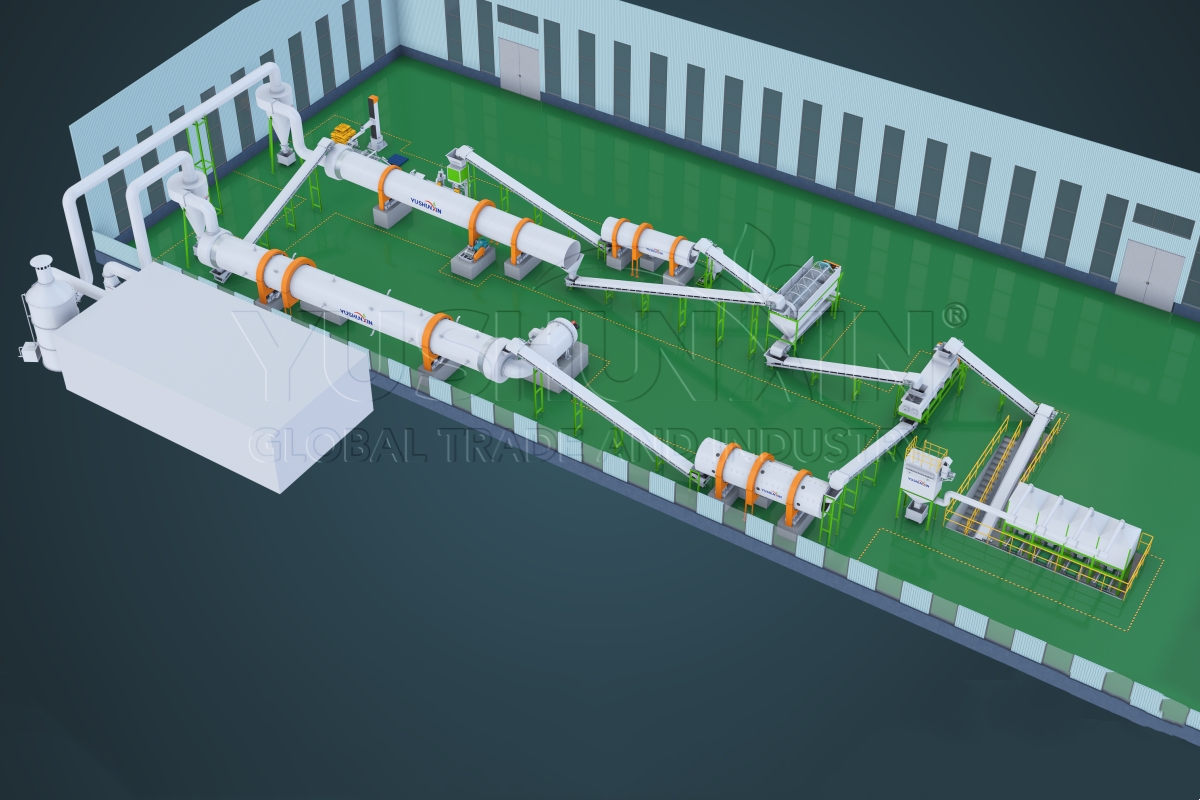

If you are considering how to make compound fertilizer easily or building an medium NPK fertilizer factory, our company designs 20 t/h NPK fertilizer blending production line for producing bulk blended fertilizers. You can rely on our automatic fertilizer equipment for a seamless NPK fertilizer manufacturing process. Also, such a compound fertilizer blending program can save much space and land construction. Furthermore, we provide solutions for NPK fertilizer plant cost optimization and flexible NPK formulas.

If you are considering how to make compound fertilizer easily or building an medium NPK fertilizer factory, our company designs 20 t/h NPK fertilizer blending production line for producing bulk blended fertilizers. You can rely on our automatic fertilizer equipment for a seamless NPK fertilizer manufacturing process. Also, such a compound fertilizer blending program can save much space and land construction. Furthermore, we provide solutions for NPK fertilizer plant cost optimization and flexible NPK formulas.

Who Can Benefit from The 20 T/H NPK Fertilizer Blending Plan?

We offers an efficient and cost-effective solution for bulk blending fertilizer production. Moreover, this 20 tph bb fertilizer mixing line can help NPK fertilizer plant produce high-quality NPK compound fertilizers that meet national and international standards.

For Large Scale Compound Fertilizer Manufacturers

Generally speaking, companies aiming to produce substantial quantities of NPK blended fertilizers can benefit from our 20 t/h compound fertilizer production line. For example, compound fertilizer factory that operates at more than 200 tons per day need such an efficient fertilizer blending program. Annually, this plan can produce 60,000 tons of npk mixed fertilizer. And this high output meets the demands of growing markets. Meanwhile, this production line mainly utilizes NPK mixing technology to optimize raw material utilization and reduce waste of NPK compounds. Besides, our bulk blending fertilizer equipment ensures consistent quality in every batch.

For Clients with Limited Space

Due to tight land resources or high land rents, small and medium compound fertilizer producers in Southeast Asia and Africa need efficient and compact equipment for quick, cost-saving NPK fertilizer plant startups. So we recommend 20 t/h bb fertilizer mixing line. It requires only 1500 ㎡ to cover raw material storage, precise batching, efficient blending, and automatic packaging. Compared to traditional NPK compound fertilizer production lines, our 20 t/h bb fertilizer plant design reduces the footprint by 40%. For instance, our npk fertilizer blender with bucket elevator reduces floor space usage. Moreover, we offer automatic stacking equipment that increases storage efficiency by 60%. Our NPK blended fertilizer production line is easy to install. Consequently, if you want to increase your capacity increases to 30 t/h in the future, you only need to add partial bb fertilizer equipment without extra land acquisition.

$60,000-80,000 Budget to Establish A 20 T/H BB Fertilizer Plant

Don’t worry producing large scale NPK fertilizers with low budget! And our design and efficient machinery offer your a profitable fertilizer blending process. With a budget of $60,000-$80,000, you can efficiently set up a 20t/h bb fertilizer factory, using our bulk blending fertilizer production line. So why low-budget customers choose our NPK fertilizer mixing line?

40%-60% Initial Investment Reduction of Compact BB Fertilizer Mixing System

Our NPK fertilizer blending plant’s modular design reduces your initial investment. Unlike traditional fertilizer granulation processes, the bb fertilizer plant design eliminates the need for high-temperature granulation and drying steps. In other words, it simplifies equipment to batching system, mixers, and packaging lines. So it cuts BB fertilizer machinery procurement costs by 40%-60%. Additionally, because of compact layout, 20 t/h bb fertilizer manufacturing line supports expand NPK production capacity in phases, up to 30 t/h, 40 t/h or 50 t/h. Thus, you can start small and expand as your NPK fertilizer business grows, easing financial pressure.

Flexible NPK Fertilizer Formulas Adjustment for Market Needs

Our fertilizer blending program allows dynamic adjustment of N-P-K ratios, such as switching from 15-15-15 to 20-10-10. After completing a batch of BB fertilizer production, dynamic batching machine with 4 bins in 20 t/h NPK fertilizer blending system can accurately adjust the formula ratio through the PLC device. Therefore, this flexibility allows you to quickly produce crop-specific blended fertilizers without replacing core equipment, avoiding inventory backlog. Moreover, by utilizing local raw materials like potassium chloride and phosphate rock powder, you reduce transportation and storage costs. Consequently, it improves your mixed fertilizer manufacturing process efficiency and enhances your competitiveness in the NPK fertilizer market.

Low Energy Consumption & High ROI of BB Fertilizer Production Plan

Generally, the 20 t/h NPK fertilizer granulation line may spend 300-400 kW electricity. Compared to traditional granulation line, our 20 TPH NPK fertilizer blending process consumes only one-third of the power, about 100-150 kW. Furthermore, the automatic bb fertilizer manufacturing system reduces labor demand by 50%. Also, with a daily output of up to 480 tons, you can meet regional distributors’ demands. Importantly, you can recover your investment in 6-12 months. This quick return is crucial for low-budget clients. Especially in regions with low fertilizer self-sufficiency, like Southeast Asia and Africa, our NPK fertilizer plant design offers strategic advantages.

Aligning with Market Trends & Environmental Standards

Our customers need cost-effective, eco-friendly NPK fertilizer production solutions. So our 20t/h NPK fertilizer plant design includes efficient dust removal and waste gas treatment systems, such as bag dust collectors in the batching process. Also, it can capture dust effectively, ensuring emissions meet environmental standards. Thus, this reduces environmental pollution and lowers your compound fertilizer plant compliance costs. Whatever, our NPK fertilizer manufacturing process aligns with eco-friendly policy. Furthermore, you may benefit from government subsidies for such bulk mixing fertilizer machinery, easing your financial burden further.

Choosing Yushunxin’s NPK fertilizer blending program ensures a cost-effective, efficient, and environmentally friendly solution. As leading fertilizer blending plant manufacturers, we help you establish your NPK fertilizer factory within budget and meet market demands effectively.

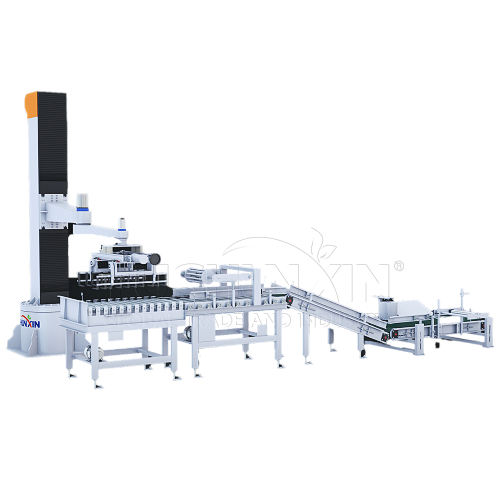

What Is The 20 T/H NPK Fertilizer Mixing Manufacturing Process?

Our engineers design the BB fertilizer production line which includes raw material batching, bucket elevator conveying, efficient blending, precise packaging, and automatic palletizing. And each process around the 20 tons per hour capacity. Besides, you can select to purchase granular chemical fertilizers with 2-4 mm size, such as urea, DAP, MOP, SOP, and optional trace elements like borax and zinc sulfate. Alternatively, you can make NPK powder into uniform particles using a roller press granulator.

5 Steps to Make 20 T/H BB Fertilizer

- 1

Firstly, our automatic batching machine with PLC control system can realize synchronous measurement of 4 warehouses. And this fertilizer batching system accurately control the ratio of nitrogen, phosphorus, and potassium in the NPK fertilizer blending process.

- 2

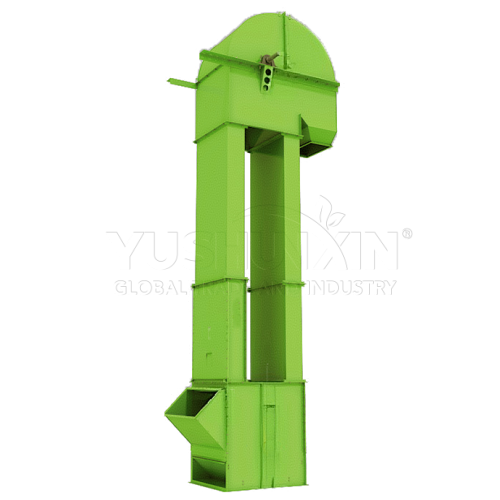

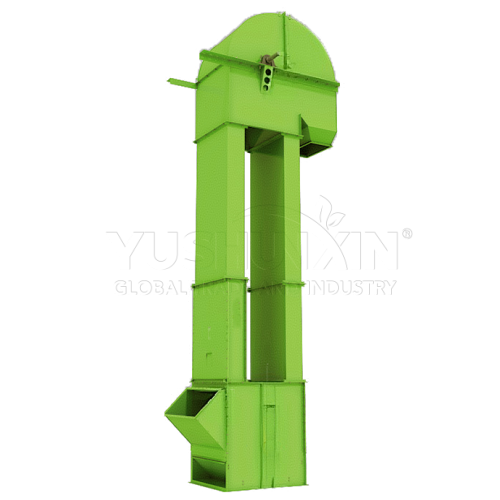

Additionally, we use a bucket elevator to efficiently lift batched NPK compounds to the blending equipment’s inlet, suitable for large-scale continuous bb fertilizer manufacturing processes.

- 3

Thirdly, our bb fertilizer mixing machine adopts a drum-type design for optimal continuous blending. It ensures the bulk blending fertilizer production system produces uniformly mixed fertilizers.

- 4

Then, another bucket elevator sends blended NPK fertilizers to the double bucket bagging machine, which automatically fills bags of 25kg or 50kg with precise weight control. Also, the automatic sewing function ensures secure sealing of bb fertilizer bags.

- 5

Finally, we equip this line with an automatic palletizer that neatly stacks packed BB fertilizers, facilitating storage and transportation in your NPK fertilizer factory.

If you need additional devices like installing dust covers, motor, etc, please contact us. We can customize the 20 t/h NPK fertilizer blending production line to meet your specific requirements.

What Equipment Are Necessary in 20 T/H NPK Fertilizer Blending Production Line?

In the bulk blending fertilizer manufacturing process, selecting the right equipment is essential for efficient production. Our company provides efficient material handling, uniform mixing, and automatic packaging for your NPK fertilizer plant, ensuring high-quality bulk blended of fertilizers.

By applying these essential machines, you can optimize the NPK fertilizer blending production line to enhance productivity, ensure product quality, and minimize labor expenses. Finally, our company provides fertilizer blending plant solutions to support you in establishing a cost-effective and efficient BB fertilizer factory.

Key Equipment Parameters Table of 20 T/H BB Fertilizer Production Line

| Image | Machine | Capacity | Power | Quantity |

|

Dynamic Batching Machine | 20 t/h | 4.4 kw | 4 bins |

|

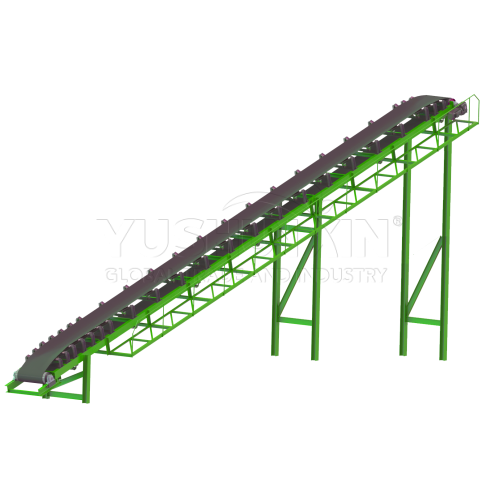

B800-11m Belt conveyor | 5.5 kw | 2 Sets | |

|

10m Bucket Elevator | 2.2 kw | 1 Set | |

|

1.8m*7m Rotary Drum Mixer | 15-20 t/h | 5.5 kw | 1 Set |

|

6m Bucket Elevator | 1.5 kw | 1 Set | |

|

Double Bucket Granule Packing Scale | 12 bags/min | 2.2 kw | 1 Set |

|

High Stacker | 6 cycles/min | 11.2 kw | 1 Set |

|

Bag Dust Collector | 7.5 kw | 1 Set |

Our company offers the 20 t/h NPK fertilizer blending production line to meet your bulk blending fertilizer needs. This production process enables you to produce high-quality bulk blended fertilizers efficiently. With our advanced BB fertilizer equipment from batching to stacking, you can streamline your fertilizer blending process. Our NPK fertilizer plant design focuses on reducing your NPK fertilizer plant cost while maximizing productivity. By partnering with us, you benefit from a leading fertilizer blending plant manufacturer. Contact us to learn how to make NPK fertilizer and elevate your business with our NPK compound fertilizer production line.

Our company offers the 20 t/h NPK fertilizer blending production line to meet your bulk blending fertilizer needs. This production process enables you to produce high-quality bulk blended fertilizers efficiently. With our advanced BB fertilizer equipment from batching to stacking, you can streamline your fertilizer blending process. Our NPK fertilizer plant design focuses on reducing your NPK fertilizer plant cost while maximizing productivity. By partnering with us, you benefit from a leading fertilizer blending plant manufacturer. Contact us to learn how to make NPK fertilizer and elevate your business with our NPK compound fertilizer production line.

Get Free Quote Now!