Small Scale Bio-fertilizer Production

In recent years, using a large number of chemical fertilizers and pesticides have exacerbated the soil pollution problem. Improper management will cause the surrounding environment pollution, agricultural products quality degradation, and a serious constraint on the sustainable development of livestock and poultry farming.

If you want to improve the environment for processing fertilizers and application or the quality of agricultural products, the bio-fertilizer production line is undoubtedly one of the best choices for small scale fertilizer factories and farms.

What Types of microbes Are Potential for Bio-fertilizer Production?

It takes a long time to develop and cultivate good strains, and enterprises must face the difficulties of hi-tech precise devices costs, production base building, and human resource investment in the development process. These costs are too expensive to be suitable for small scale fertilizer factories and small scale breeding industries. Hence, we propose that you can purchase strains from relevant institutions or vendors.

Ordinary strains are commonly accessible and affordable. Common strains include bacillus, silicate bacteria, phosphate solubilizing microorganism, mycorrhizal fungi, antibiotic bacteria, etc.

The strains of compound bio-fertilizers are rhizobia, nitrogen-fixing microorganism, photosynthetic bacteria, yeasts, lactic acid bacteria, actinomycetes, etc.

Among them, the most frequently used strain is bacillus in the bio-fertilizer production.

What Are The Appropriate Materials (Carriers) for The Production of Bio-fertilizers?

If you hold a small farm, your ingredients are very accessible. Therefore, you can be self-sufficient while saving money on raw materials. Furthermore, the raw materials are relatively inexpensive to purchase, and the purchasing location is not far away from you plant.

Livestock and poultry manure is the main raw material for producing cheap and high quality bio-fertilizer. This is because it has a high concentration of crude protein, crude fiber, minerals and calcium, phosphorus, potassium, nitrogen and other nutrients.

Auxiliary materials serve as carriers for microbial inoculation, such as cake (e.g. soybean cake, oil-seed meal and groundnut meal), grain residues (e.g. wheat bran, rice husk, straw, corn flour, cassava starch residue, etc.), soil (e.g. compost, ash, grass charcoal, etc.), or adding husk or sawdust to facilitate ventilation for better aerobic fermentation.

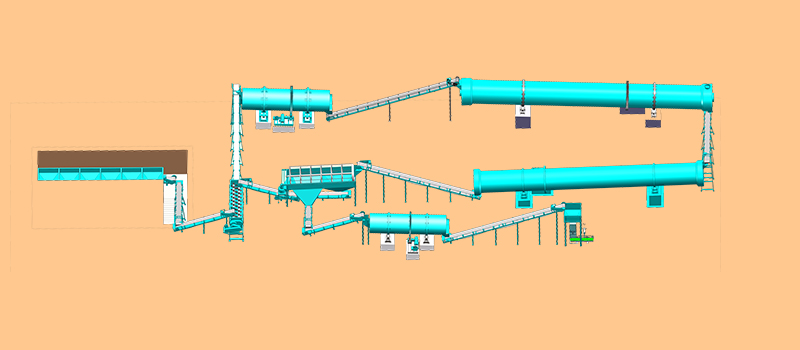

Small Scale Bio-fertilizer Production Process

If there is small scale production, we recommend that you choose the static manufacturing bio-fertilizer process. This method is simple, easy to operate, less investment, and suitable for local production of small-sized fertilizer plant and farm.

Detailed Steps

Appropriate Equipment for Small Scale Bio-fertilizer Production

1. Animal Manure Dewatering Machine

It is a kind of solid-liquid separator, which can handle livestock manure like pig, chicken, cow, and horse dung into liquid or solid organic fertilizer. The former can be directly used for crop to absorb. And the latter not only is convenient for transportation, but also can improve the soil structure and be made into organic compound fertilizer after fermentation.

2. Moving Type Compost Turner

The machine can be used in the open air or in the workshop. It is the most affordable type of compost equipment. It is usually equipped with a canopy, and can also be designed with a cab based on customers’ requirements.

3. Crawler Type Compost Turner

The machine has a compact design, simple operation, and workplace saving. Full hydraulic power design makes basically no mechanical wear and tear, and ensures low warranty rate. The biggest feature of the machine integrates the crushing function of the later fermentation process and improves the efficiency of crushing.

4. Straw Crusher

The straw crusher is mainly used for crushing and processing various crop wastes such as corn stalks, straw, peanut shell, bean stalks and so on with a diameter of less than 5cm. The machine has reliable performance, simple and convenient operation, and covers a small area.

5. Horizontal Mixer for Bio-fertilizer

The machine has good ability of mixing and less residual materials, which is suitable for mixing of compound feed, concentrated feed fertilizers, additives and so on.

Get Free Quote Now!