비료 생산 공정

현대 농업의 빠른 발전으로, 유기 및 화합물 비료의 사용이 점점 더 중요 해지고 있습니다.. 따라서, 많은 농업 생산자들은 유기 및 무기 물질을 고품질 비료로 성공적으로 전환하는 방법을 배우는 데 관심이 있습니다..

유기농 및 화합물 비료의 전체 생산 공정을 소개 할 것입니다., 관련 장비뿐만 아니라, 우수한 장비를 추천합니다.

유기 비료 생산의 두 가지 범주

유기 비료 생산 장비는 처리하는 것입니다 원료 유기 비료에 유기물이 풍부합니다, 가축 분뇨와 같은, 슬러지와 쓰레기, 설탕 공장에서 진흙을 걸러냅니다, 바이오 가스 잔류 물과 밀짚 톱밥.

완성 된 유기 비료에는 두 가지 주요 측면이 있습니다: 유기 분말 비료 그리고 유기 과립 비료.

1. 유기농 분말 비료 생산 공정

유기 전력 비료 생산의 전체 과정에는 간단한 세 가지 프로세스가 포함됩니다.: 전처리, 1 차 발효 그리고 치료 후.

퇴비화 전에, 원료를 처리해야합니다 체적 불순물을 제거합니다. 그들은 운송 마당에, 그들은 무게를 측정하고로 보내집니다 믹싱 장치, 폐수 및 미생물 제와 혼합되는 곳.

게다가, 공장은 수분 함량을 조정해야합니다, 원료 조성에 따른 탄소 및 질소 비율 및 다음 과정을 수행하십시오..

혼합 재료는 발효 부위로 전송됩니다. 운송 기계.

산소 공급을 위해 강제 환기를 채택해야합니다, 매번 퇴비 2 날 특정 물과 영양소의 공급으로, 발효 온도를 제어합니다 50℃ -65 5 호기성 발효를 위해.

이 프로젝트는 발효주기가 있습니다 7-15 날. 반제품이 배출 된 후, 그들은 다음 과정에 들어갈 준비가되었습니다.

그런 다음 체적 자료를 보낼 수 있습니다 건조기 건조.

마지막으로, 완제품은 유기물의 양에 비례하여 미세 영양소의 첨가와 혼합 된 다음 포장 판매를 위해 저장.

결론적으로, 완전한 과정은 다음과 같습니다: 탈수 (신선한 식물 & 비료) → 눌러 터뜨리는 → 상영 → 혼입 (예를 들어. 미생물 제, 가축 분뇨와 밀짚 혼합) → 퇴비 & 발효 → 온도 조정, 강제 초안 및 수분 함량 → 상영 → 완제품 → 포장 → 저장

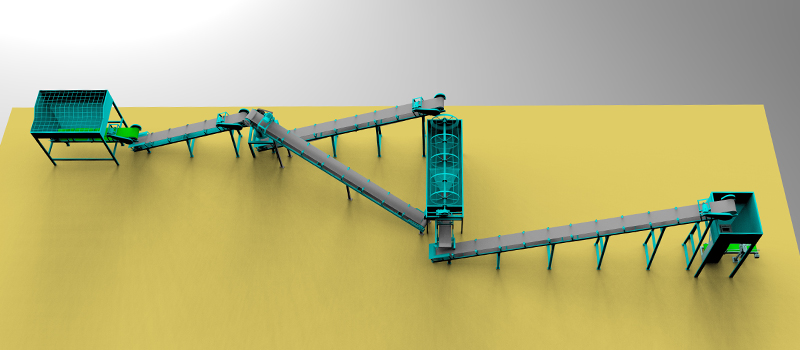

유기농 분말 비료 장비

유기 전력 비료의 생산은 비교적 간단합니다. 장비에는 5 개의 주요 장치가 포함됩니다: 유기 비료 발효 퇴비 기계, 로더, 피더 머신, 파쇄기, 그리고 스크리닝 머신 (로타리 스크리너 또는 진동 스크리너). 이 기계는 연결해야합니다 벨트 컨베이어 완전한 생산 라인을 형성합니다.

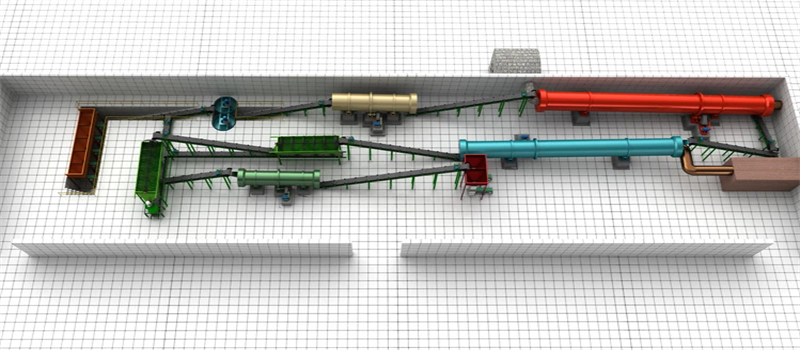

2. 자주 사용하는 유기 과립 비료 생산

전체 유기 과립 비료 생산 공정은 대략 다음 단계로 나눌 수 있습니다.: 퇴비 → 눌러 터뜨리는 → 혼입 → 과립 → 건조 → 냉각 → 상영 → 재발 → 코팅 → 포장.

각 생산 공정에는 합리적인 장비가 필요합니다, 균형 잡힌 생산 시스템을 초래합니다.

유기 과립 비료 생산 공정

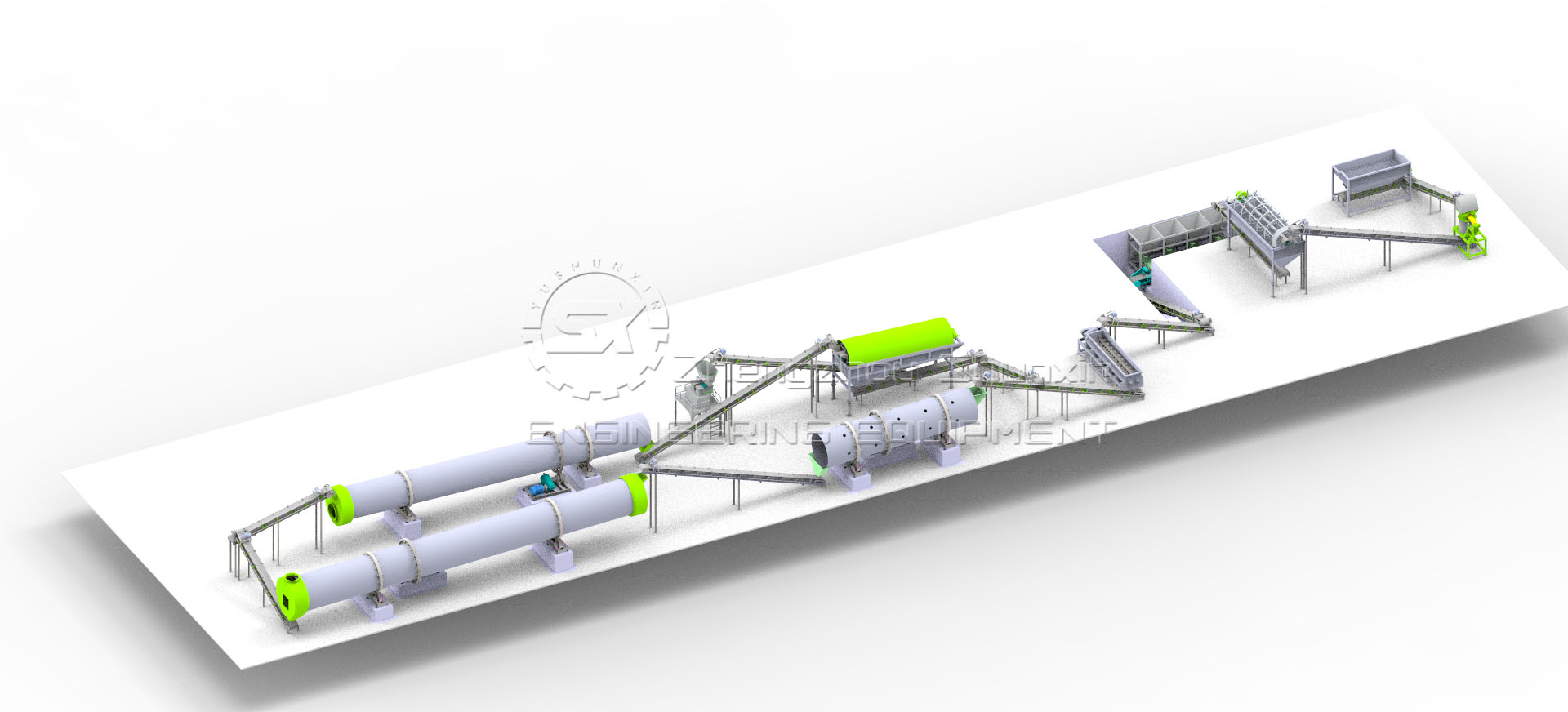

에너지 효율적인 화합물 비료 생산

우리 회사는 다음을 제공합니다 복합 비료 생산 소형 레이아웃이있는 장비, 과학적이고 합리적인 디자인, 고급 기술. 그들은 에너지 절약 및 소비 감소의 장점이 있습니다, 환경 오염이 없습니다, 안정적인 작동, 신뢰할 수있는 작동 및 편리한 유지 보수.

원자재의 넓은 적응성으로 인해 복합 비료에 자주 적용됩니다., 제약, 화학적인, 사료 및 기타 산업 과립, 과립율이 높습니다.

복합 비료 생산 공정

과정 복합 비료 생산 일반적으로 포함 할 수 있습니다: 배치 → 혼입 → 과립 → 건조 → 냉각 → 상영 → 재 구축 → 코팅 → 포장.

복합 비료 생산 장비

화합물 비료 생산 장비는 주로 포함됩니다:

- 1

배치: 정적 배치 머신 및 동적 자동 배치 시스템.

- 2

혼입: 수평 믹서, 단일 샤프트 믹서, BB 비료 믹서, 디스크 믹서, 등.

- 3

과립: 로타리 드럼 휘젓는 게이터, 드럼 세포터, 디스크 입자기 및 이중 롤러 압출 입 조산기.

- 4

보조 장비: 건조기와 쿨러, 로타리 스크리닝 머신, 운송 기계, 로타리 코팅 기계, 자동 정량적 포장 스케일, 자동 팔레타이저, 등.

위는 비료 생산 공정의 상세한 도입입니다..

우리 회사는 수년간 비료 가공 장비 생산에 중점을 두었습니다., 그리고 고객의 실제 요구가 만족스러운 장비 구매에 도움이되는 적절한 생산 계획을 개발할 것입니다..

궁금한 점이 있거나 필요한 경우, 주저하지 말고 저희에게 연락하십시오, 우리는 당신을 섬기게되어 기쁩니다!

지금 무료 견적을 받으십시오!