바이오 수정기 생산 기술

Why Is Bio-fertilizer Favored by Many Fertilizer Factories?

비io-fertilizer, is a product that contains both nutrient elements required by crops and microbes, and is a combination of biological, 본질적인, and compound matter. It can be used in place of chemical fertilizer and provides all of the nutrients required for plant growth and development.

Bio-fertilizer has a long-lasting effect, improves the utilization rate of fertilizer, reduces agricultural production costs, increases output and income, improves product quality and soil, and reduces environmental pollution. It is the ideal fertilizer for pollution-free agricultural production and organic agricultural production, and has broad development and application prospects in sustainable agricultural development.

New Bio-fertilizer Production Technology And Process

Why Many Fertilizer Plants Apply Our Bio-fertilizer Production Technology?

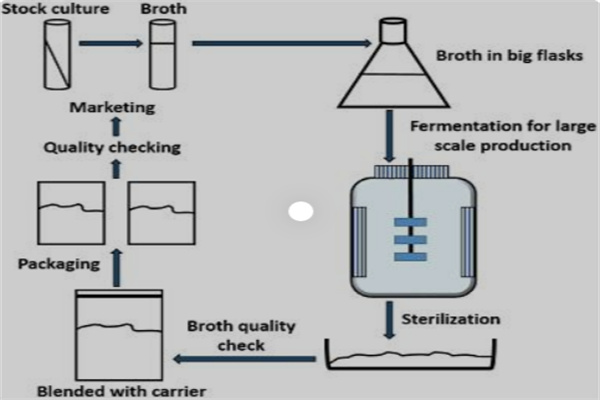

- The general traditional bio-fertilizer production process is: strain preservation → culture medium & activation → liquid fermentation → 포장 by using physical adsorbents or dilution method in a certain proportion.

- The construction of such a manufacturing plant involves the establishment of a bioclean room, air compressor, fermentation pot and filter. It is difficult to control culture and fermentation conditions, as well as the quality of strains with large investment 그리고 비용.

The bio-fertilizer production technology adopted by our company requires the addition of 미생물 제 that promotes the decay and decomposition of organic materials during the fermentation process, as well as achieve the purpose of deodorization. 게다가, bacteria added in the post-treatment process with specific functions can enhance the effect of finished products. This is an excellent option for small and medium scale fertilizer producers, particularly generating bio-organic and inorganic fertilizer.

Bio-fertilizer Production Technique

Most bio-fertilizer production enterprises employ the groove type fermentation method. 게다가, other fermentation methods like windrows composting method 그리고 seal pot fermentation method, also occur in the bio composting process.

- 메모:

- The adjustment of moisture, C/N 비율, 온도, and the use of microbial agent is the key to the production process. 특히, the application of microbial agent directly affects the cycle of fermentation and the degree of decomposition of materials.

- The composted product basically realize the harmless production, which is also conducive to the survival of the functional bacteria added in the post-treatment procedure.

During the post-treatment, most enterprises add functional bacteria for rebatching, and the products are mainly in powder form, but some companies apply roller granulation or extrusion granulation.

- 메모:

- Granular products overcome the shortcomings of poor appearance of powder products and improve the commodity of the products.

- 그럼에도 불구하고, it also increases the production cost of enterprises and has a certain impact on the survival of effective bacteria.

Specific Process Flow

There are three basic types of bio-fertilizer manufacturing processes:

After expand culture, microbes with specific functions (예를 들어. rhizobium, potassium bacteria, phosphate solubilizing bacteria, 등.) combine with microcarriers (like grass charcoal or vermiculite) to make inoculants for small scale production.

Working Flow:

Microbial strains fermentation → Physical adsorbents (예를 들어. grass charcoal and 비석) → Mixing in certain proportion → Crushing → Microbial Agent

Microbes are mixed with organic matter, such as animal manure, grass charcoal and brown coal.

Working Flow:

- 탈수 (예를 들어. 비료) → 눌러 터뜨리는 → 상영 → 혼입 (미생물 제, 유기 폐기물과 빨대) → 퇴비 → 상영 → 포장/과립화 생산 라인 → 포장

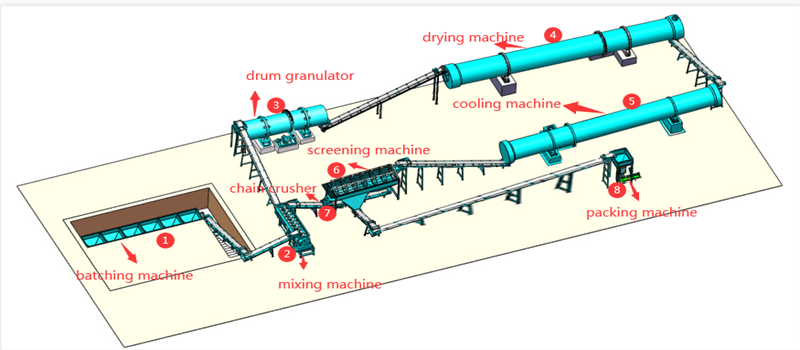

Microbes are mixed with inorganic matter (예를 들어. chemical fertilizers and micronutrients) to make the base fertilizer and the topdressing for 대규모 생산.

Working Flow:

- 배치 (NPK) → 혼입 with bacteria → 과립 → 건조 & 냉각 → 상영 → 포장

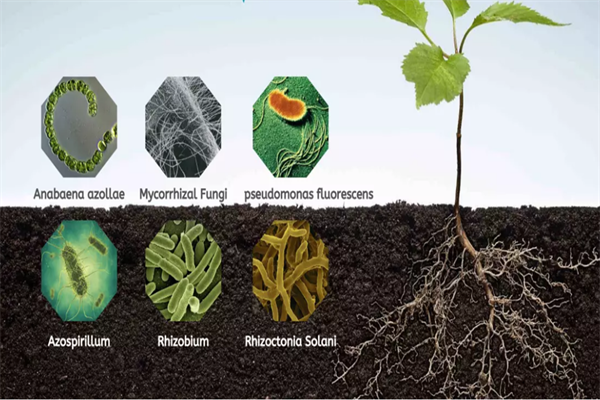

What Species of Bacteria Can Use in Bio-fertilizer Production?

Microbial strains are the core of bio-fertilizer products, which are generally used in two parts during the production process.

- Adding microbial agents in the composting process is to achieve the function of decomposition and deodorization. They mostly contains compound bacteria, such as photosynthetic bacteria (PBS), lactic acid bacteria (LAB), saccharomycetes, actinomycetes, penicillium, trichoderma, 등.

- The functional bacteria are added to the semi-finished products during the post-treatment, 좋다 nitrogen-fixing bacteria, phosphate solubilizing bacteria, silicate bacteria, lactic acid bacteria, pseudomonas 또는 actinomycetes, play a specific effect in fertilizer production.

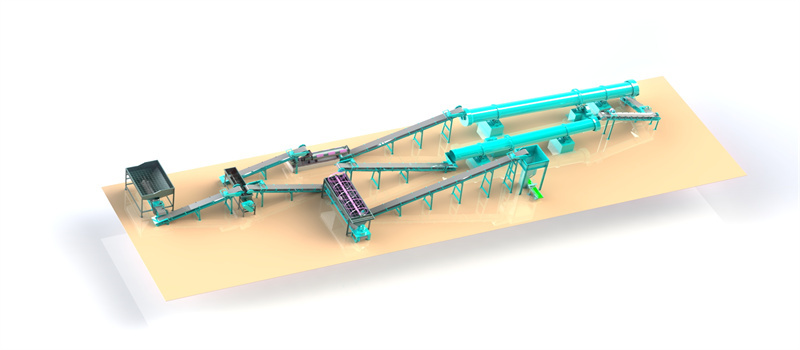

Bio-fertilizer Production Equipment

- 1

퇴비: 그루브 타입 퇴비 터너, 이동 유형 퇴비 터너, organic fertilizer fermentation pot, 등.

- 2

배치: 정적 배치 머신 및 동적 자동 배치 시스템, 로더 타입 피더, 등.

- 3

눌러 터뜨리는: 새로운 유형 수직 분쇄기, 반 습식 재료 크러셔, 끈 분쇄기, 등.

- 4

혼입: 수평 믹서, 디스크 믹서, 단일 샤프트 믹서, BB 비료 믹서, 등.

- 5

과립: 디스크 입력기, 로타리 드럼 세금질, 평평한 다이 세포터, 새로운 유기 유기 비료 입금기, 유기 비료 연마기, 등.

- 6

Other Auxiliary Equipment: 건조기와 쿨러, 로타리 스크리닝 머신, 운송 기계, 로타리 코팅 기계, 자동 정량적 포장 스케일, 자동 팔레타이저, 먼지 수집가, 등.

Quality Bio-fertilizer Made by Our Production Technology!

지금 무료 견적을 받으십시오!