NPK Fetilizer Plant Cost

Generally speaking, NPK fertilizer plant cost ranges from $30,000 to $1,200,000 for purchasing 1-40 t/h compound fertilizer equipment. Besides, the NPK fertilizer production project cost serves as the foundation. By considering factors such as raw materials, land, equipment configuration, construction cost, operation costs, and labor expenses, one can easily calculate the total cost of setting up an NPK fertilizer factory. Yushunxin has been offering NPK fertilizer manufacturing plants comprehensive solutions to complete their production process. Moreover, we are ready to fulfill your demands at every stage of your NPK fertilizer plant project and ensure its successful completion. Whether you require assistance with batching, crushing, mixing, granulation, packing, or palletizing, we provide support.

Generally speaking, NPK fertilizer plant cost ranges from $30,000 to $1,200,000 for purchasing 1-40 t/h compound fertilizer equipment. Besides, the NPK fertilizer production project cost serves as the foundation. By considering factors such as raw materials, land, equipment configuration, construction cost, operation costs, and labor expenses, one can easily calculate the total cost of setting up an NPK fertilizer factory. Yushunxin has been offering NPK fertilizer manufacturing plants comprehensive solutions to complete their production process. Moreover, we are ready to fulfill your demands at every stage of your NPK fertilizer plant project and ensure its successful completion. Whether you require assistance with batching, crushing, mixing, granulation, packing, or palletizing, we provide support.

Top 2 Techniques You Can Use to Reduce NPK Fertilizer Plant Cost

ypically, NPK fertilizer granule production utilizes two primary techniques: dry granulation and wet granulation. In general, the cost of establishing a compound fertilizer plant varies depending on output and scale. However, establishing an NPK fertilizer production system using dry granulation requires a lower initial investment than wet granulation. Therefore, investors need to contact professional fertilizer machinery manufacturers like us for the final process plan and equipment configuration.

How Much Does A 1-30 T/H NPK Ferilizer Dry Granulation Plant Cost?

etting up a dry granulation plant for NPK fertilizer production can be cost-effective due to the elimination of drying processes. In a word, npk dry granulation primarily utilizes double roller granulators without dryer, cooler, hot air blast, etc, which significantly reduces initial equipment investment. Furthermore, we offer 6 conventional NPK fertilizer extrusion granulation line costs with capacities ranging from 1-30 t/h of NPK fertilizer granules. Consequently, the cost to buy such a compound fertilizer dry granulation line is approx. 30,000 to 460,000 USD.

The following are the NPK fertilizer manufacturing plant costs with different outputs. And they are only for the complete set of NPK dry granulation process, excluding construction and other prices.

Project Proposals on 1-40 T/H NPK Wet Granulation Plant Setup Cost

Wet granulation, using disk granulator and rotary drum granulator, produces much more compound fertilizer granules than dry granulation. Moreover, we offer 6 standard wet granulation lines to make 1-40 t/h NPK fertilizer granules. Therefore, the NPK granular fertilizer plant setup cost ranges from $100,000 to 1.2 million USD for entire production line investment.

In addition, for small-scale outputs, a single wet granulator suffices. However, for larger scale NPK fertilizer manufacturing, we typically suggesting combining one rotary drum granulator with multiple pan granulators. So it will enhance granulation rate and roundness of particles. Furthermore, if you need to produce exceeding 10 t/h compound fertilizer pellets, you require two dryers to effectively manage moisture content and ensure ideal granule formation.

Here are npk fertilizer pellet plant cost lists with wet granulation.

What Equipment You Can Choose to Build An NPK Fertilizer Factory?

he equipment price is the primary component of 1-40 t/h NPK wet granulation plant layout cost. Therefore, our company can design a full set of processing equipment for NPK fertilizer plants, like batching, crushing, mixing, granulation, packing, or palletizing machines.

The following are the prices and parameters of the main equipment required for the 1-40 t/h compound fertilizer plant:

Cost of NPK Fertilizer Granulators in Compound Fertilizer Plant

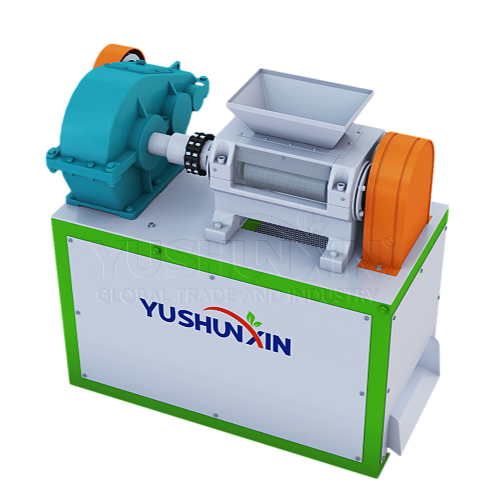

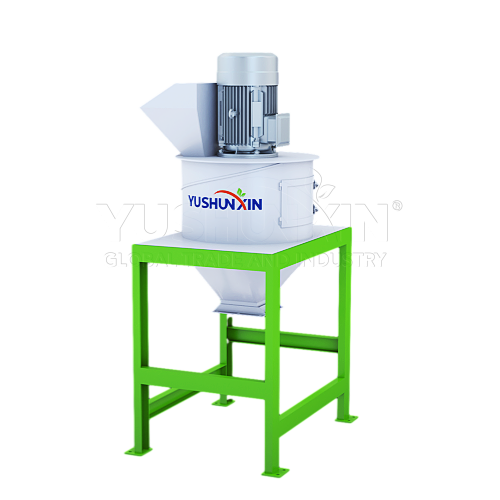

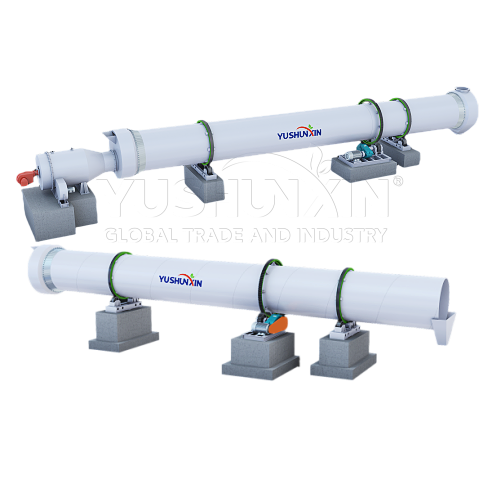

There are 3 types of granulation machine in NPK fertilizer production. For small scale compound fertilizer manufacturing line (1-2T/H), double roller pelletizer is suitable. Meanwhile, medium NPK fertilizer production systems employ disc granulators. Finally, for large-scale fertilizer factories, rotary drum granulator produces up to 30 t/h of NPK fertilizer granules.

$2,600-5,400 USD

$6,000-42,000 USD

$2,000-10,000 USD

Auxiliary Equipment Price Lists of NPK Fertilizer Factory

Our company provides comprehensive price lists for auxiliary equipment to make NPK granules. We offer batching machines, crushers, dryers, screening machines, mixers, packing machines, and more. Moreover, we can customize different quantities and models according to customer needs. Therefore, we offer flexible solutions to meet diverse customer requirements.

$3,750-4,200 / Bin

$1,250-7,500

$2,000-3,000

$5,000-75,000

$1,800-11,000

$4,000-10,000

Therefore, equipment price is the key factor when building an NPK fertilizer factory. Our company provides complete compound fertilizer processing equipment, including suitable granulation machines for any scale, and auxiliary equipment like batching, crushing, and packing machines. Moreover, you can contact us for customizable NPK fertilizer pellet making solutions.

What Is The Land Cost for Establishing An NPK Fertilizer Pellet Factory?

he first step in establishing a NPK fertilizer factory is to acquire land. And land cost includes the purchase price or rental fees. How to calculate the cost of land? An NPK fertilizer factory includes production workshops, warehouses, office areas, etc. Additionally, these costs vary due to factors such as region, country, and city development level. Generally, monthly land leasing averages between $5–30 per square meter. Conversely, purchasing land is significantly more expensive, ranging from $100–500 per square meter. Therefore, NPK fertilizer producers with low budgets may opt to rent land. In contrast, large compound fertilizer manufacturers might invest in purchasing land locally or build fertilizer factories in countries with lower rents, like those in Africa.

Land Cost of NPK Dry Granulation Plant Layout

Land cost is a significant factor in planning an NPK wet granulation plant.

- Small-scale plants (1–8 tons/hour) need 1,200–2,000 ㎡, leasing at $6,000–$60,000 monthly or purchasing for $120,000–$1,000,000.

- Medium-scale plants (10–15 tons/hour) require 2,400–3,600 ㎡, with leasing costs of $12,000–$108,000 monthly and purchasing costs of $240,000–$1,800,000.

- Large-scale plants (20–40 tons/hour) occupy 4,000–8,000 ㎡, leasing at $20,000–$240,000 monthly or purchasing for $400,000–$4,000,000.

Thus, understanding land costs is essential.

In conclusion, establishing an NPK fertilizer plant involves various costs influenced by multiple factors. Investors should consider production techniques, equipment configuration, output scale, and land acquisition. For instance, choosing dry granulation can lower the initial investment since it eliminates drying processes. Equipment costs vary with production capacity. They range from approximately $30,000 for small-scale dry granulation lines to over $1 million for large-scale wet granulation plants. Moreover, land costs significantly impact the total investment and depend on the location and whether the land is rented or purchased. Therefore, a thorough evaluation of these factors is crucial for planning and successfully establishing an efficient and cost-effective NPK fertilizer production facility.

In conclusion, establishing an NPK fertilizer plant involves various costs influenced by multiple factors. Investors should consider production techniques, equipment configuration, output scale, and land acquisition. For instance, choosing dry granulation can lower the initial investment since it eliminates drying processes. Equipment costs vary with production capacity. They range from approximately $30,000 for small-scale dry granulation lines to over $1 million for large-scale wet granulation plants. Moreover, land costs significantly impact the total investment and depend on the location and whether the land is rented or purchased. Therefore, a thorough evaluation of these factors is crucial for planning and successfully establishing an efficient and cost-effective NPK fertilizer production facility.

Get Free Quote Now!