets but also ensures consistent performance in the field.

How to Optimize Pressure and Speed in Double Roller Extrusion Granulator?

The pressure and rotational speed of the rollers in the double roller extrusion granulator are crucial parameters that affect pellet quality. Adjusting the pressure influences the compaction degree of the raw materials, which in turn impacts pellet density and strength. Higher pressure generally leads to stronger pellets, but excessive pressure may cause unnecessary wear on the equipment.

Similarly, the roller speed determines the residence time of the material within the granulator and affects the production rate. By optimizing the pressure and speed, you can control the quality and size of the pellets. Our double roller granulators are designed with adjustable settings, allowing you to fine-tune the operation based on the characteristics of your raw materials. This flexibility ensures that you achieve the desired pellet quality while maintaining efficient production rates.

In summary, producing high-strength NPK pellets by dry granulation technique involves careful consideration of several technical factors. Moisture control is essential to prevent machine blockage and pellet fracture. Adjusting particle size through sieving and roller gap settings leads to uniform and high-quality pellets. Incorporating auxiliary materials like bentonite and natural clay enhances pellet strength and stability. Finally, optimizing the pressure and speed of the double roller granulator allows for precise control over pellet properties.

Offering enough power for fertilizer production is a significant concern, especially in regions with unstable electricity supply. By working with Yushunxin, we suggest buy our advanced fertilizer equipment with a diesel generator, it is possible to meet the power demands efficiently. Furthermotr, our company provides not only high-quality fertilizer production equipment but also comprehensive solutions to secure reliable and cost-efficient power supply.

Get Free Quote Now!

How Much Does A 3T/H Organic Fertilizer Factory Cost in Malawi?

Many of our customers in regions like the Middle East and Africa face challenges with electricity supply. Moreover, they often face issues like power shortages, high electricity costs, or unstable supply, particularly for their fertilizer factories in rural or mountainous areas. They hope that, while we provide information on fertilizer production equipment, we also consider energy issues and offer effective solutions. Thus, we, as a professional fertilizer equipment manufacturer, have devised a reasonable solution to address these concerns about both the power needs and the equipment specifications. In fact, by utilizing diesel generators to provide the necessary power for fertilizer production process, and taking advantage of generally low diesel prices, it’s a practical approach.

How Much Power Does Organic Fertilizer Production Require?

Organic fertilizer production lines can vary greatly in power needs depending on their scale. Also, if you want to make powdered organic fertilizers than organic fertilizer pellets, you may need less power requirement. According to 1-20 t/h organic fertilizer manufacturing process, its power is within 30-400 kW. So we offer different diesel generators for you needs. For instance:

68-200 kW Diesel Generators for Electricity Supply to 1-20 T/H Powder Organic Fertilizer Production Line

Typically, the main processes of a powder organic fertilizer production line include fermentation, crushing, screening, mixing, and packaging. Since it’s relatively simple, the power demand is comparatively low. For instance,

A small-scale fertilizer plant producing 1-3 t/h of organic fertilizer powder requires approx. 30-50 kW of power. So you can meet this electricity need by equipping a diesel generator with an output power of 68 kW.

Furthermore, medium-scale organic fertilizer factory producing 5-10 tons/hour powder will require at least 100 kW of power. A diesel engine with an output power of 150 kW is suitable in this case.

Additionally, a large-scale organic fertilizer powder production plan (20 t/h) requires at least 150 kW of power, requiring a diesel generator with 200 kW output.

What Is the Power Demand for 1-20 TPH NPK Fertilizer Granule Production?

Granular organic fertilizer production lines involve additional processes like granulation, drying, and cooling, increasing power demand.

Generally, a 1-5 tons/hour organic fertilizer granulation line requires around 100 kW, with a diesel engine output of 150 kW.

In addition, the 8-10 t/h granular organic fertilizer production proposal requires around 200 kW of power, and a diesel generator with an output power of 300 kW is appropriate.

For large fertilizer manufacturers to produce 15-20 t/h organic fertilizer granules, the total power will range from 300-400 kW. A diesel generator with an output power of 400-500 kW can fulfill this requirement.

What Are The Power Solutions for 5-80 T/H BB Fertilizer Production?

The bulk blend fertilizer plant layout include material feeding system, conveyors, batching and weighing system, mixing system, and packaging system. For one thing, the common bulk mixing fertilizer production line producing 1-15 t/h of bb fertilizer, the power requirement is about 30-100 kW. A generator with a diesel engine output of 50-150 kW can meet these power demands. For the largest bulk blended fertilizer manufacturing process (50-80 t/h), power needs increase to 200-300 kW, requiring a diesel generator with output of 300-400 kW.

What Is The Power Demand for 1-20 TPH NPK Fertilizer Granule Production?

The 1-20 t/h NPK fertilizer factory equipment configurations may include batching machine, crusher, mixer, granulator, dryer, cooler, screening machine, and bagging machine, etc. The complexity and automation level of the compound fertilizer manufacturing process influence the equipment’s power demand. For various NPK fertilizer production capacities:

A small-scale NPK fertilizer production line (1-8 tons/hour) requires about 80-150 kW, with a diesel generator output of 120-200 kW.

A medium-scale compound fertilizer granulation line (10-15 t/h) has a total power of 200-300 kW, necessitating a diesel generator with output powers of 300-400 kW.

Large npk fertilizer factory (25-40 t/h) will need 400-600 kW of power, and we recommend a diesel engine with 500-800 kW output.

Technical Parameters of Diesel Generators for Fertilizer Manufacturing

| Model | Output Power (kw) | Engine Model | Engine Power | Cylinder | Bore/Stroke (mm) | Discharge (L) | Size (L*W*H) | Weight (kg) |

| SXCF-30 | 30 | YT3B2-D | 40 | 3 | 105/120 | 3.3 | 1800*670*1400 | 670 |

| SXCF-50 | 50 | YT4B2Z-D | 65 | 4 | 108/125 | 4.76 | 2000*780*1220 | 1040 |

| SXCF-68 | 68 | TD520GE | 83 | 4 | 108/125 | 4.76 | 2080*680*1450 | 1150 |

| SXCF-80 | 80 | TAD531GE | 100 | 4 | 108/125 | 4.95 | 2150*750*1450 | 1200 |

| SXCF-100 | 100 | LR6A3L-D | 130 | 6 | 108/130 | 6.49 | 2200*750*1450 | 1300 |

| SXCF-120 | 120 | LR6B3L-DA | 160 | 6 | 108/130 | 6.49 | 2400*870*1450 | 1380 |

| SXCF-150 | 150 | LR6M3L-DA | 200 | 6 | 108/130 | 6.87 | 2550*1000*1450 | 1600 |

| SXCF-200 | 200 | TAD733GE | 300 | 6 | 120/135 | 7.15 | 2600*1020*1500 | 1750 |

| SXCF-250 | 250 | TAD734GE | 340 | 6 | 120/135 | 7.15 | 2800*1100*1500 | 1850 |

| SXCF-300 | 300 | TAD941GE | 400 | 6 | 126/150 | 8.82 | 3000*1100*1560 | 1900 |

| SXCF-350 | 350 | TAD1241GE | 470 | 6 | 126/150 | 9.76 | 3050*1120*1560 | 1950 |

| SXCF-400 | 400 | TAD1242GE | 520 | 6 | 126/150 | 12.1 | 3100*1150*1600 | 2100 |

| SXCF-450 | 450 | TAD1641GE | 590 | 6 | 144/165 | 16.12 | 3200*1200*1650 | 2500 |

| SXCF-500 | 500 | TAD1642GE | 650 | 6 | 144/165 | 16.12 | 3300*1250*1700 | 2700 |

How to Optimize Power Consumption for Fertilizer Production?

Fertilizer equipment model differences can affect power demands since different fertilizer machinery manufacturers and models may have varying specifications. When selecting equipment, it is essential to consider specific fertilizer equipment parameters when selecting machinery to ensure power efficiency.

Furthermore, energy consumption optimization is crucial. Our equipment features energy-saving designs. And the actual running power may be lower than the installed power. This can reduce operational costs while maintaining high performance.

Additionally, process configurations, such as the addition of extra steps like pre-treatment or secondary fermentation can impact the overall power requirements. To ensure the stable operation of the organic or compound fertilizer production line, it is necessary to consider the capacity of the power supply lines and reserve a certain margin.

FAQ

How to Get A Good Power Solution from A Fertilizer Equipment Manufacturer?

Consulting the equipment supplier is a vital step. We, at Yushunxin, can offer customizable power solutions based on your specific fertilizer production line and equipment configuration. In fertilizer equipment selection and process design, we consider using high-efficiency, energy-saving fertilizer production machines and technologies to reduce energy consumption. Of course, you can also buy single fertilizer making machinery equipped with a small diesel generator.

Consulting the equipment supplier is a vital step. We, at Yushunxin, can offer customizable power solutions based on your specific fertilizer production line and equipment configuration. In fertilizer equipment selection and process design, we consider using high-efficiency, energy-saving fertilizer production machines and technologies to reduce energy consumption. Of course, you can also buy single fertilizer making machinery equipped with a small diesel generator.

Offering enough power for fertilizer production is a significant concern, especially in regions with unstable electricity supply. By working with Yushunxin, we suggest buy our advanced fertilizer equipment with a diesel generator, it is possible to meet the power demands efficiently. Furthermotr, our company provides not only high-quality fertilizer production equipment but also comprehensive solutions to secure reliable and cost-efficient power supply.

Offering enough power for fertilizer production is a significant concern, especially in regions with unstable electricity supply. By working with Yushunxin, we suggest buy our advanced fertilizer equipment with a diesel generator, it is possible to meet the power demands efficiently. Furthermotr, our company provides not only high-quality fertilizer production equipment but also comprehensive solutions to secure reliable and cost-efficient power supply.

Get Free Quote Now!

How to Compost Chicken Manure in 18 Days?

Recently, our company has received many customers’ inquiries in poultry farms or organic fertilizer plants. They are very concerned about the equipment and process for composting chicken manure. Here, we provide a comprehensive guide on how to compost chicken manure in 18 days, focusing on the necessary equipment, raw materials, and specific steps involved.

Get Free Quote Now!

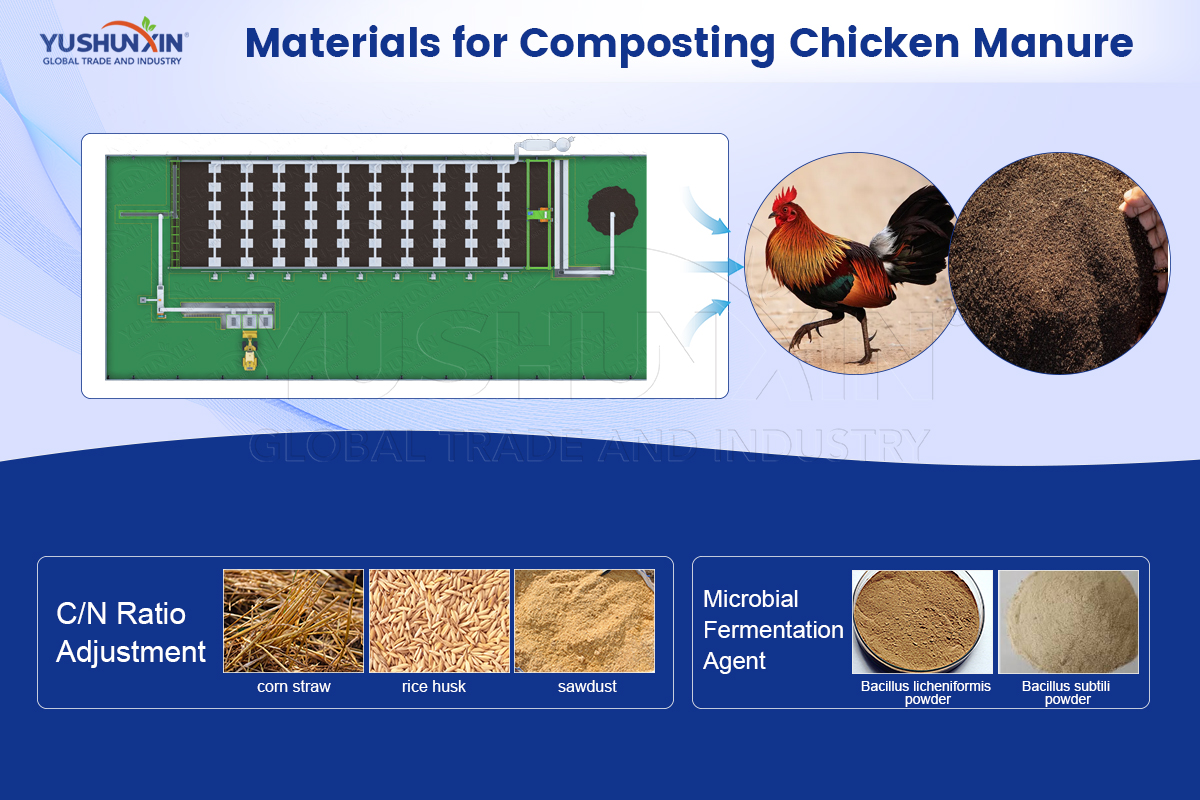

What Raw Materials Are Needed for Chicken Manure Composting?

Indeed, chicken dung is rich in nitrogen and an essential raw material in organic fertilizer production. Composting chicken manure requires a balance of materials to create an optimal environment for decomposition. Typically, maintaining the right C/N ratio in composting process, between 25:1 and 30:1, is crucial for effective composting. In addition, adding carbon sources like rice husk, corn straw, or sawdust helps balance the C/N ratio. Moreover, you can use fermentation bacteria for organic matter quick decomposition. Bacillus subtilis and Bacillus licheniformis are commonly of use to accelerate the composting process.

What Is The Process of Composting Chicken Dung Over 18 Days?

Composting chicken manure involves several steps to ensure the process is efficient and effective. We have summarized the basic day-by-day operation procedure based on the feedback of different customers to their chicken manure composting process.

Day 1-3

Firstly, it’s important to reduce the chicken manure moisture. At the beginning, chicken dung has about 80% water. Thus, a dewatering machine can reduce moisture down to 50-60%. Additionally, you can collect chicken manure and carbon sources to achieve the optimal C/N ratio. You need to add fermentation bacteria to facilitate chicken dung decomposition. Besides, you must pile the materials in a suitable composting area, ensuring good ventilation.

Day 4-7

Secondly, during the chicken manure fermentation process, you must monitor the temperature closely. What’s more, the best fermentation temperature range is 60-70℃. When the temperature naturally exceeds 70℃, you can choose a suitable composting equipment to turn the pile for maintaining aeration and even decomposition.

Day 8-10

Thirdly, you need to continue monitoring the temperature and moisture of compost piles in this stage. The decomposition rate will be high during this phase, and the pile will produce a significant amount of heat. If it’s necessary, you can increase turn frequency of compost piles. Also, if it becomes too dry, you should add water at a certain degree.

Day 11-14

Fourthly, after the 11th day, the temperature of composts may start to stabilize. Certainly, you should keep turning the pile by the compost turner to maintain aeration and moisture at an excellent level. If any foul odors appear, which indicate anaerobic conditions, you must turn the piles more frequently to ensure complete decomposition and uniform mixtures.

Day 15-18

By now, the compost should be mature, with a stable temperature and a crumbly texture. At this time, the moisture content of chicken manure compost should be around 25-30%. Finally, the compost is now ready for the next handling process.

What Equipment Are Essential for Composting Chicken Manure Efficiently?

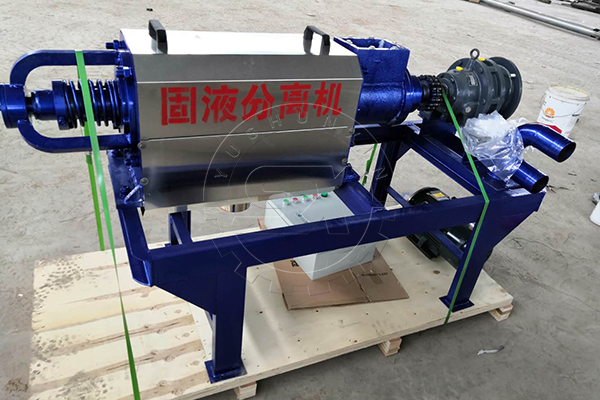

A screw dehydrator is essential for reducing the moisture content in chicken manure before composting. This machine effectively removes excess water, ensuring optimal conditions for the composting process. With durable stainless steel construction, the dewatering machine offers consistent performance and longevity, making it a reliable choice for efficient manure management.

Selecting the right composting machine is crucial for efficient composting. We offer seven types of compost turners. Our composting solutions include groove type turners with customizable depths, wheel and chain plate turners for large-scale operations, and moving and crawler type turners for versatility. We also offer horizontal fermenters for fast processing and vertical fermenters for limited space, though higher cost makes them less ideal.

Furthermore, we can customize an optional water spray system for each compost plans to provide moisture during the composting process. Hence, these machines provide efficient solutions for producing high-quality organic fertilizer powder or granules from chicken manure.

How Do You Know When Chicken Manure Composting Is Complete?

The composting process from chicken manure is complete when appearing several identifiable characteristics:

Temperature Stabilization: The temperature of the pile stabilizes and no longer heats up after turning.

Compost Texture: The chicken dunghas a dark, crumbly texture similar to soil without other recognizable materials.

Smell: There is no offensive odor. Also, it smells like earthy, free from ammonia or foul odors.

Moisture Content: The final product should have a moisture content of 25-30%.

Composting chicken manure in 18 days is available with the right equipment and process management. Our fertilizer production machines offer cost-efficient and effective solutions for every customer. By following these steps and monitoring key factors, you can produce high-quality chicken dung compost efficiently. As a professional fertilizer equipment manufacturer, Yushunxin is committed to providing the best solutions for your composting needs.

Get Free Quote Now!

When you choose our series of granulators, you have the flexibility to select the shape of the granules according to your specific needs. We can produce a variety of shapes including pillow shape, semicircle shape, stick shape, pill shape, walnut shape, flat ball shape, and square bar shape. What’s more, the roller press granulating machine will be your ideal solution. This variety ensures that you can find the perfect match for your project requirements.

Get Free Quote Now!

What Shape of Granules Can You Get From YSX Roller Granulating Machine?

When you choose our series of granulators, you have the flexibility to select the shape of the granules according to your specific needs. We can produce a variety of shapes including pillow shape, semicircle shape, stick shape, pill shape, walnut shape, flat ball shape, and square bar shape. What’s more, the roller press granulating machine will be your ideal solution. This variety ensures that you can find the perfect match for your project requirements.

How Does The Shape Selection Process Work before Granulation?

As a customer, you play a pivotal role in the shape selection process. Initially, you will communicate your preference based on the application for which the granules are intended. Our team from Yushunxin will then guide you through the options, helping you understand the implications of each shape for your project. Once a decision is made, we customize the ball socket on the roller sheet to produce granules in your chosen shape.

Can the Size of the Granules Be Customized?

Yes, alongside the shape, the size of the granules can also be tailored to meet your needs. In addition, we can customize molds for the production of 3-10mm diameter particles, and even larger industrial machine ball shape press granulator can produce pellets in excess of 10mm. Thus, the customization of both aspects is a testament to the flexibility our granulators offer. So, this ensures you receive a product that perfectly aligns with the specifications of your application, enhancing the efficiency and quality of your end products.

What Advantages Do Different Granule Shapes Offer by YSX Granulator?

Different shapes offer unique advantages depending on the application. For example, pillow-shaped granules might be ideal for certain types of fertilizers, providing excellent dispersal properties. Semicircle and stick shapes may be preferred in feed industry for ease of swallowing. Our expertise lies in matching the shape and size of the granules to the intended use, ensuring optimal performance.

How Can We Guarantee Our Granulator Meeting Your Pelletizing Requirements?

To fulfill your specific shape and size requirements, we recommend reaching out to our customer service team. We will engage in a thorough consultation process, understanding your project needs and advising on the best granule shapes and sizes. Afterward, we customize your unique granulating machine to meet these specifications. And before delivery will be a trial run, we can produce the corresponding particle samples and take photos for customer trust.

In conclusion, our series of double roller compact granulators offers unparalleled flexibility in the production of granules, with a wide range of shapes and sizes available to suit your specific needs. By collaborating closely with our team, you can ensure that the granules you make are perfectly adapted to your application, contributing to the success of your projects.

Dry roller press granulator, also known as extrusion granulator, offers several advantages that make it a preferred choice in the fertilizer production industry or other industries. Moreover, as a professional equipment manufacturer in China, Yushunxin ensures that our clients experience the pinnacle of efficiency and quality. Here are some of its key features:

Get Free Quote Now!

1. Energy Saving & Consumption Reduction

One of the major advantages of the dry roller press granulator is its energy-saving and consumption reduction capability. Unlike other methods, this granulation process takes place at room temperature without the need for drying. So you can eliminate the need for drying processes that typically consume substantial amounts of fuel or gas. Then, you benefit from a significant energy savings, aligning with the contemporary need for sustainable production practices.

2. No Need for Another Binder

The dry granulation process featuring the roller press granulator eliminates the need for another binder. Our technology simplifies the granulation process by leveraging the material’s intrinsic inter-molecular forces, negating the necessity for additional binders. This not only streamlines the production process but also reduces the overall cost of production.

3. Cost-Effectiveness & Low Investment

The elimination of the drying process in dry roller press granulation results in several cost-saving benefits. The absence of return material, one-step forming, and low noise make the system simple to operate and maintain, thereby reducing investment costs. This makes the dry roller press granulator a cost-effective choice for fertilizer production, translates into significant savings in terms of both time and money.

3. Flexibility in Raw Material Composition

The extrusion granulation production method offers a wide range of flexibility in terms of raw material composition. It can process different types and concentrations of compound fertilizer. Furthermore, the extrusion granulation process allows for quick product formulation replacement, enabling a set of devices to handle several product formulations within a short period of time.

5. Commitment to Environmental Protection

The dry roller press granulator operates on electricity as its driving force, resulting in no three waste emissions. This aligns with the growing emphasis on environmental protection in enterprises. By employing the granulator, businesses can comply with environmental regulations while maintaining their production efficiency.

6. Long service life

Durability is a hallmark of our granulator, with key components such as the frame constructed from new, corrosion-resistant metals. The bearing frame body is crafted from high-quality, anti-corrosion materials, enhancing stability and extending the service life of the rolling bearings. This guarantees durability and reliability, reducing maintenance costs in the long run.

In conclusion, the dry roller press granulator offers advantages such as energy-saving and consumption reduction, no need for another binder, low cost and investment, flexible composition of raw materials, environmental protection, and long service life. It is a reliable and efficient choice for fertilizer production. And it is a comprehensive solution designed to enhance productivity, sustainability, and efficiency in your production processes.

The engine we use in our fertilizer production equipment, more specifically in crushers, mixers, rotary screening machines, rotary drum dryers and packing machines, are primarily electric. In addition, we’ve found that electric motors tend to offer smoother and more efficient operation, require less maintenance, and are more environmentally friendly compared to diesel engines. Moreover, our composters are available in two drive forms, with three options for electric and two for diesel.

Single Bucket Packing Scale

For example, consider our electric packaging machines. They are designed for swift, precise, and energy-efficient operation. The electric engine ensures consistent performance, reducing the risk of downtime. They also offer quieter operation, improving the working environment by reducing noise pollution.

Crawler Compost Equipment for Sale

On the other hand, we understand that specific scenarios might necessitate the use of a diesel engine. Take our diesel-powered crawler compost turner as an example. This machine is praised for its robustness and high torque, perfect for heavy-duty tasks. Diesel engines are also renowned for their durability and long service life, making them a cost-effective solution in the long run. Moreover, a diesel engine provides more power, which is advantageous in the rough terrains often encountered in agriculture and farming.

However, we understand that some clients might prefer or need a diesel engine. If this is the case for you, we are more than willing to engage in a dialogue and explore possible alternatives to ensure that we meet your specific needs. We are keen on providing equipment that not only meets your functional needs but also aligns with your environmental and sustainability goals. Rest assured, our team of experts will work tirelessly to cater to all your requirements. If you have any more queries or need further customization, our customer service team is always on standby to assist you.

The engine we apply in our fertilizer production equipment is fundamentally an electric motor from a conventional Chinese brand. We’ve chosen this motor based on its commendable performance, undisputed reliability, and the ability to function optimally under diverse operational conditions. In addition, these motors have been tried and tested to ensure they meet stringent quality control standards and deliver consistent results.

We recognize, however, that different clients have different preferences and specific needs. Therefore, we have made a provision to offer a customization option. If you prefer an internationally recognized brand such as Siemens, we can facilitate this change for you. While the change to Siemens or any other global brand of your choice might result in a slight additional cost, we want to assure you that it’s all aimed at ensuring that your equipment aligns perfectly with your individual specifications and standards.

Please note that opting for customization might slightly adjust the delivery schedule of your equipment. Nonetheless, we assure you that the quality, performance, and efficiency of your equipment will in no way be compromised.

Our BB fertilizer mixer is compatible with granule materials, including NPK fertilizers. It processes material quickly, with a turnaround time of 3-5 minutes, and can even produce final material in as little as 40 seconds. With a capacity of 5-10 tons per hour, it meets various production needs. The price is all-inclusive, covering the feed hopper, main cylinder, and essential accessories like the motor and control cabinet. Its efficient discharge system operates by forward rotation for feeding and reverse for discharging.

Our compost crusher is specifically designed for materials that have undergone the fermentation process. For unfermented raw materials, the crusher can still be used directly, provided that the moisture content is between 20-40%. The typical output size from the semi-wet material crusher is about 5-8mm. If a smaller size is required, we recommend using the straw crusher, which includes an internal screen to achieve a finer crush. However, ensure that the moisture content of the materials for the straw crusher does not exceed 15%.

Before granulation, it is essential to ensure that the moisture content of the raw material is around 30%. After granulation, the moisture content of the granules is about 20%. If you require a moisture content below 10%, you can utilize a rotary drum dryer to reduce the moisture content accordingly.

Our organic fertilizer production line equipment is primarily constructed from boiler steel (Q235B), with certain parts crafted from standard carbon steel. For the packing machine specifically, stainless steel is used for the interior. The thickness of the iron components varies by machine and model but is in compliance with national standards. In terms of durability, you can expect a life expectancy of 8 to 10 years from our equipment, although this can vary based on maintenance routines, operating conditions, and general care.

The moving type compost turner is designed with a motor that operates efficiently with water. The machine is equipped with a water tank where water should be added for optimal functionality. It features a fan-based refrigeration system that helps in maintaining the motor’s temperature during operation. When it comes to fuel, the machine uses diesel oil, which is readily available and convenient. For lubrication purposes, normal butter can be applied to ensure smooth operation of the moving parts. In terms of fuel efficiency, the compost turner consumes approximately 8 liters of diesel per hour, making it economically viable for continuous operation during compost turning processes.

Organic fertilizer production from chicken manure attracts many fertilizer plants and farms. Because chicken manure contains abundant organic matter, nitrogen, phosphorus, potassium, and other essential nutrients for crop growth. However, untreated chicken manure damages crops, pollutes soil, and creates odor problems. As a result, you may search for reliable solutions on how to make organic fertilizer by chicken manure. And our company offers complete organic fertilizer equipment to convert chicken manure into valuable compost or granular organic fertilizer. There are 6 steps of chicken manure processing using professional organic fertilizer equipment.

Step 1: How to Efficiently Process And Dehydrate Chicken Manure?

Dewatering is the first procedure in chicken dung organic fertilizer production. And this process reduces moisture, removes impurities, and improves further composting from chicken manure. Our plant recommends using a solid-liquid separator, such as the screw press dewatering machine or inclined type dehydrator. In comparison to inclined dewatering machine, screw pressing dehydrator disposes fresh chicken manure with higher solid content. Indeed, it can squeeze water from fresh chicken dung, reducing moisture from 70% to 30-40%. More importantly, the key part – the screw press, is made of 304 stainless steel, which is corrosion-resistant and has a long service life.

Step 2: What Is the Composting And Fermentation Method for Chicken Manure?

Compost fermentation is a vital step in converting the chicken manure into organic fertilizer. Fertilizer producers must pile up manure in windrows or fermentation grooves. Natural fermentation takes a long time, pollutes the land, and causes odor problems. Thus, it is important to monitor and maintain the right conditions, such as temperature, oxygen levels, and moisture, for microbial activity to break down the organic matter. So we suggest using compost turners because regular turning or stirring of chicken manure will help accelerate decomposition and ensure proper aeration. For instance, our rail type compost turner is suitable for large-scale fertilizer manufacturers to treat chicken manure, operating efficiently and automatically regardless of weather. On the other hand, if you run a small fertilizer plants with limited workshop space, you can choose windrow type compost turner to transform chicken dung into mature compost. Also, we can customize the cab, air conditioner and sprinkling device according to your requirements.

Step 3: Why Is Crushing and Mixing Important in Chicken Manure Fertilizer Production?

After fermentation, you need to crush chicken manure compost into finer particles to enhance nutrient release and mixing uniformity. So we advise compost grinders for this purpose. For example, our new type vertical crusher handles high-moisture chicken dung without blocking. Moreover, the crushing blades adopts wear-resistant alloy for longer working life. Additionally, during this step, you need to blend chicken manure compost with NPK elements, micro-nutrients or additives to improve the overall quality. To ensure uniform chicken manure mixtures, you can use our horizontal blender with even distribution, high efficiency and compact design. Then, they are easy for maintenance and achieve optimal results in your organic fertilizer manufacturing process.

Step 4: How to Granulate Chicken Manure Fertilizer?

Granulation is vital for converting composted chicken manure into uniform pellets or granules. And this step enhances storage, transport, and application for farms and organic fertilizer suppliers. Thus, our company recommends the new type organic fertilizer granulator and flat die granulator for chicken dung processing lines. For one thing, our new type organic fertilizer granulator processes chicken dung with 20-40% moisture. It produces round granules with strong hardness for large-scale organic fertilizer production line. For another thing, the flat die granulator processes chicken manure powder with lower moisture. It produces columnar pellets with stable strength, suitable for dry granulation programs. Besides, the machine has simple design, easy maintenance, and low investment cost. So customers often select it for small to medium chicken manure fertilizer plants. Moreover, both models are made of high-quality materials and can include binding agents for better granulation. And we design more chicken dung granulation solutions according to customer budget and workshop layout.

Step 5: How Should You Dry And Cool Chicken Manure Fertilizer Pellets?

After granulation, chicken manure pellets often retain excess moisture, about 15-20%, especially if produced by wet granulation machines. Besides, our rotary drum dryer efficiently reduce fertilizer granules moisture by hot air. Hence, you can get granular chicken dung fertilizer with the moisture of less than 10%. Next, the drum cooler lower hot pellet temperature to room level, preventing caking and making packaging easier. If you make granules from chicken manure by dry granulation machine — flat die granulator, you needn’t the dry process. In practice, efficient drying and cooling protect fertilizer pellets quality and meet market standards for storage and transport.

Step 6: What Is the Best Way to Pack Chicken Manure Fertilizer for Sale?

The final step in chicken manure organic fertilizer production process is packaging. Our automatic packing machines can weigh, fill, and seal bags of organic fertilizer granules quickly and precisely. To be honest, you can choose single bucket packing scale for the small scale organic fertilizer production from chicken manure. Furthermore, large fertilizer manufacturers can select full automatic packing lines with robotic palletizers. So they achieve the fully-automatic weighing, filling, sewing and transportation of large-scale fertilizer production. In fact, you can reduces labor costs, increases manufacturing capacity, and meet market demand for bulk chicken fertilizer pellet by automation production.

Where to Buy Professional Chicken Manure Organic Fertilizer Production Equipment?

When it comes to purchasing chicken manure organic fertilizer production equipment, there are several options available to you. Here are some resources to help you discover the correct equipment for your needs:

Should You Buy from Local Agricultural Equipment Suppliers?

Firstly, you can buy chicken manure processing equipment from local agricultural equipment suppliers. However, it should be noted that there are incomplete set of equipment for organic fertilizer production and lack of technical support and after-sales services, making it hard to solve equipment problems quickly. Usually, local suppliers act as intermediaries, and they do not engage in equipment manufacturing. As a result, you may not be aware of precise chicken manure production process. And you may not get direct manufacturer prices or detailed technical specifications of organic fertilizer machines.

Why Choose Direct Purchase from An Organic Fertilizer Equipment Manufacturer?

You can cooperate directly with our plant for more reliable service and better pricing. As a professional fertilizer equipment manufacturer, we offer factory-direct prices, technical support, and customization for your unique chicken dung manufacturing process. Also, we design complete chicken manure production lines, including dewatering machines, compost turners, crushers, mixers, granulators, dryers, and packing systems. Then, our experienced team provides installation guidance and after-sales service.

How Do Online Marketplaces Help with Chicken Dung Equipment Selection?

We strongly suggest that you can purchase organic fertilizer manufacturing equipment from the official Alibaba website of organic fertilizer production equipment manufacturer. The website has detailed prices, features, parameters, images, and videos of our products, which can help you quickly understand our equipment. Welcome to contact us for free quotation!

How to Disposal Cow Manure When the UK Government Bans Dehydration?

The use of organic fertilizer equipment streamlines the process and ensures that the end product is safe, effective, and easy to handle. By following these six essential steps of separation, fermentation, crushing and mixing, granulation, drying and packaging, chicken manure becomes a valuable resource for agriculture production. Dear customers, please contact us as soon as possible! Our professional team will be happy to serve you and provide you with the best solution of organic fertilizer production.

The use of organic fertilizer equipment streamlines the process and ensures that the end product is safe, effective, and easy to handle. By following these six essential steps of separation, fermentation, crushing and mixing, granulation, drying and packaging, chicken manure becomes a valuable resource for agriculture production. Dear customers, please contact us as soon as possible! Our professional team will be happy to serve you and provide you with the best solution of organic fertilizer production.