Economical organic fertilizer production equipment you must know

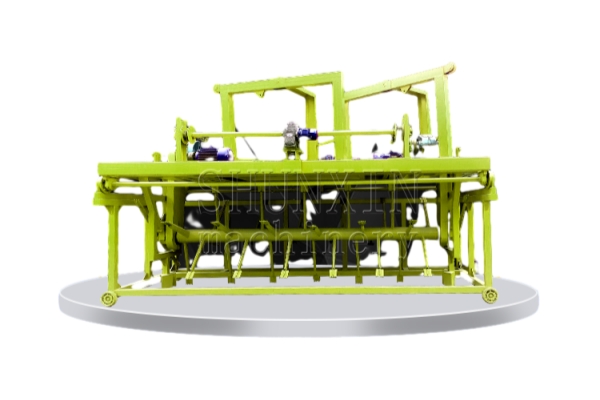

Shunxin crawler type compost turner is a type of large scale composting machine in the windrow fermentation mode, which is the most economical fertilizer manufacturing mode of saving civil construction and labor resources.

How Does A Crawler Type Compost Turner Work?

Crawler Type Compost Machine

On on hand, the diesel engine passes a portion of power through the belt pulley for deceleration to the turning cylinder. On the other hand, the diesel engine sends another part of power to drive the hydraulic pump.

Hydraulic pump, the clutch and walking motor form the hydraulic loop system, which is useful to raise and fall the cylinder. Moreover, the diesel engine drives the entire machine to work or stop, and self-propelled movement.

While working, a worker in the cab drives this compost machine by operating the valve groups. More importantly, the functional instructions are as follows:

Cylinder of Crawler Compost Turner

The cylinder simply has two reverse spiral bands with many throwing teeth and the middle spindle. Firstly, rotation of the cylinder will bring materials together in the center, and then makes materials backward by turning and throwing.

As a result, you can fully mix materials on the top layer with the internal ones. Then, materials have sufficient access to oxygen. Thus, in order to accomplish the fermentation process, you require to keep raw material mixing, ventilation, aeration and turning while using the crawler type compost turner.

Tips for Using A Crawler Type Compost Turner to Make Fertilizer

The crawler type compost machine should travel at a slow speed in theory. However, due to the different materials and moisture content, the driver can select the suitable speed based on the actual situation to obtain the optimum performance.

When this kind of self-propelled composter starts, you should make it rotate without any loads for 3-5 minutes, keep it running for 1 minute after adjusting the walking speed, and then carry out composting works.

You need to make the machine ride across the materials’ stacks. Forced composting when facing the obstacles is forbidden! Furthermore, the right way is that you should quickly turn the speed button to slow down or stop walking, and the crawler type compost machine is in a parking state.

Here, there is only the main shaft working in place to quickly throw the materials backwards without resistance.

Pay attention to prevent straws or other materials from twining on the main shaft of the crawler type compost turner.

If you find there is the rotating shaft entangling with materials, you ought to stop working in time. And after cleaning the obstacles, you can continue composting works. Don’t compost piles or go back by force! Otherwise, this will seriously damage the components of the crawler type composter.

What Are The Outstanding Features of Crawler Type Compost Turner?

1. Advantages Compared to Other Composters

2. Reasonable Structure Composition

Crawler type composting machines have an acceptable construction, with balanced force and easy operation, which are better suitable to the different sites. Meanwhile, this compost machine is equipped with a cab that can separate the heat and odor creating from composting, which is greatly friendly to workers.

The distinctive crawler design overcomes not only the low output problems of typical moving type composting machines, but also high cost disadvantages accessories like the usual chains and grooves. Thus, it can increase the efficiency and product quality of organic fertilizer plants.

The combination of the later crushing function is this equipment’s excellent technology. Moreover, the crawler type compost turner has spiral belts with teeth, which makes materials continues dewatered and crushed. Therefore, it can improve the crushing efficiency and reduce equipment costs, and fundamentally solve the problem of restricting the production capacity of the crushers.

3. Reliable Components & Performance

Soft Starting Function

Soft Starting Function

The crawler type compost turner has functions as soft starting and voltage stabilizing, which provides dependable overload protection for the engine. In addition, soft start avoids or reduces the shock and vibration when the composter starts working. Besides, it can also lower the burden of the motor and the reactive power loss of the starting system, lowering energy consumption and extending the service life of the equipment.

Hydraulic Operating System

hydraulic operating system

The entire machine uses a hydraulic operating system. During the walking process, it can automatically adjust the balance. Even if the uneven ground, it will not affect the normal working of the crawler compost machine. Besides, the hydraulic system can better adjust the uniform force, which can largely reduce the damage to the equipment in the vibration situation.

High-quality Components

High-quality Components

You can automatically adjust the height of the turning shaft according to production requirement. What’s more, our equipment frame and components are international standard accessories, so the service life of the crawler type compost equipment is longer than the same manufacturers.

Main Technical Parameters

|

Model |

SXLDF-2400 | SXLDF-2600 | SXLDF-2800 | SXLDF-3000 |

| Turning Width (mm) | 2400 | 2600 | 2800 |

3000 |

|

Turning Depth (mm) |

600-1000 | 1000-1300 | 1100-1400 |

1300-1500 |

|

Windrow Spacing (mm) |

800-1000 | 800-1000 | 800-1000 |

800-1000 |

| Maximum Diameter of Material Particles (mm) | 250 | 250 | 250 |

250 |

|

Power (horsepower) |

85 | 116 | 123 | 156 |

| Working Knife Diameter

(mm) |

400 | 500 | 500 |

500 |

| Working Speed (m/min) | 6-10 | 6-10 | 6-10 |

6-10 |

| Capacity (m³/h) | 500-700 | 1000-1200 | 1100-1300 |

1500 |

Get Free Quote Now!