Organic Fertilizer Production Line

The most favored and Most selling Organic Fertilizer Production Line!

The organic fertilizer production line is to ferment and process organic waste as raw materials like livestock manure and kitchen waste for manufacturing organic fertilizer by using a set of production equipment. It not only creates economic benefits for fertilizer businesses, but also makes great contributions to ecological and environmental improvements.

Organic fertilizer production line is divided into powder and granular organic fertilizer production lines according to the processing techniques.

The important thing is that you can customize any equipment according to your factory condition, raw materials and budget. No matter what kind of organic fertilizer you want to process, whether powder or granular, Shunxin always has the equipment you need!

What Is The Production Process

Organic fertilizer production process are briefly as follows: Composting & Fermentation → Crushing → Mixing → (Granulating → ) Drying → Cooling → Screening → Packing.

Main Equipment of Organic Fertilizer Production Line

The organic fertilizer production line is mainly divided into the pre-treatment part and the granulation part.

- Pre-treatment part is also called powder organic fertilizer manufacturing equipment, which includes dewatering machine, fermentation compost machine, crusher, rotary screening machine, etc.

- Granulation part contains mixer, organic fertilizer granulator, rotary drum drying and cooling machines, rotary screening machine, rotary coating machine, and automatic quantitative packing scale.

1. Solid-liquid Separator Machine

It is a sort of dehydrating equipment that can separate pig, horse, cow, and chicken dung into liquid and solid organic fertilizer. We have two models, SXTS-180 and SXTS-230, with the output of 10-20m³/h. The machines have the characteristics of high automation level, simple operation, easy installation and maintenance, low power consumption, large daily processing capacity, and no need for additives. The stainless steel structure provides excellent strength, wear resistance, durability, corrosion resistance, and a long service life.

2. Organic Fertilizer Fermentation Pot

You can use the fermentation pot to treat organic waste such as manure of animal manure, mushroom residue, drug residue, crop straw, etc. It takes only 10 hours to finish the harmless treatment process while occupying less land, emitting no pollution, and thoroughly destroying pest eggs, so it is the best choice to realize waste resource utilization for the majority of breeding enterprises, recycling and ecological agriculture. We can make horizontal or vertical fermentation compost machine with different capacities ranging from 5-150m³based on the needs of the customers.

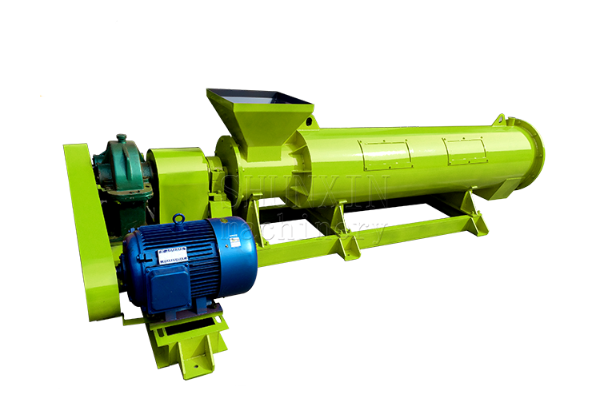

3. Semi-wet Material Crusher

Semi-wet material crusher is a professional crushing equipment for high humidity and fibrous materials. We have four models, SXSF-40, SXSF-60, SXSF-90 and SXSF-120, with the output of 1-8t/h. Semi-wet material crusher is commonly used in small organic fertilizer production and processing, with excellent results when extensively used in bio-organic fermentation composting, composting of municipal solid waste, grass sludge carbon, rural straw waste, industrial organic waste, livestock manure, and other specific equipment for the materials crushing process of composting.

4. New Type Organic Fertilizer Granulator

This new type organic fertilizer granulator is capable of granulating a wide range of organic materials, particularly light granule powder materials. The majority of consumers chose as the optimal product because of the high pelletizing rate, smooth operation, robust and durable equipment, and long service life. This machine is suitable for granulating organic fertilizer directly after fermentation, eliminating the drying process and greatly reducing the cost. Our factory can produce and build various specifications of new type organic fertilizer granulators according to the requirements of users.

5. Rotary Screening Machine

The rotary screening machine commonly occurs in the production of organic fertilizer and compound fertilizer. Its usage purpose is mainly for the separation of finished products and return materials. It can achieve the classification of finished products, making granules more uniform. It is a new type of self-cleaning screen special equipment, and has characteristics of high screening effeciency, low noise, small amount of dust, long service life, less and convenient maintenance, and its screening capacity is 1-20t/h.

6. Automatic Quantitative Packing Scale

We design the automatic quantitative packing scale for quantitative packing, which contains double and single bucket packing scale. It adopts the integrated structure, and has the characteristics of low scale height, compact structure, efficient, novel appearance, easy installation and convenient maintenance. The quantitative of the system is 2%.

Get Free Quote Now!