BB Fertilizer Production Line

Bulk blending fertilizer (BB fertilizer for short) is a blended compound fertilizer by mixing several single or compound fertilizers in definite proportions. Thus, BB fertilizer production line easily carries out batching, mixing, packing procedures with flexible formula options.

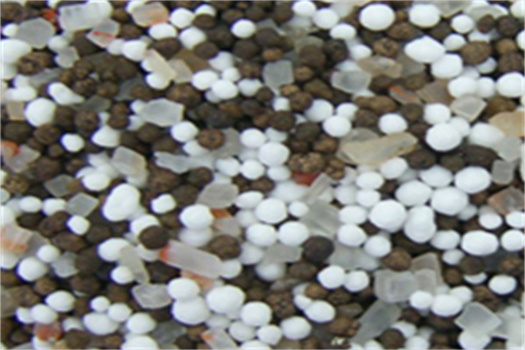

The BB fertilizer production process is simply the mixing of several types of fertilizers without chemical reaction. It has simple production process, and the required equipment is relatively affordable. In addition, the finished BB fertilizers made by our equipment has uniform particle size, low moisture content and good particle strength.

What Are Raw Materials & Application of BB Fertilizer Production Line?

Raw Materials: It is suitable for various chemical materials such as urea, diammonium phosphate (DAP), potassium chloride (KCL), monoammonium phosphate (MAP), triple superphosphate (TSP), superphosphate (SSP), ammonium sulfate, phosphate, etc. Besides, producing BB fertilizer can also use zinc, copper, magnesium, iron or other organic or inorganic matter.

Application: You can apply the bulk blended fertilizer production line mainly in the production of BB fertilizer, compound fertilizer, formulation fertilizer, drip irrigation fertilizer, chemical products, feed and other industries.

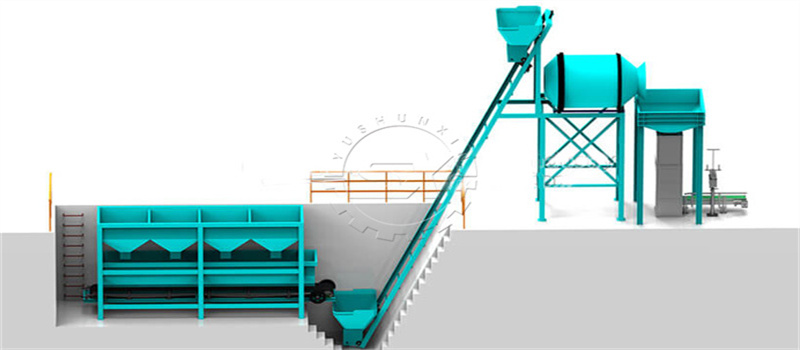

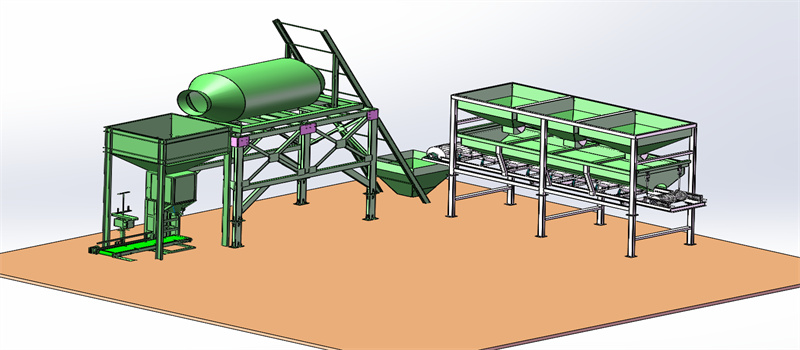

Main Equipment of BB Fertilizer Production Line

1. Batching System

Batching system is mainly consists of feeding system, weighing device, stock bin and conveyor belt. We have two types of batching machines: static batching machine and dynamic automatic batching machine.

- Dynamic automatic batching machine is appropriate for the sites of continuous batching, which have higher requirements on the continuity of the batching. Meanwhile, it doesn’t allow the intermediate batching to stop, and the requirements for the proportioning of various materials are strict.

- Static batching machine is suitable for the sites of quantitative batching, which have low requirements for batching time, and process feedstock in batches at intervals.

2. Mobile Belt Conveyor

Mobile belt conveyor has the advantages of strong conveying capacity, long conveying distance, simple structure, easy maintenance, low cost and good versatility. Meanwhile, it can easily perform the programmatic manipulation and automatic operation, and you can widely use it in metallurgy, coal, transportation, chemical industry and other departments.

3. BB Fertilizer Mixer

The most important part is mixing during the BB fertilizer production. Thus, our factory has developed two types of mixer equipment: BB fertilizer mixer and drum type BB fertilizer mixer. Moreover, these machines have simple structure, easy operation and convenient maintenance, low equipment investment and energy consumption.

- BB fertilizer mixer overcomes mixing material lamination or diversion caused by variable specific gravity and granularity of raw materials, increasing batching accuracy.

- Rotary type BB fertilizer mixer designed by our company is capable of continuous production with a capacity of 30-40 tons/hour. It is extremely efficient and wear-resistant, and we can provide with anti-corrosion lining to meet the needs of the customers.

4. Automatic Packing Machine

We specially design, produce and customize automatic packing machine to meet the needs of various materials, which is an intelligent fertilizer production machine. In addition, you can use it in industrial and agricultural automation production for automatic quantitative packaging. What’s more, computer can manage and complete the entire weighing process automatically.

What Are The Advantages of Using BB Fertilizer Production Line?

Get Free Quote Now!