How Much Does A 3T/H Organic Fertilizer Factory Cost in Malawi?

Many of our customers in regions like the Middle East and Africa face challenges with electricity supply. Moreover, they often face issues like power shortages, high electricity costs, or unstable supply, particularly for their fertilizer factories in rural or mountainous areas. They hope that, while we provide information on fertilizer production equipment, we also consider energy issues and offer effective solutions. Thus, we, as a professional fertilizer equipment manufacturer, have devised a reasonable solution to address these concerns about both the power needs and the equipment specifications. In fact, by utilizing diesel generators to provide the necessary power for fertilizer production process, and taking advantage of generally low diesel prices, it’s a practical approach.

How Much Power Does Organic Fertilizer Production Require?

Organic fertilizer production lines can vary greatly in power needs depending on their scale. Also, if you want to make powdered organic fertilizers than organic fertilizer pellets, you may need less power requirement. According to 1-20 t/h organic fertilizer manufacturing process, its power is within 30-400 kW. So we offer different diesel generators for you needs. For instance:

68-200 kW Diesel Generators for Electricity Supply to 1-20 T/H Powder Organic Fertilizer Production Line

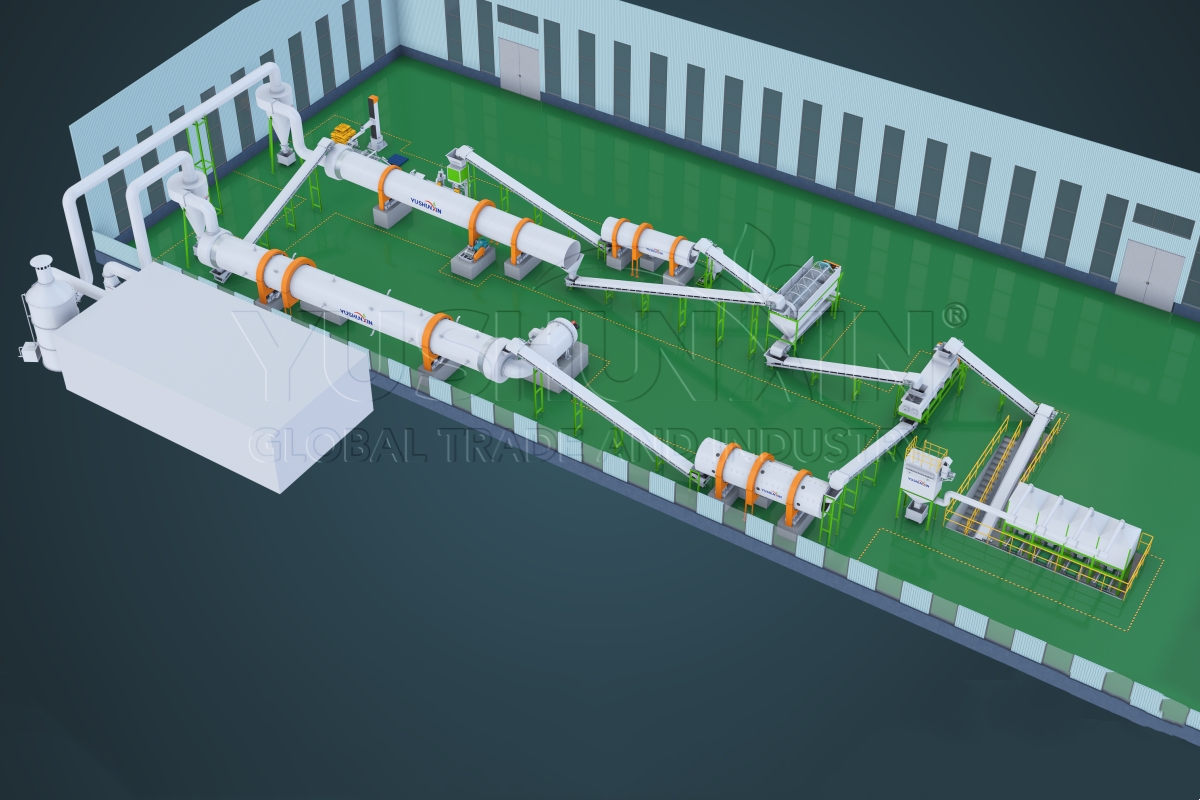

Typically, the main processes of a powder organic fertilizer production line include fermentation, crushing, screening, mixing, and packaging. Since it’s relatively simple, the power demand is comparatively low. For instance,

What Is the Power Demand for 1-20 TPH NPK Fertilizer Granule Production?

What Are The Power Solutions for 5-80 T/H BB Fertilizer Production?

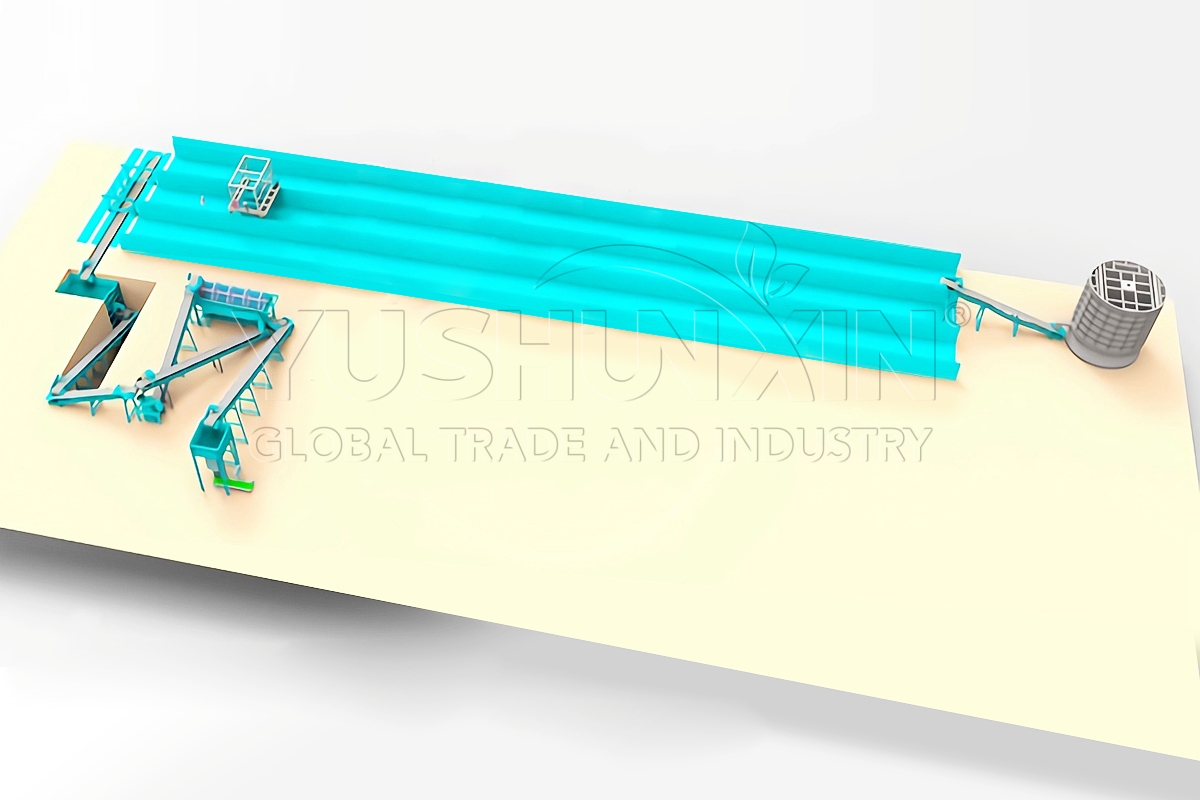

The bulk blend fertilizer plant layout include material feeding system, conveyors, batching and weighing system, mixing system, and packaging system. For one thing, the common bulk mixing fertilizer production line producing 1-15 t/h of bb fertilizer, the power requirement is about 30-100 kW. A generator with a diesel engine output of 50-150 kW can meet these power demands. For the largest bulk blended fertilizer manufacturing process (50-80 t/h), power needs increase to 200-300 kW, requiring a diesel generator with output of 300-400 kW.

What Is The Power Demand for 1-20 TPH NPK Fertilizer Granule Production?

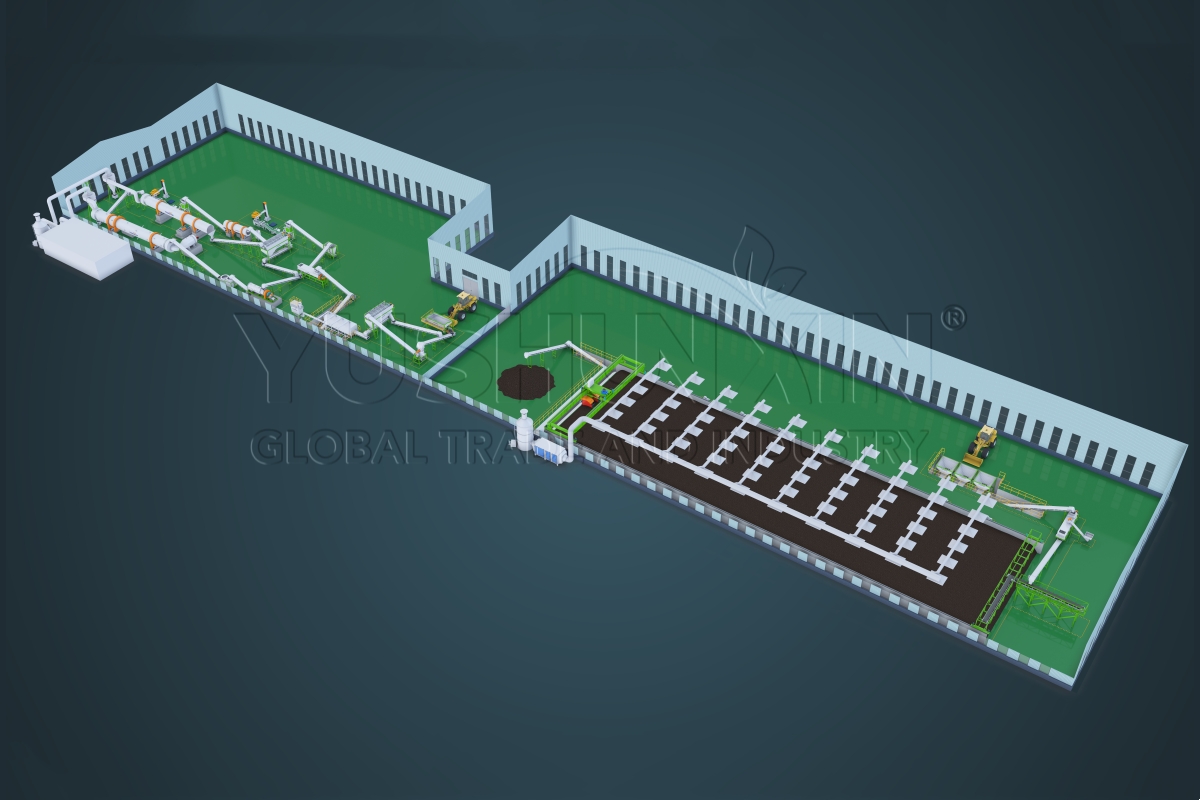

The 1-20 t/h NPK fertilizer factory equipment configurations may include batching machine, crusher, mixer, granulator, dryer, cooler, screening machine, and bagging machine, etc. The complexity and automation level of the compound fertilizer manufacturing process influence the equipment’s power demand. For various NPK fertilizer production capacities:

Technical Parameters of Diesel Generators for Fertilizer Manufacturing

| Model | Output Power (kw) | Engine Model | Engine Power | Cylinder | Bore/Stroke (mm) | Discharge (L) | Size (L*W*H) | Weight (kg) |

| SXCF-30 | 30 | YT3B2-D | 40 | 3 | 105/120 | 3.3 | 1800*670*1400 | 670 |

| SXCF-50 | 50 | YT4B2Z-D | 65 | 4 | 108/125 | 4.76 | 2000*780*1220 | 1040 |

| SXCF-68 | 68 | TD520GE | 83 | 4 | 108/125 | 4.76 | 2080*680*1450 | 1150 |

| SXCF-80 | 80 | TAD531GE | 100 | 4 | 108/125 | 4.95 | 2150*750*1450 | 1200 |

| SXCF-100 | 100 | LR6A3L-D | 130 | 6 | 108/130 | 6.49 | 2200*750*1450 | 1300 |

| SXCF-120 | 120 | LR6B3L-DA | 160 | 6 | 108/130 | 6.49 | 2400*870*1450 | 1380 |

| SXCF-150 | 150 | LR6M3L-DA | 200 | 6 | 108/130 | 6.87 | 2550*1000*1450 | 1600 |

| SXCF-200 | 200 | TAD733GE | 300 | 6 | 120/135 | 7.15 | 2600*1020*1500 | 1750 |

| SXCF-250 | 250 | TAD734GE | 340 | 6 | 120/135 | 7.15 | 2800*1100*1500 | 1850 |

| SXCF-300 | 300 | TAD941GE | 400 | 6 | 126/150 | 8.82 | 3000*1100*1560 | 1900 |

| SXCF-350 | 350 | TAD1241GE | 470 | 6 | 126/150 | 9.76 | 3050*1120*1560 | 1950 |

| SXCF-400 | 400 | TAD1242GE | 520 | 6 | 126/150 | 12.1 | 3100*1150*1600 | 2100 |

| SXCF-450 | 450 | TAD1641GE | 590 | 6 | 144/165 | 16.12 | 3200*1200*1650 | 2500 |

| SXCF-500 | 500 | TAD1642GE | 650 | 6 | 144/165 | 16.12 | 3300*1250*1700 | 2700 |

How to Optimize Power Consumption for Fertilizer Production?

How to Offer Enough Power for Fertilizer Production?

How to Get A Good Power Solution from A Fertilizer Equipment Manufacturer?

Consulting the equipment supplier is a vital step. We, at Yushunxin, can offer customizable power solutions based on your specific fertilizer production line and equipment configuration. In fertilizer equipment selection and process design, we consider using high-efficiency, energy-saving fertilizer production machines and technologies to reduce energy consumption. Of course, you can also buy single fertilizer making machinery equipped with a small diesel generator.

Consulting the equipment supplier is a vital step. We, at Yushunxin, can offer customizable power solutions based on your specific fertilizer production line and equipment configuration. In fertilizer equipment selection and process design, we consider using high-efficiency, energy-saving fertilizer production machines and technologies to reduce energy consumption. Of course, you can also buy single fertilizer making machinery equipped with a small diesel generator.

Offering enough power for fertilizer production is a significant concern, especially in regions with unstable electricity supply. By working with Yushunxin, we suggest buy our advanced fertilizer equipment with a diesel generator, it is possible to meet the power demands efficiently. Furthermotr, our company provides not only high-quality fertilizer production equipment but also comprehensive solutions to secure reliable and cost-efficient power supply.

Offering enough power for fertilizer production is a significant concern, especially in regions with unstable electricity supply. By working with Yushunxin, we suggest buy our advanced fertilizer equipment with a diesel generator, it is possible to meet the power demands efficiently. Furthermotr, our company provides not only high-quality fertilizer production equipment but also comprehensive solutions to secure reliable and cost-efficient power supply.