Drum Granulator

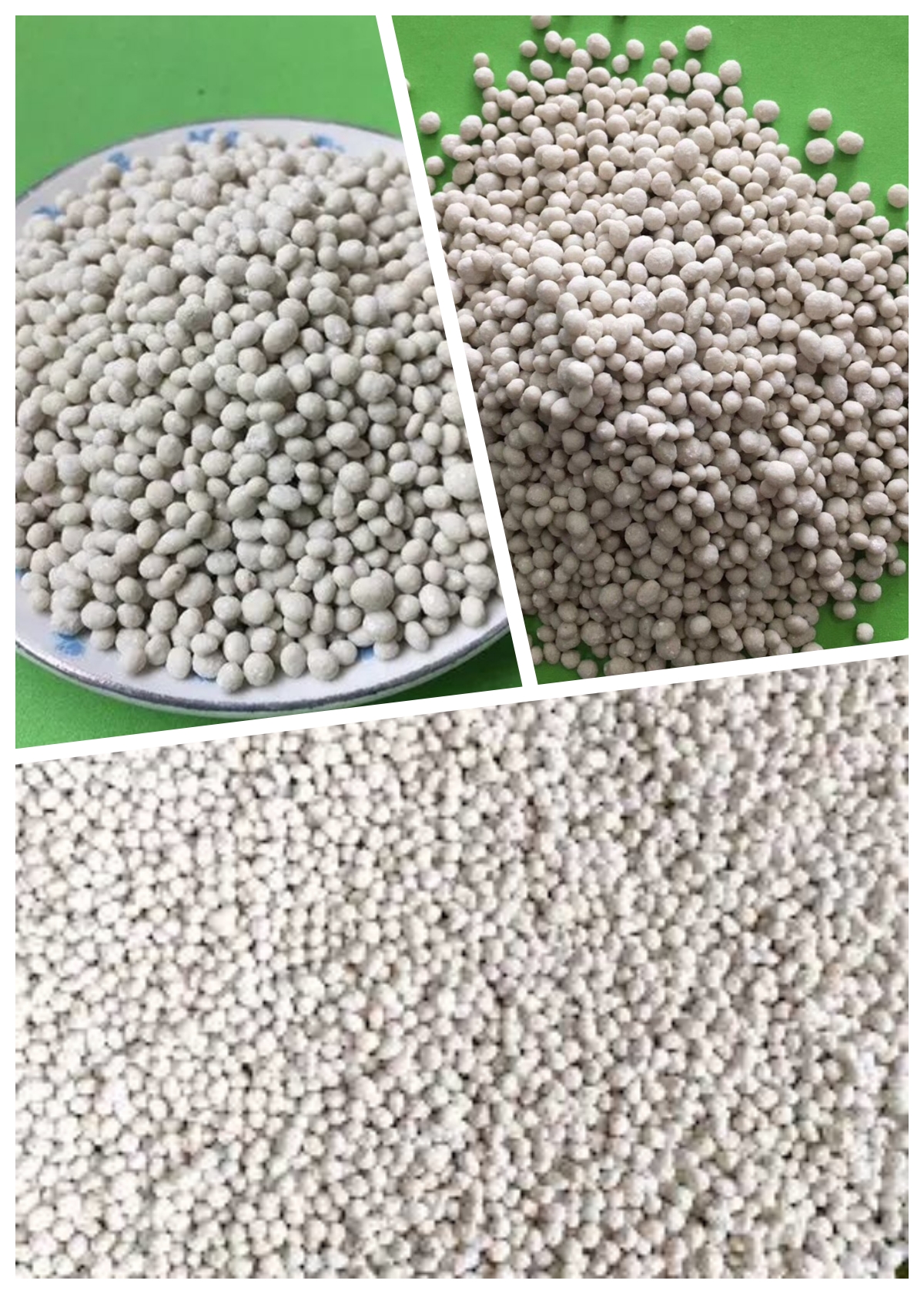

Excellent Compound Fertilizer Made by Our Drum Granulation Equipment!

Rotary drum granulator is a molding machine that can make material to a specific shape. It is also one of the key equipment in compound fertilizer industry. Furthermore, this machine has good appearance quality, corrosion and wear resistance, low energy consumption, long service life, simple operation and maintenance, etc.

Our company specializes in producing compound fertilizer granulating equipment, and can customize the entire production line to meet your specifications. Similarly, our main components and wearing parts are constructed of high quality wear-resistant materials and advanced processing technology, so that the equipment is durable and wear-resistant, is well sold at home and abroad, and the majority of users recognize us as good service!

What Is The Application of Drum Granulator?

Rotary drum granulator is generally used for fertilizer granulation, especially for large compound fertilizer production lines. The final quality of fertilizer granulation manufacture is guaranteed due to regular particle formation. In addition, it can also be used for various forms of granulation, including hot and cold granulation and the production of high-medium-low concentration compound fertilizer, especially two nutrients compound fertilizer (NP, NK, PK) and NPK fertilizer.

Raw materials with low solubility include calcium chloride, ammonium sulphate, potassium sulphate, potassium chloride, etc.; high solubility are urea, ammonium nitrate, ammonium phosphate, etc. It can also be combined with some organic matter and medium and micro elements as needed.

Construction of Drum Granulator

The Operation Way of Drum Granulator

The main operation way is wet type granulation:

- on one hand, you can admit stream and ammonia gas access, or add with phosphoric acid or nitrogen solution, phosphoric acid slurry, etc., to complete the compound fertilizer granulation process of chemical reaction and heat supply in the cylinder;

- on the other hand, you can choose the cold granulation process of compound fertilizer that takes a small amount of moisture supplement.

The materials required for granulation are agglomerated into balls by the rotating movement of the cylinder, which generates extrusion pressure between the particles at a certain humidity and temperature.

How Does A Drum Granulator Work?

- The main motor drives belt and pulleys, and the reducer drives the drive shaft. The split gears installed on the drive shaft engage with large gears fixed on the body.

- The raw materials enter the inlet through the conveyor and get better mixing and granulation effect with the continuous rotation of the drum.

- Under the action of extrusion pressure and rolling, the powder becomes particles. Besides, you need spray certain liquid, making other powder around it attaching to form the final products.

- You should position the machine at a slight angle to facilitate granules discharge from the outlet.

Features of Drum Granulator

Design Parameters of Rotary Drum Granulator

|

Model |

Power

(kw) |

Diameter

(mm) |

Length

(mm) |

Installation

Angle |

Rotary Speed (r/min) | Capacity (t/h) |

| SXZGZ-1240 | 5.5 | 1200 | 4000 | 2-5° | 17 |

1-3 |

|

SXZGZ-1560 |

11 | 1500 | 6000 | 2-5° | 17.5 | 3-5 |

|

SXZGZ-1870 |

15 | 1800 | 7000 | 2-5° | 11.5 | 5-8 |

| SXZGZ-2080 | 18.5 | 2000 | 8000 | 2-5° | 11 |

8-15 |

|

SXZGZ-3210 |

37 |

3200 | 10000 | 2-5° | 9.5 |

15-13 |

Get Free Quote Now!