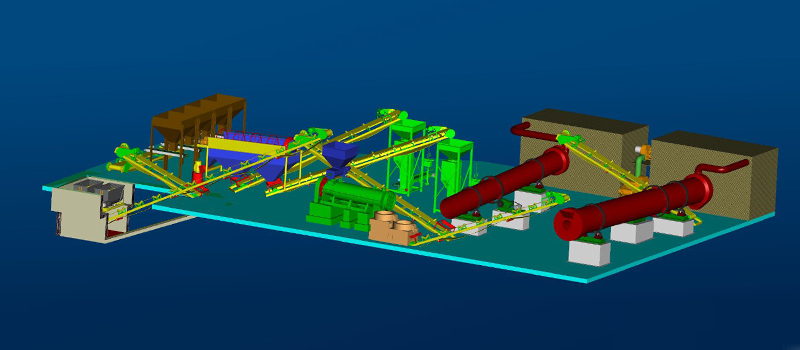

NPK Fertilizer Production Line

Shunxin is a professional manufacturer for NPK fertilizer production equipment. Our designed NPK fertilizer production line consists of a series of advanced equipment which has the characteristics of low production cost and high production efficiency. The production line can be used for granulation of various raw materials with NPK elements.

We provide our respected customers with complete equipment and solutions for NPK fertilizer production!

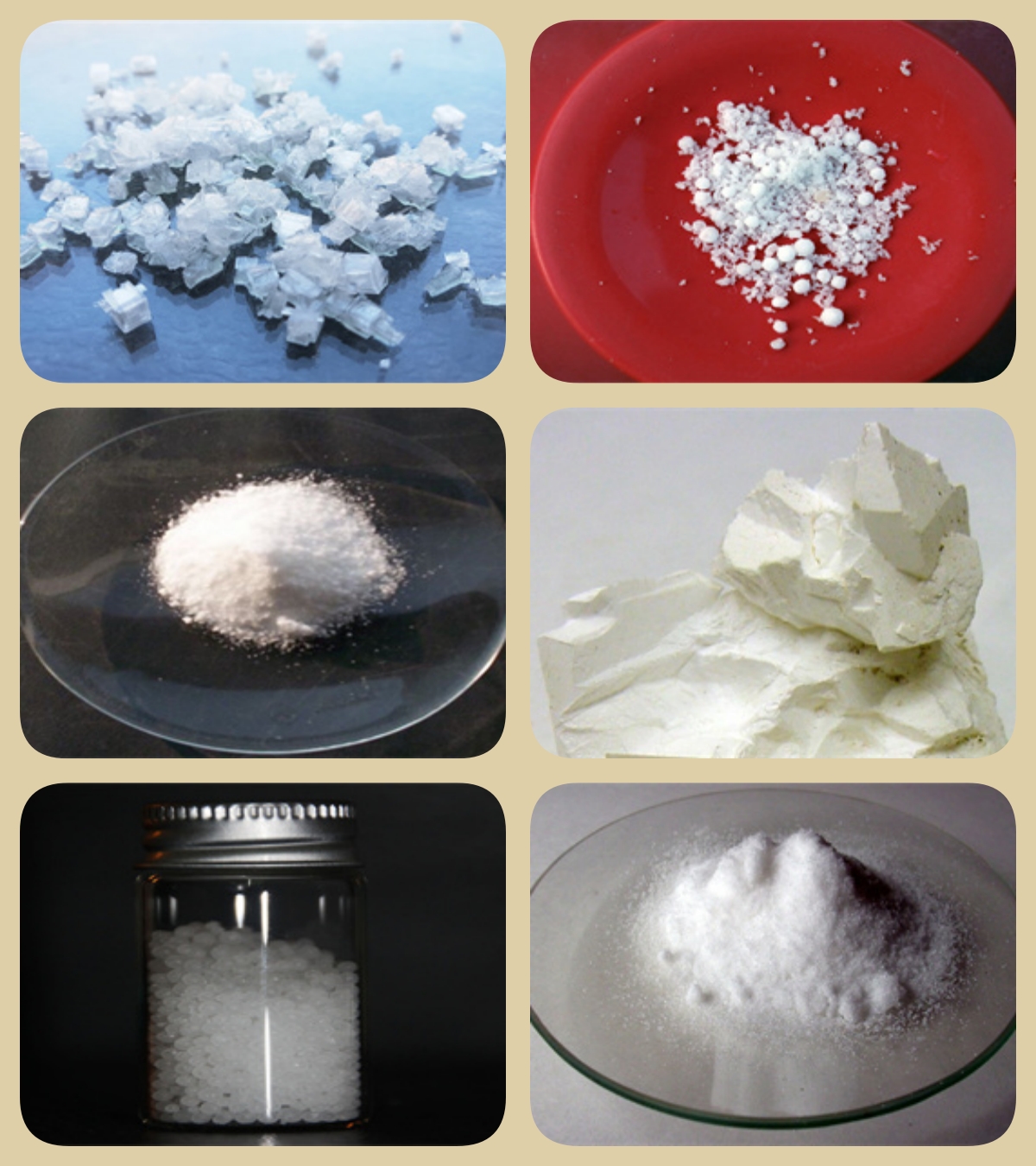

What Materials Can Use in NPK Fertilizer Production?

Raw materials for compound fertilizer production are mainly divided into three categories, including some fillers like clay.

- Nitrogen fertilizers: ammonium chloride, ammonium sulfate, urea, calcium nitrate, etc.

- Potassium fertilizers: potassium chloride, potassium sulfate, plant ash, etc.

- Potassium fertilizers: (heavy) calcium superphosphate, calcium-magnesium phosphate, phosphorite powder, etc.

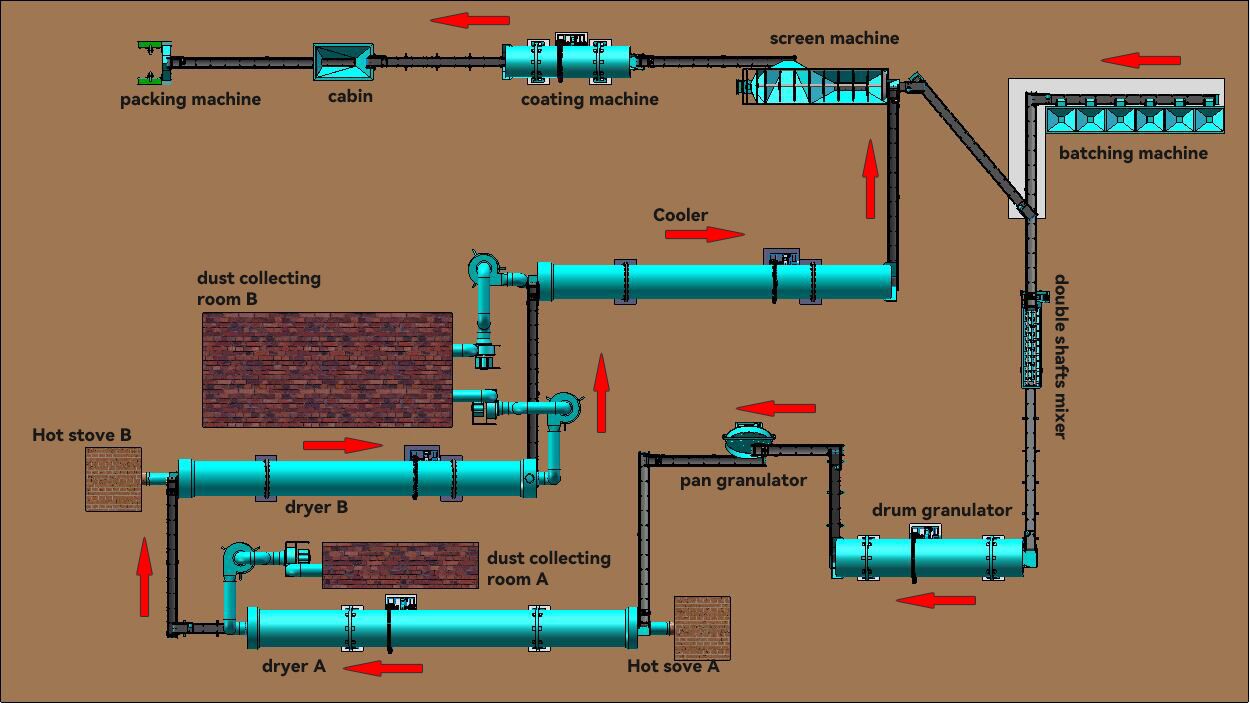

Suitable for NPK Fertilizer Production Equipment

1. Batching Machine

Dynamic automatic batching machine is appropriate for the sites of continuous batching. It has characteristics of high batching efficiency, short operating time, improving operating conditions, and contributing to the promotion of industrial production automation. Static batching machine is suitable for the sites of quantitative batching with higher batching precision.

2. Vertical Chain Crusher

Vertical chain crusher can be widely used for crush various materials such as limestone, cement clinker, gypsum, slag, copper ore, iron ore and so on. And it is also one of the crushing equipment commonly occurs in NPK fertilizer industry.

3. Horizontal Mixer

Horizontal mixer is a generic mixing machine. It widely occurs in chemical industry, pharmaceutic industry, food processing plant, architectural material industry and other fields.

4. Rotary Drum Granulator

Rotary drum granulator is a molding machine that can make material to a specific shape. It is also one of the key equipment in compound fertilizer industry. This machine has good appearance quality, corrosion and wear resistance, low energy consumption, long service life, simple operation and maintenance, etc.

5. Rotary Drum Drying And Cooling Machine

In the drying process, you need to reduce the moisture of the granulated particles, making the particles harder and easier to store. After drying, the particles have a higher temperature and you require cooling before packaging.

6. Rotary Screening Machine

The rotary screening machine is a new type of self-cleaning screen special equipment, and has characteristics of high screening effeciency, low noise, small amount of dust, long service life, and convenient maintenance.

7. Conveying Equipment

The conveying equipment plays an vital role in the NPK fertilizer production process as it connects the different parts of the entire production line. In this NPK fertilizer production line, we have chosen to provide you with mobile belt conveyor. This is because it has stronger conveying ability than other types of conveyors, which will make your production process more efficient and economical.

Get Free Quote Now!