BB Fertilizer Plant Cost

As a professional fertilizer equipment manufacturer, we believe establishing a BB fertilizer plant is ideal for first-time investors or newcomers to the fertilizer industry. Due to low initial investment, bb fertilizer plant cost for purchasing NPK fertilizer production equipment is between $30,000 and $200,000. Because the bulk blended fertilizer production process is simple – batching, mixing, packing – the required equipment is much less than in organic or compound fertilizer plants. Consequently, you only need smaller factory area, greatly saving on land and construction costs. Furthermore, such a bb fertilizer production line can produce 1-80 t/h of NPK mixing fertilizer. So, building a BB fertilizer plant is a cost-effective way to enter the NPK fertilizer industry.

💰 $30,000-100,000 | ⚖️ 5-80 T/H | 🏠 500-3,000 ㎡

As a professional fertilizer equipment manufacturer, we believe establishing a BB fertilizer plant is ideal for first-time investors or newcomers to the fertilizer industry. Due to low initial investment, bb fertilizer plant cost for purchasing NPK fertilizer production equipment is between $30,000 and $200,000. Because the bulk blended fertilizer production process is simple – batching, mixing, packing – the required equipment is much less than in organic or compound fertilizer plants. Consequently, you only need smaller factory area, greatly saving on land and construction costs. Furthermore, such a bb fertilizer production line can produce 1-80 t/h of NPK mixing fertilizer. So, building a BB fertilizer plant is a cost-effective way to enter the NPK fertilizer industry.

How Much Does A BB Fertilizer Plant Cost for Different Compound Fertilizer Production Scales?

F

or one thing, you can purchase granular NPK fertilizer for BB fertilizer mixing, so you need a common bulk blending fertilizer manufacturing line with batching, mixing and packing. Moreover, we have a quotation of 1-80 t/h NPK fertilizer mixing projects within the budget of 30,000-200,000 USD. For another thing, if you want to start making bb fertilizer granules from powder, you need to add an extra NPK fertilizer granulation line with 1-20 t/h of capacity. Beside, your cost to set up a BB fertilizer factory will increase by $15,000-400,000.

Price Lists of 1-80 T/H BB Fertilizer Production Lines

Our company offers cost-effective and efficient BB fertilizer plant project. After purchasing NPK granules, you can set up bulk blended fertilizer factory with simple equipment configuration. It mainly includes automatic batching machine, rotary drum mixer, and automatic packaging scale, thereby greatly reducing your initial equipment investment. Moreover, the production capacity of the NPK blending fertilizer plant is very strong. It can produce 1-80 t/h of NPK fertilizer granules per hour with flexible proportion. Furthermore, the cost to purchase this bulk mixing fertilizer production line ranges from $30,000 to $200,000.

How Much Does It Cost to Produce BB Fertilizer Granules from NPK Powder?

S

ome experienced customers find that purchasing NPK granules in bulk is too costly. Therefore, they consider producing bulk blended fertilizer granules from NPK powder. We recommend purchasing an additional NPK granulation production line of the same capacity. Also, we suggest the dry granulation process because it eliminates the need for drying, saving equipment costs and factory space.

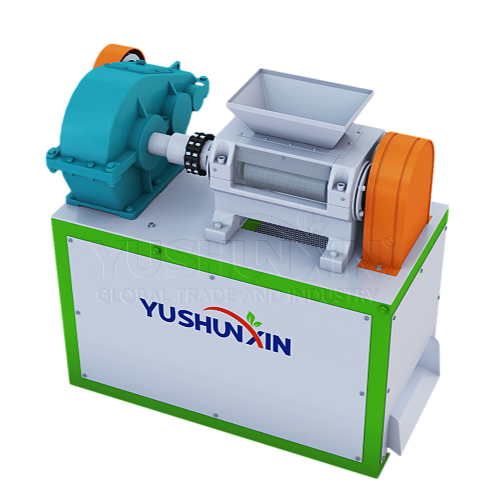

As a result, you may require a double roller granulator for extrusion granulation, which is simple and yields uniform granule size and shape. In addition, you will need to add a chain crusher, horizontal mixer, screening machine, and so on for efficient production. However, the maximum capacity of an NPK fertilizer pellet making system is only 20 t/h. Therefore, customers needing to produce over 20 t/h of BB fertilizer must purchase such two or more granular compound fertilizer production lines. Thus, the total equipment cost for a 1–20 TPH NPK fertilizer blending granulation plant ranges from $45,000 to $600,000.

What Are BB Fertilizer Production Equipment Prices in 1-80 TPH NPK Mixing Fertilizer Plant?

For BB fertilizer plant layout, the mixing equipment is the most crucial component. Generally speaking, if your production demand for bulk blend fertilizer is less than 15 t/h, you can select a BB fertilizer mixer. However, if your production demand exceeds 20 t/h, it is best to choose a continuous drum type BB fertilizer mixer. Besides, you may need other fertilizer machinery.

Which NPK Fertilizer Equipment You Can Choose for BB Fertilizer Production?

List of NPK Mixed Fertilizer Production Solution Equipment Price & Parameters

| 1-15 TPH BB Fertilizer Production Line | |||||

| Machine | Name | Capacity | Power | Quantity | Price |

|

Static Batching Machine | 4.4 kw | 3-4 Bins | $2,000-2,250/bin | |

|

Dynamic Batching Machine | 4.4 kw | 3-4 Bins | $3,600-4,000/bin | |

|

Bucket Conveyor | 1 | $3,000-3,500/set | ||

|

BB Fertilizer Mixer | 1-15 T/H | 5.5 kw | 1 | $3,000-3,600/set |

|

Storage Bin | 1 | $1,500-2,000/set | ||

|

Single-bucket Automatic Packing Machine | 1-2 | $4,000-5,800/set | ||

| 20-80 T/H Bulk Mixing Fertilizer Manufacturing Line | |||||

|

Dynamic Batching Machine | 4.4 kw | 4-6 Bins | Total: $14,400-24,000 | |

|

Drum Type BB Fertilizer Blender | Customized | 1-2 | $4,600-12,000/set | |

|

Disc Feeder | 2-12 T/H | 7.5-15 kw | 1-3 | $2,000-6,500/set |

|

Double-bucket Automatic Bagging Scale | 2-4 | $6,500-8,500/set | ||

|

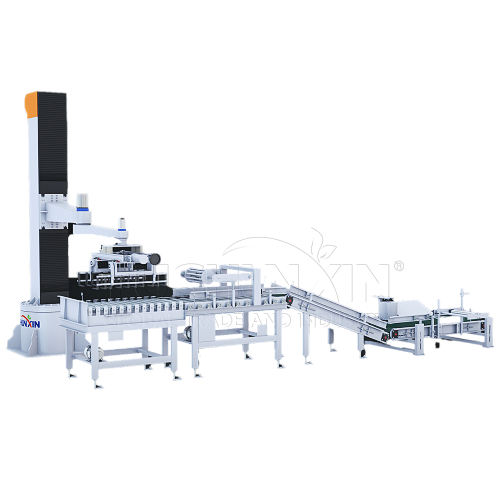

Robot Palletizer | $15,000-20,000/set | |||

| NPK Fertilizer Dry Granulation Production Line | |||||

|

Chain Crusher | 1-15 T/H | 11-37 kw | 1 | $1,500-7,500/set |

|

Horizontal Mixer | 2-15 T/H | 7.5-22 kw | 1 | $2,000-11,000/set |

|

Disc Feeder | 2-12 T/H | 7.5-15 kw | 1-3 | $2,000-6,500/set |

|

Double Roller Extrusion Granulator | 1-2 T/H | 15-22 kw | 1-12 | $2,600-4,600/set |

|

Rotary Screening Machine | 1-20 T/H | 3-11 kw | 2 | $1,350-11,000/set |

|

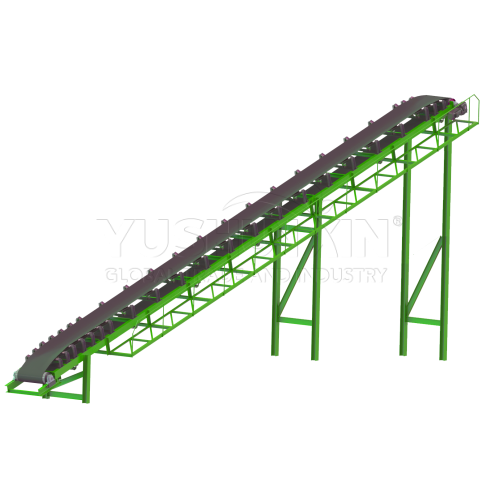

B800 Belt Conveyor | Customized, 6-10m | $2,000-3,800/set | ||

In conclusion, selecting the right equipment for your 1-80 TPH NPK mixing fertilizer plant is essential. Our company, Yushunxin, offers BB fertilizer production equipment tailored to your needs. For capacities under 15 TPH, you can choose our simple production line with a BB fertilizer mixer. However, if your demand exceeds 20 TPH, we recommend our continuous drum type BB mixer and additional machinery. By understanding your requirements, we provide suitable equipment and competitive prices. We are committed to supporting your fertilizer production goals with high-quality solutions.

Land Cost in Setting Up A BB Fertilizer Factory

Building a bulk blend fertilizer factory requires careful consideration of land costs. Land expenses vary widely depending on the region and the scale of operations. Indeed, the entire fertilizer NPK blending plant includes production areas, warehouses, and office areas, etc. Therefore, you must understand these costs to plan your investment effectively.

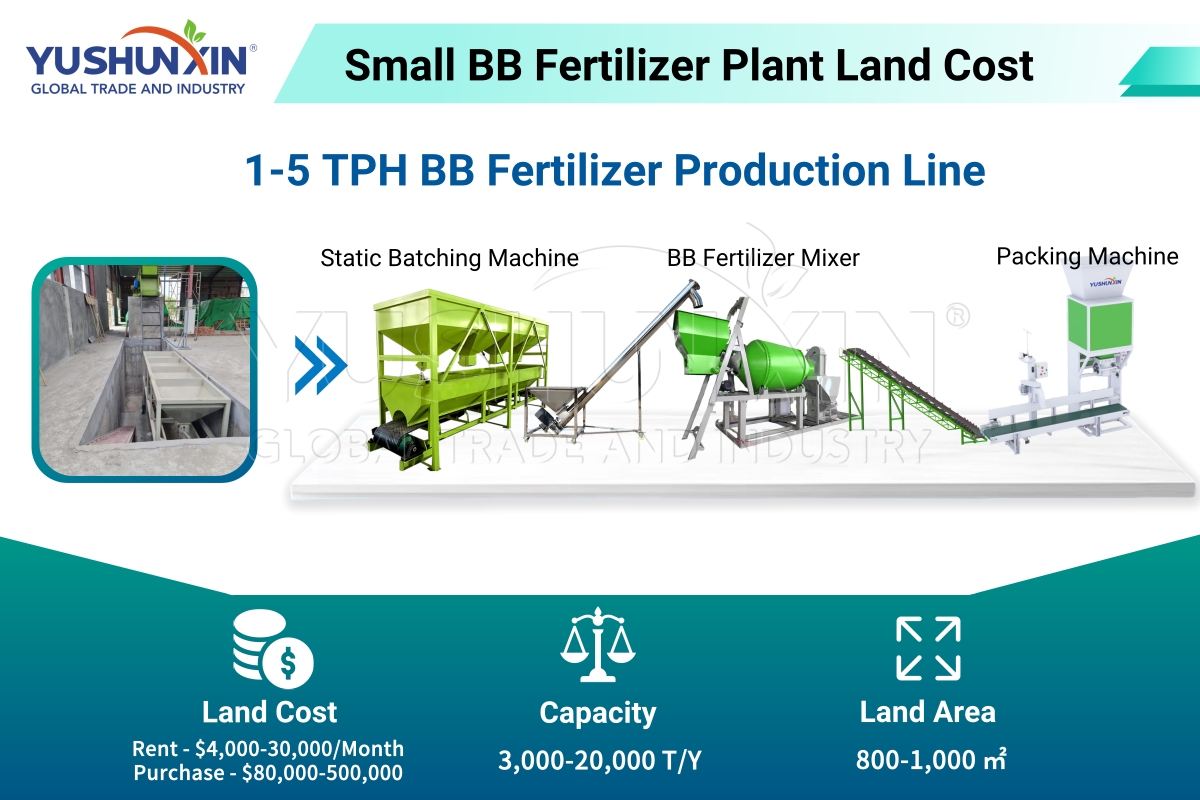

What Is A 3,000-20,000 T/Y BB Fertilizer Plant Land Cost?

If you are a small-scale bulk mixture fertilizer producer with annual production of 3,000-20,000 tons, you need at least 500 square meters for 1-5 tph bb fertilizer production line installation. Moreover, the entire NPK fertilizer plant occupies approx. 800-1,000 square meters. With leasing rates at $5-30/㎡ monthly, your rent ranges from $4,000 to $30,000. Purchasing land at $100-500/㎡ would cost between $80,000 and $500,000. Additionally, if you need to produce NPK granules, the area for bulk mixing fertilizer factory increases to 1,000-1,200㎡, potentially raising rent and purchase costs accordingly.

How Much Land Does 10-20 TPH Bulk Blended Fertilizer Plant Project Cost?

For medium-scale NPK fertilizer producers with an hourly output of 10-20 tons and annual production of 30,000–60,000 tons, you require a fertilizer mixing production line covering 600–800 ㎡. Besides, the total NPK mixed plant area is 1,000–1,400 ㎡. Therefore, your monthly rent of 10-20 t/h bb fertilizer production plan could range from $5,000 to $42,000, while purchasing land might cost between $100,000 and $700,000. If you plan to granulate BB fertilizer from powder, the area requirement increases to 1,500–1,800 ㎡, leading to higher land costs.

Land Cost of 50-80 T/H NPK Fertilizer Blending Production Proposal

If you are running a large-scale NPK fertilizer factory with the capacity of 50-80 t/h. And you will annually make 100,000–300,000 tons NPK mixtures. In addition, you need to leave 1,200–1,600 ㎡ land for installing bulk mixing fertilizer manufacturing line. Also, the entire fertilizer blending factory covers 1,800–2,400 square meters. Consequently, your monthly rent could be between $6,000 and $48,000, and purchasing land might cost from $120,000 to $800,000. Furthermore, if you start with NPK granule production, the bulk blend fertilizer factory’s area expands to 3,000–3,500 ㎡, which increases the land costs even more.

Establishing a 1-80 TPH BB fertilizer factory requires careful planning, and land cost is a key factor. You can contact us, and we will conduct an on-site inspection of your plant configuration. We customize bulk mixing fertilizer plant layout design plans for you and handle installation. Thus, we assist you in optimizing your land costs.

All in all, we believe that establishing a BB fertilizer plant is an ideal way for newcomers to enter the NPK fertilizer industry. Because we offer cost-effective and efficient BB fertilizer plant projects, you can produce high-quality NPK fertilizer with low initial investment. Therefore, you should consider partnering with us to design your BB fertilizer plant. We invite you to contact us for a customized bulk blended fertilizer production system design plan.

Some fertilizer businesses and investors planning to set up a organic fertilizer plant should pay particular attention to understanding the fertilizer production plant cost. Moreover, the expenses involved in establishing such a organic fertilizer factory include land rent, plant construction, fertilizer production equipment, costs of raw and auxiliary materials, labor, energy consumption, return on investment, and more. Depending on the type of raw materials and the desired output, we can provide customized solutions for the production of organic fertilizer powder or granules or liquid fertilizer. All in all, these fertilzizer manufacturing plans cater to clients with equipment budgets ranging from $30,000 to $550,000.

Get Free Quote Now!