Liquid Orgaic Fertilizer Manufacturing Process

To be honest, we are the leading organic fertilzer production equipment manufacturer in China. Withal, we specialize in manufacturing liquid organic fertilizer production lines with capacities ranging from 1m³/h to 20m³/h. In recent years, we sell our machines to make liquid organic fertilizer well at home and abroad. Moreover, liquid organic fertilizer production process can handle a variety of organic materials, such as animal manure, humic acid, amino acid, bone meal, etc. The production process involves several key machines, including fermenters and reactors for efficient microbial decomposition. Additionally, our filtration systems ensure the removal of impurities, and automatic filling machines streamline the packaging process. Therefore, each organic liquid fertilizer production equipment design is for durability and precision, ensuring commercial production of high-quality liquid organic fertilizers..

Which Industry Can Use Procedure In Preparing Organic Liquid Fertilizer?

To be honest, the application market of liquid organic fertilizer production line is very wide. Also, our liquid fertilizer production process can perform in biogas project, livestock and poultry breeding, paper-making industry, the production of MSG, food processing, pharmaceutical factories, etc. In nature, these customers often have a strict environmental protection system for their own factory. Thus, our production machine help clients in these industries disposing industrial organic waste into liquid fertilizers.

Liquid Fertilizer Production Line

Consequently, many businesses have difficulties in disposing industrial organic waste. Thus, we help them to customize fertilizer production plans. Liquid organic fertilizer production lines can solve the problem of waste disposal and create extra economic benefits, archiving the dual goals of waste resource utilization and environmental protection.

What Raw Materials Can You Use in Liquid Organic Fertilizer Production?

In fact, in addition to the main raw materials, the manufacturing process of liquid organic fertilizers mixes essential auxiliary materials. Also, according to customers’ special production situation, you can add nutrient elements, microbial strains, and functional additives.

Main Raw Materials In Liquid Organic Fertilizer Production

More importantly, the raw materials for liquid water-soluble fertilizer fermentation is water (raw liquid). Additionally, liquid organic fertilizer production process relies primarily on the following raw materials after a certain treatment.

Auxiliary Materials of Liquid Organic Fertilizer Processing

In order to enhance organic liquid fertilizer market competitiveness, you can add some nutrient elements in such an auxiliary material adding pot. For instance, you can add essential macronutrients such as nitrogen, phosphorus, and potassium. Additionally, secondary nutrients include like calcium, magnesium, and sulfur. And micronutrients contain copper, zinc, and iron. If you want to make liquid fertilizer in different formulation, you can add powdered urea, monoammonium phosphate (MAP), potassium nitrate and potassium humate during the manufacturing process. Hence, you need use professional fertilizer production equipment to make them fully mixing.

Typically, the common microbial agents in the fermentation of organic liquid soluble fertilizer are compound bacillus, yeast, lactic acid and other compound enzyme preparations. Moreover, these powder microbial agents are cheap to purchase a lot. For example, you can add bacillus subtilis, bacillus lichen, giant bacillus, gelatinous bacillus or bacillus amyloliquefaciens. As a result, these functional bacterial strains offer the support for the abilities of liquid organic fertilizers to dissolve phosphorus, inhibit soil-borne diseases, increase yield and quality of crops.

Of course, probiotics require protein, energy and trace elements during fermentation and growth of liquid fertilizer manufacturing process. Thus, you can commonly use culture media include molasses, glucose, brown sugar, etc. Furthermore, you’d better to use molasses due to the lowest cost. Generally speaking, each kilogram of strains can ferment 500-1000 kg of liquid fertilizer. And you only need to add 4%-5% molasses for liquid organic fertilizer fermentation.

Functional additives play a critical role in manufacturing liquid organic fertilizers. These additives enhance the effectiveness and stability of the fertilizers, including stable synergists, suspending agents, cosolvent, anti-crystallizing agents, and anti-freezing agents.

Indeed, most customers express their opinion that they want to produce suspended liquid fertilizer. More importantly, using our equipment for suspension fertilizer production has 35-45% nutrient content, which is comparable to common granular compound fertilizers production. Therefore, adopting our technology to generate this type of liquid fertilizers can save transportation costs and facilitate long-distance transportation.

Among them, suspensing agents are the indispensable auxiliary materials for making suspension fertilizer. Typically, they are made from clay substances, such as attagel, sepiolite clay, bentonite, and xanthan gum, which give the liquid a gelatinous texture with high viscosity. Besides, CMC or PAM also has excellent suspension performance and is commonly used in suspended liquid fertilizer production to aid in the uniform dispersion of solid particles. So these allows the insoluble microscopic particles of the raw liquid to remain suspended, preventing sedimentation.

How To Make High-quality Organic Liquid Fertilizer?

If you want to produce high-quality liquid organic fertilizer, the first step is to collect organic raw materials, such as livestock manure and other high moisture organic waste. Secondly, you should carry out pre-treatment, including solid-liquid separation, crushing, and mixing, followed by filtering and disinfecting these liquids. Then, through anaerobic or aerobic fermentation, organic matter can be decomposed into nutrient rich liquid fertilizers under the action of microorganisms. Finally, after certain blending and packaging, you will get the finished organic liquid fertilizer. Besides, the entire manufacturing process requires strict control of temperature, humidity, and pH values to ensure product quality and fertilizer efficiency. Thus, here are complete liquid organic water-soluble fertilizer manufacturing steps.

To learn more about the complex process of manufacturing high-quality liquid organic fertilizer, we invite you to contact us. Also, our experts are ready to provide information of liquid organic fertilizer equipment in detail and answer any questions you may have.

What Equipment Does The Initial Liquid Organic Fertilizer Production Preparation Include?

The initial treatment equipment of organic liquid fertilizer includes two main parts: dehydration of high moisture organic waste and liquid-liquid separation. First, you need appropriate dewatering equipment to get large amount of organic wastewater. Next, you may use liquid-liquid separation technology to obtain high concentration organic fertilizer liquid. Accordingly, you can choose to construct sedimentation tank for organic liquid fermentation and storage briefly.

Equipment for Obtaining Raw Liquid in Liquid Organic Fertilizer Production

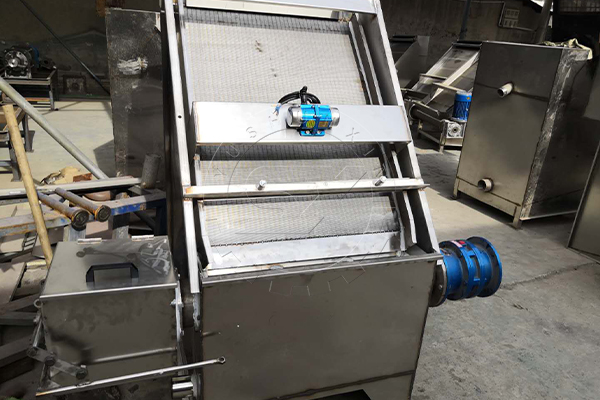

Inclined Manure Solid-liquid Separation Machine For >85% Moisture Dewatering

If you are looking for a dehydrator for an organic fertilizer production plant, you can definitely consider our company. We have rich production experience in the production of fertilizer dewatering equipment. Among them, our inclined solid-liquid separator is a small machine for handling organic waste with high water content (>85%). This machine covers only 3-6㎡. Obviously, it is suitable for material pretreatment in small organic liquid fertilizer plants. In general, the minimum scale SXTSX-800 can process 20-25m³/h of cow manure, pig manure or sludge; 10-15m³/h of chicken manure or traditional Chinese medicine residues; 15-20m³/h of distillers’ grains, etc. In addition, our factory can customize the specifications of the filter screen according to the material requirements of customers. Secondly, the whole machine is made of 304 stainless steel material, which meets the needs of liquid and viscous feces treatment.

Stacked Screw Press Dewatering Machine for Sludge Thickening & Dewatering

Recently, our company has developed a new type of solid-liquid separation equipment that utilizes screw extrusion dehydration. It is suitable for high and low concentration sludge in industries such as municipal sewage, food, chemical, metallurgy, mine processing, papermaking, printing and dyeing, pharmaceuticals, etc. If you want to process low concentration (2000mg/L) sludge for liquid organic fertilizer manufacturing, there is no need to build a storage tank, which reduces construction costs. Moreover, this dewatering device has compact structure, including an electrical control cabinet, a metering tank, a flocculation mixing tank, and a main body. Also, it has small footprint, light weight, and is easy to transport and maintain. The speed of the spiral shaft is about 2-3r/min, with low electrical consumption. Besides, the body is almost entirely made of stainless steel material, which make the service life more than 2 times of similar products. In order to achieve 24-hour continuous unmanned operation, we choose high-performance motors with a protection level of IP54 and an insulation level of F.

Extraction And Stripping Apparatus for Liquid-liquid Separation

Furthermore, our company has promoted a new and efficient liquid-liquid extraction and separation equipment. This device utilizes the centrifugal force generated by high-speed rotation to efficiently separate liquid components with different densities. In the liquid organic fertilizer production process, centrifugal extraction machine can effectively separate organic substances and impurities, concentrate useful components, remove excess solvents and water, and meet the preparation requirements of high concentration liquid organic fertilizers. In addition, it is suitable for the extraction of lactic acid fermentation solution and industrial wastewater treatment. Compared with traditional separation methods, it can complete the separation and purification process in a shorter time, reducing production costs. Typically, the selectable materials for equipment include 304, 316L stainless steel, composite materials, or fluorine materials. Also, the wastewater treatment capacity is 15-150m³/h, the power is 4-11kw, and the weight is 860-2500kg.

Sedimentation Tank Construction For Organic Liquid Fertilizer Production

The construction of sedimentation tank of organic liquid fertilizers production includes anaerobic fermentation, aggregate, and storage tanks. You can design its size and configuration according to specific process requirements and production scale. Firstly, the anaerobic fermentation process requires the sealing and structural strength. So it is necessary to use high-quality cement materials to ensure no leakage or cracks of sedimentation tank. Secondly, the aggregate pool can collect 10% organic sediments. Also, this part requires a drainage and sedimentation system to ensure sufficient separation of solids and liquids. Finally, the storage pool can temporarily store the liquid, ready for the next step of liquid fertilizer production.

In order to better serve our customers, we can provide detailed construction drawings for free. This will include information on the overall layout, specific dimensions, material selection, and other aspects of the sedimentation tank. If necessary, we can also dispatch a professional team to conduct on-site inspections and measurements to ensure that the design and construction of the sedimentation tank fully meet the site conditions and specific needs of the clients.

Water Treatment Equipment For Handling Organic Fertilizer Liquid

The initial treatment equipment of organic liquid fertilizer includes two main parts: dehydration of high moisture organic waste and liquid-liquid separation. First, you need appropriate dewatering equipment to get large amount of organic wastewater. Next, you may use liquid-liquid separation technology to obtain high concentration organic fertilizer liquid. Accordingly, you can choose to construct sedimentation tank for organic liquid fermentation and storage briefly.

Organic Liquid Filtration Device for Fertilizer Production

Dual Filter System with The Fineness of 38-250μm

The dual filter consists of two single bag filters and a three-way ball valve, with the simple structure and straightforward operation. Also, it is of used in the pre-treatment of wastewater filtration. Because of two independent alternative filtering units, it can run liquid organic manufacturing process continuously for 24 hours. In a word, as the cleanness and component replacement of one filtration unit, another can continue to work.

Furthermore, you need to install such a duplex filter at every step of liquid organic fertilizer production to improve the quality of the finished liquid fertilizer. Moreover, you can set up a two-stage filtration system. With the first filtration unit removing medium-sized particles and impurities, the second unit eliminates finer substances. Additionally, it has CIP cleaning function for keep filter performance.

In addition, we may customize filter materials based on customer requirements – carbon steel, 304, 316 stainless steel. Also, we have a mirror finish or matte finish for the surface of this filtering machine. The screen hole diameter of double filter is about 60-400 mesh. Besides, its working pressure is less than 0.2MPa. And the filtering capacity is 5-10t/h.

UV Water Sterilizer for Post-treatment of Organic Liquid Filtration

In fact, the filtered organic liquid fertilizer may require further post-treatment, such as UV disinfection or microfiltration. So, we will basically equip the dual filter with a UV sterilizer at the same time. Both the inside and outside of the main body are made of 304 or 316 stainless steel, and we do polishing to improve ultraviolet radiation. Also, it suitable for various water treatment projects, including sewage treatment engineering, drinking water disinfection, and more. Its purpose is to kill bacteria, viruses, yeast, mold, algae and degrade chloride in water. The ultraviolet sterilization band is mainly between 200-300nm, with the strongest sterilization ability at a wavelength of 253.7 nm. Thus, you can adjust it through the control cabinet. In general, we guarantee our product quality, and we use PHILIPS brand UV lamp tubes with an effective service life of up to 12,000 hours. Also, we offer a 10-year guarantee on the stainless steel shell and a 1-year guarantee on other accessories.

Water Purification System in Organic Liquid Manufacturing Process

Dual Filter System with The Fineness of 38-250μm

RO water system is a high-quality water purification equipment. After microfiltration, adsorption, reverse osmosis, the pump pressurizes the raw liquid. Then, it can directly convert tap water into high-purity water. Generally speaking, raw water includes municipal tap water, non polluting groundwater or surface water and lake water. Moreover, the reason why use reverse osmosis equipment in the production process of liquid fertilizer is to remove impurities, heavy metals, salts, and other pollutants from water. This is crucial because water quality directly affects the quality and effectiveness of organic liquid fertilizers. Otherwise, polluted or excessively hard water may affect its nutrients’ solubility and stability.

Certainly, water treatment machine is always a little expensive. For low budget and small liquid organic fertilizer factories, you can buy this to produce 1-50m³/h pure water. In particular, this equipment uses high-end reverse osmosis membranes, with a desalination rate of up to 98-99%. Simultaneously, it is equipped with activated carbon or quartz sand filters, effectively removing soluble salts, TOC, and SiO2. Moreover, the inlet water pressure is about 0.2-0.5MPa and the single equipment’s power of 2.25kw. Moreover, the reverse osmosis recovery rate is 60-75% for primary RO water system and 80-85% for secondary part. Also, the source water hardness is about <10mmol/L, and the outlet water hardness is ≤0.03mmol/L.

Large Scale Integrated Ultrafiltration System for Processing 10,000-1,000,000 LPH Organic Liquid

In addition, for large-scale organic liquid fertilizer manufacturers, we recommend using ultrafiltration membrane components. Because it can form an integrated water treatment system with the capacity of 10-100t/h. And if you have sufficient funds, it can reach 200 t/h of water treatment efficiency. Moreover, this device is made of polyvinylidene fluoride (PVDF), which has excellent chemical stability and mechanical strength. Besides, the membrane pore size is 0.03 μ m-1nm, which can remove 100% impurities such as suspended particles, colloids, chromaticity, turbidity, organic chemicals, bacteria, and Escherichia coli with the size greater than 2um. Also, the shell material of this large commercial ultrafiltration system is UPVC, which has brilliant corrosion resistance. Hence, you can use our liquid fertilizer equipment to treat the organic waste liquid with a ≤0.2 NTU turbidity and ≤3.0 SDI. Furthermore, we ensure that the filtered liquid fertilizer is clear and pure. And the service life of the components is up to 5 years.

In summary, the application of ultrafiltration membrane components in the production of organic liquid fertilizers not only ensures high purity and stability of the products, but also significantly improves production efficiency and economic benefits.

High–quality Pump & Flowmeter In Liquid Organic Fertilizer Manufacturing Process

Corrosion resistant pumps and flow meters are essential auxiliary equipment in the production process of organic liquid fertilizers. For one thing, the water pumps can transport corrosive organic fertilizer liquids. Usually, they are made of anti-corrosive materials such as stainless steel, alloys, or special plastics. Thus, it can effectively prevent the corrosion of the pump body by acidic and alkaline liquids. So it can still maintain good working conditions, extending the lifespan of the entire organic liquid fertilizer production line.

For another thing, flow meters commonly include electromagnetic flowmeters, ultrasonic flowmeters, and turbine flowmeters. Typically, they have functions of real-time monitoring and measurement of the flow rate of liquid fertilizers through automatic control systems. Then, you can achieve precise adjustment during the liquid fertilizer production process. Its design requires high precision and corrosion resistance, improving production efficiency and product quality.

How to Make And Store Organic Liquid Fertilizer?

Which equipment are key to produce and store organic liquid fertilizers? In fact, fermentation tanks and reactors form the core of liquid organic fertilizer production. Additionally, the liquid organic fertilizer plant can apply other advanced technology and equipment. For example, using auxiliary material addition pot, CIP cleaning system, finished product tanks can ensure high-quality output and safe preservation for liquid organic fertilizer manufacturing.

SUS 304 Stainless Steel Tanks

The liquid organic fertilizer production process relies on many liquid tanks like fermentation and reaction tanks. Generally speaking, these liquid pots have similar appearance and functions. So, our company design organic liquid fertilizer pots (5m³-50m³). Also, the tanks use high-quality stainless steel such as SUS304 and SUS316, and they resist corrosion well. They have insulation layers and heating, cooling, mixing functions. These liquid tanks use mirror-polished outer wall and fully enclosed design to prevent contamination in liquid fertilizer fermentation process. To save energy, we offer various heating options, such as steam, electric, or thermal oil heating, while cooling methods like coil or spray water cooling.

Moreover, you need another small liquid tank for adding NPK powder or microbial agents. We understand that different raw materials may require unique settings for fermentation. Therefore, the equipment in our liquid fertilizer production line is customizable. According to different production needs, you also may require enzymatic tanks or emulsification tanks. Their structures are similar, each with its own characteristics in terms of usage and detailed design. Indeed, this liquid pots are made from stainless stain, with insulation layers and stirring devices. Actually, you can adjust the motor speeds to achieve specific organic liquid fertilizer fermentation effects and consistence.

Automatic CIP Cleaning System

CIP systems streamline hygiene in liquid organic fertilizer production equipment. Typically, it consists of two to three liquid tanks. The cleaning steps include water, alkaline solution, hot water, acid, and pure water at room temperature. What’s more, we design this system with stainless steel frames and steam heating to save energy consumption. The CIP system utilizes a conveying and recycling pump to circulate the cleaning solution within the containers, guaranteeing liquid fertilizer equipment thorough cleaning. Besides, clients may choose semi- or fully-automatic systems based on budget, ensuring compliance with strict sanitation standards for organic liquid fertilizer manufacturing process. Additionally, the system includes temperature sensors, liquid level controls, and overflow protection to prevent residue buildup.

Storage Solution for Organic Liquid Fertilizer

Storing pot in the liquid organic fertilizer production plant can maintain liquid fertilizer quality. Typically, we are available in designing both vertical and horizontal storage tanks without motors and heating devices. Most customers choose stainless steel liquid storing pots for corrosion resistance and ease of cleaning. So the storage pots in our organic liquid fertilizer production equipment are designed for long-term use. Certainly, we provide a cost-effective alternative – fiberglass storage tanks. Because the liquid fertilizer tank is made of fiberglass, which is lighter in weight, easier to install and transport, and has a lower cost than stainless steel. However, for customers with a tighter budget, you can directly store fertilizer liquid in plastic containers. But it is only suitable for short-term use.

Efficient Packaging Solutions for Organic Liquid Fertilizer Filling

When establishing a liquid organic fertilizer production plant, we offer a range of filling solutions. Particularly, we have high-quality liquid fertilizer packaging equipment including large bucket filling line, small bottle filling line, capping machine, labeling machine, etc. Thus, efficient, automated packing machines maintain liquid fertilizer quality during the organic liquid fertilizer production process and are ready for market distribution.

Large Bucket Filling Line for Bulk Liquid Organic Fertilizer Production

For one thing, we design the large bucket filling line to handle 5L-200L barrels for mass production of bulk organic liquid fertilizers. Usually, its accuracy is within ±0.1% to ±5ml. Moreover, the large bucket liquid fertilizer filling line contains filling, positioning, weighing, unloading, capping, coding, and conveying processes. The system features a PLC control system, making it easy to adjust parameters via a touch screen. Furthermore, the equipment uses a pressurized weighing system that overcomes the challenges of filling thick or viscous liquids. In addition, the liquid fertilizer filling line uses photoelectric sensors to ensure that each barrel is filled. Besides, this line is built with corrosion-resistant 304 stainless steel, making it ideal for ensuring durability in acidic/alkaline environments. So it is widely used in industries like fertilizers, chemicals, food, and pharmaceuticals.

Small-Scale Organic Liquid Fertilizer Packing with Compact Bottles

For another thing, the capacity range of the small bottle filling line is usually between 50ml-5L. Most customers choose this packing method for filling in liquid fertilizer bottles ranging from 250ml-2L, suitable for retail. Additionally, it consists of three main machines: the servo quantitative filling machine, capping machine, and labeling machine. Each of these machines brings unique benefits to your organic liquid fertilizer production.

Get Free Quote Now!