Bio-organic Fertilizer Production Line

Why Does Agricultural Production Need Bio-organic Fertilizer Production Lines?

If you want to improve the quality of crops, welcome to try our Shunxin bio-organic fertilizer production line!

The bio-organic fertilizer manufactured by our production line has the functions of enhancing soil fertility, assisting crops to absorb nutrients, and activating insoluble matters in the soil to make crops absorb and utilize.

The bio-organic fertilizer processed by microbial action can produce a variety of active and anti-disease substances. Thus, it has a good stimulation and regulation of the growth of crops, reduces pests and diseases, and improves the quality of agricultural products.

The Requirements for Choosing Strains & Raw Materials of Bio-organic Fertilizer Production Line

- Animal manure: chicken, cattle, horse, sheep, pig dung, etc.

- Agricultural products waste: bran, fruit residue, bagasse, mushroom residue, rotten vegetables, moldy feed, etc.

- Food processing waste: wine lees, beer distiller’s grain, vinegar residue, cassava residue, drug residue, oil residue, etc.

- Organic garbage: kitchen waste, slaughterhouse waste, etc.

- Municipal sludge: riverway sludge, pond mud, sea mud, lake mud, sewage sludge, filter mud, etc.

Auxiliary materials are mainly used to adjust the material moisture, C/N, PH value, and permeability, which are usually dry, fine, high carbon content, such as various crop stalks, leaves and weeds, straw, peanut shells, sawdust, etc.

The strains for bio-organic fertilizer production, first of all, must have the performance of promoting solid organic matter fermentation, that is, the fermentation effect makes organic waste decomposition, deodorization and drying. The strains commonly used for solid organic matter fermentation are as follows: filamentous fungi, basidiomycetes, yeasts, actinomycetes, bacillus, etc.

Multiple species inoculants are often used in actual production, including cellulose-decomposing bacteria, nitrogen-fixing microorganism, phosphate solubilizing microorganism, photosynthetic bacteria and some of the above strains made of starter culture.

Top 2 Bio-organic Fertilizer Production Techniques You Should Know

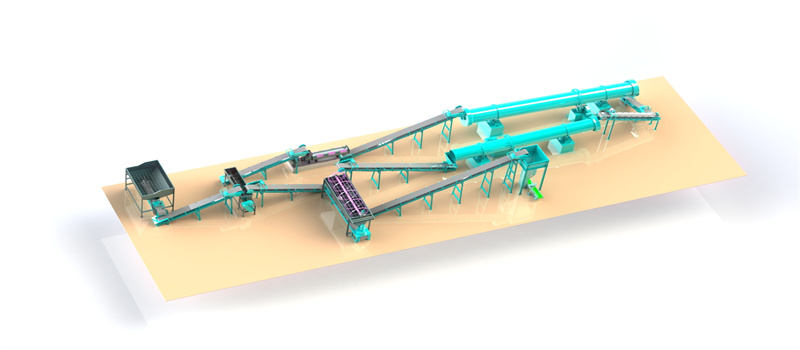

The methods and effect of fermentation and decomposition of organic materials are closely related to the production process and equipment. Shunxin has two main production processes used in production.

If your plant is in this situation with low budget and inadequate infrastructure, we recommend you to choose the windows composting process. You need to blend materials and make long stacks with 2-3 meters width and 1-1.5 meters height under the fermentation shed or on the flat ground in the open air, and compost the stacks depending on the temperature.

If you have a certain scale of plant and want to produce large output and high quality bio-organic fertilizer, we suggest you to choose groove type aerobic fermentation process. Depending on the composting equipment, the general fermentation grooves are 5-10 meters long, 3-30 meters wide and 0.8-3 meters high. Several grooves are placed in a closed or semi-closed plant.

Each groove need to be install a ventilation pipe at the bottom and maintain forced ventilation regularly in order to promote the rapid propagation of aerobic microorganisms. You need to turn the compost regularly, about 3 days, and the fermentation cycle should last 15-20 days. The temperature gradually decreases from a maximum of 70℃ to about 40℃, indicating that the substances have decomposed.

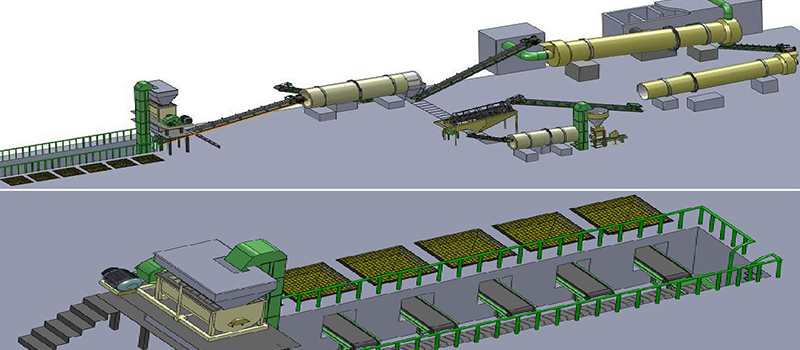

Process of Bio-organic Fertilizer Production from Livestock Manure

The detailed working flow is as follows.

Preparation of raw material (e.g. Crushing straw; manure dewatering) → Adding microbial starter cultures → Mixing → Building stacks/grooves → Composting & Fermentation → Drying → Screening → Packing/Granulation production line (Granulating → Drying → Cooling → Adding functional bacteria again → Coating → Packing)

Equipment Selection Recommendation of Bio-organic Fertilizer Production Line

1. Wheel Type Compost Turner

The wheel type compost turner is ideal for large scale production of bio-organic fertilizer. The largest turning width can reach 30 meters and the single yield is highest. Compared with the traditional compost equipment, the energy consumption is lowered by 70%. Thanks to single groove work, the production cost is greatly reduced.

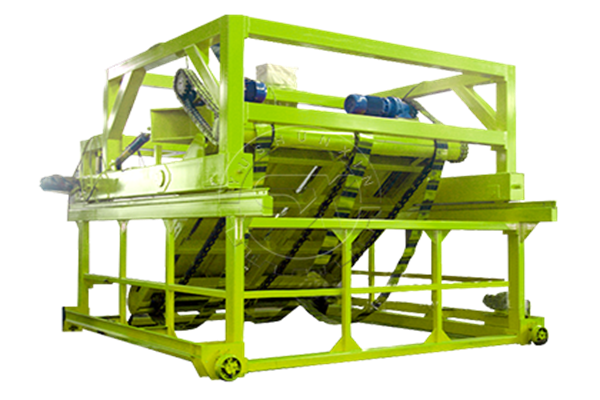

2. Chain Plate Type Compost Turner

If you don’t require granulation but want to make high-quality bio-organic fertilizer powder, this composting machine is perfect for you. The chain plate type compost turner offers very strong processing capacity, high working efficiency, and finer powder than conventional groove type compost turners.

3. Self-propelled Stacker

If you have a small farm or plant with low budget, try crawler type compost turner or moving type compost turner! These two fertilizer production modes are the most economical to save the civil construction and production costs at present.

4. Disc Granulator

Disc granulator is one of the hottest products in our company currently. It has evident classification effect, affordable price, high material suitability, and the granulation rate is more than 90%. There is only one problem that the fineness and uniformity of the material has certain requirements. It’s best to use with a crusher.

5. Die Granulator

Die granulator does not need drying or crushing processes, which saves equipment costs and simplifies operation. The granulation rate is up to 97%. It has high particle strength, neat shape, and almost no return material. If you have requirements for bio-organic fertilizer pellets, you can choose this one.

Shunxin is a professional manufacturer of bio-organic fertilizer equipment, providing customers with good quality, affordable price and after-sales support. If you are interested in knowing more about bio-organic fertilizer equipment model, quotation and other details, welcome to consult online customer service for free at any time!

Get Free Quote Now!