Organic Fertilizer Equipment

Production Manufacturer

Among the various available organic waster, chicken dung stands out as a high-nutrient source for fertilizer production. Because it contains a lot of organic matter, hydrogen, phosphorus and potassium and other nutrients. But if chicken manure is not treated, it can have serious consequences for crops. Thus, many fertilizer plants or farms seek the solution how to make organic fertilizer by chicken manure. There is no doubt that the most practicable approach for turning chicken manure into organic fertilizer is to employ organic fertilizer processing equipment.

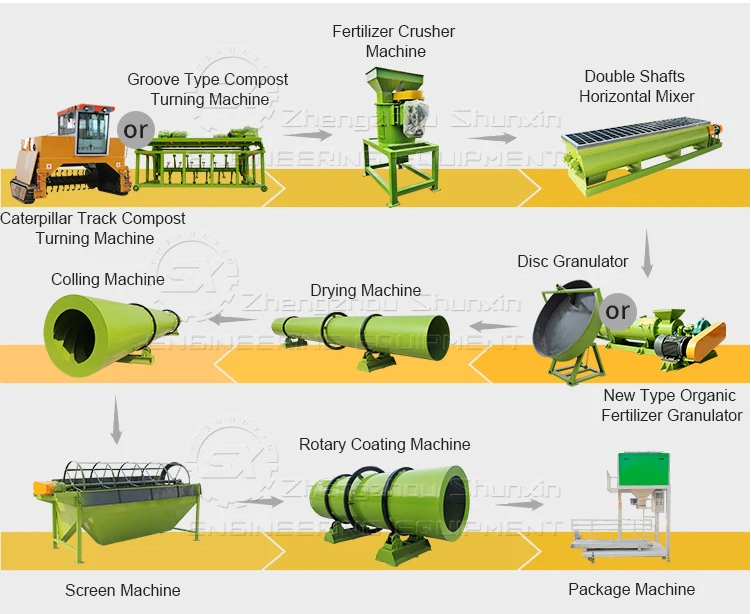

6 Steps to Chicken Manure Processing with SX Organic Fertilizer Equipment

There are six essential steps involved in chicken manure processing using organic fertilizer equipment. If you want to make out how to make organic fertilizer by chicken manure, please carefully read this page!

Step 1Collection and Segregation Process from Chicken Manure

Chicken manure dewatering is an essential step in the processing of chicken manure, aiming to remove excess moisture from the collected manure. This process offers several benefits, such as reducing odor, improving handling and storage, and facilitating subsequent composting or further processing. By using specialized equipment, you can efficiently gather and sort the manure, ensuring that impurities are removed, setting the stage for the subsequent stages of processing.

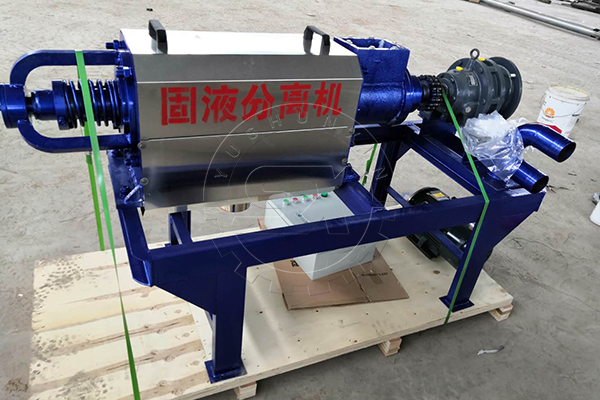

The process of dehydrating chicken manure mainly uses SX screw press dewatering machine or a drum dryer.

Our solid-liquid separator can control the speed and moisture content of chicken manure, allowing wastewater to squeeze out of the mesh screen and flow out of the drainage pipe. In comparison to inclined dewatering machine, this dewatering equipment disposes chicken manure with higher solid content. It can reduce moisture from more than 70% to 30-40%. More importantly, the key part — the screw press, is made of 304 stainless steel, which is corrosion-resistant and has a long service life.

In addition, the drum dryer can reduce the moisture content of chicken manure from 70-75% to below 8% in a short period of time. However, chicken manure has high moisture content and high viscosity. If you directly dry it, it will cause a large amount of materials to stick to the internal cylinder wall. So it is best to first use a dehydrator to reduce the moisture content of chicken manure to a certain extent before drying, and the dry chicken manure will enter the next processing stage or be for sale.

Step 2Compost And Fermentation Process from Chicken Manure

Compost fermentation is a vital step in converting the chicken manure into organic fertilizer. In this process, chicken manure is placed in fermentation grooves or is piles up into stacks. It is important to monitor and maintain the right conditions, such as temperature, oxygen levels, and moisture, for microbial activity to break down the organic matter. Regular turning or stirring of the compost pile will help accelerate decomposition and ensure proper aeration.

Rail type compost turner is suitable for fertilizer plants or farms on a medium and large scale to treat chicken manure. This kind machine has a high degree of automation, fast working efficiency and the weather will never affect it. On the other hand, if you run a small fertilizer plants with limited workshop space, you can choose windrow type compost turner. We can customize the cab, air conditioner and sprinkling device according to your requirements.

Step 3Crushing and Mixing Process from Chicken Manure

After fermentation, you need to crush the compost of chicken manure into finer particles to enhance its nutrient availability and facilitate uniform mixing. So we advise compost grinders for this purpose. Additionally, during this step, it is common to add other materials like organic matter, NPK elements, microelements, or additives to improve the overall quality of the compost mixtures. Therefore, you may need a fertilizer mixer.

For example, our new type vertical crusher suits especially for high moisture materials and is not easy to block. Moreover, the crushing blades adopts special material for long service life. Then, the disc mixer is also a good option for blending organic fertilizer. It has high work efficiency and less occupied area. Besides, the mixing blade adopts high-wear resistant special alloy.

Step 4Granulation Process from Chicken Manure

Granulation is the process of making the mixtures into solid pellets in many shapes like balls or columns under the mechanical force or pressure. This step improves the handling, storage, and application of the organic fertilizer. We recommend specialized equipment, such as organic fertilizer granulators. Moreover, we have a wide range of models for you to choose. If you want to shape the materials into uniform granules, you can appropriately add binding agents if necessary.

Step 5Drying and Cooling Process from Chicken Manure

If you make granules from chicken manure by dry granulation machine — flat die granulator, you needn’t the next dry process. Besides, chicken manure pellets contain higher moisture content after granulation by new type organic fertilizer granulator, pan granulator, etc. Hence, in order to extend the shelf life, you needs to do dry process, usually by a rotary drum dryer to evaporate the water in the particles through hot air. Then you can get granular fertilizer with the moisture of less than 10%. Furthermore, the dry particles are hot and need to be cooled. Drum coolers are often used to cool pellets to room temperature for easy packaging and storage.

Step 6Packing Process from Chicken Manure

The final step in chicken manure processing with organic fertilizer equipment is packaging the dry granules. SX automated bagging machines transform packaging, streamlining processes and boosting efficiency. They handle bulk fertilizers, filling bags swiftly, ensuring precision in weighing, and sealing accurately. Automation cuts labor needs, maximizing production capacity, meeting market demands, and lowering costs for fertilizer producers.

To be honest, you can choose single bucket packing scale for the bagging of low-dose finished organic fertilizer. Furthermore, you can buy a packing production line about automatic packing scale and robotic palletizer, for weighing, filling, sewing and transportation of large-scale fertilizer production.

The use of organic fertilizer equipment streamlines the process and ensures that the end product is safe, effective, and easy to handle. By following these six essential steps of separation, fermentation, crushing and mixing, granulation, drying and packaging, chicken manure becomes a valuable resource for agriculture production. Dear customers, please contact us as soon as possible! Our professional team will be happy to serve you and provide you with the best solution of organic fertilizer production.