Organic Fertilizer Production Plant Cost

Some fertilizer businesses and investors planning to establish a organic fertilizer factory should pay particular attention to understanding the cost factors. Moreover, the organic fertilizer production plant cost include land rent, plant construction, fertilizer production equipment, costs of raw and auxiliary materials, labor, energy consumption, return on investment, and more. Depending on the type of raw materials and the desired output, we can provide customized solutions for the production of organic fertilizer powder or granules. All in all, these flexible organic fertilizer manufacturing plans cater to clients with equipment budgets ranging from $10,000 to $550,000.

Some fertilizer businesses and investors planning to set up a organic fertilizer plant should pay particular attention to understanding the fertilizer production plant cost. Moreover, the expenses involved in establishing such a organic fertilizer factory include land rent, plant construction, fertilizer production equipment, costs of raw and auxiliary materials, labor, energy consumption, return on investment, and more. Depending on the type of raw materials and the desired output, we can provide customized solutions for the production of organic fertilizer powder or granules or liquid fertilizer. All in all, these fertilzizer manufacturing plans cater to clients with equipment budgets ranging from $30,000 to $550,000.

How Much Cost to Builld A Organic Fertilizer Production Factory?

The cost to build an organic fertilizer factory is based on the budget and production scale (1-20 t/h). Generally speaking, organic fertilizer powder production line require less equipment and investment compared to granular ones, which costs about $10,000–$100,000. Also, the total cost for organic fertilizer pellet manufacturing equipment range from $110,000–$550,000. Furthermore, we can design provide free design of organic fertilizer plant drawings for clients.

Top 4 Powder Organic Fertilizer Production Projects

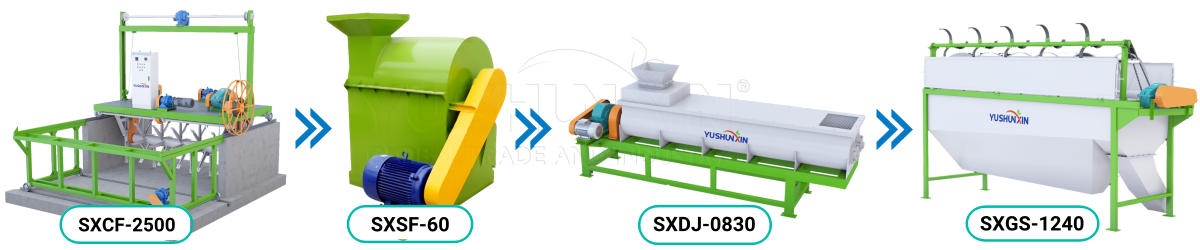

We offer 4 main 1-20 t/h powder organic fertilizer production plans with a budget under $100,000. For low cost organic fertilizer machines, you can optional buy important equipment like dehydrator, composter, and crusher. Additionally, the complete organic fertilizer powdery manufacturing system needs loading to packing, ensuring efficient powdered fertilizer production process.

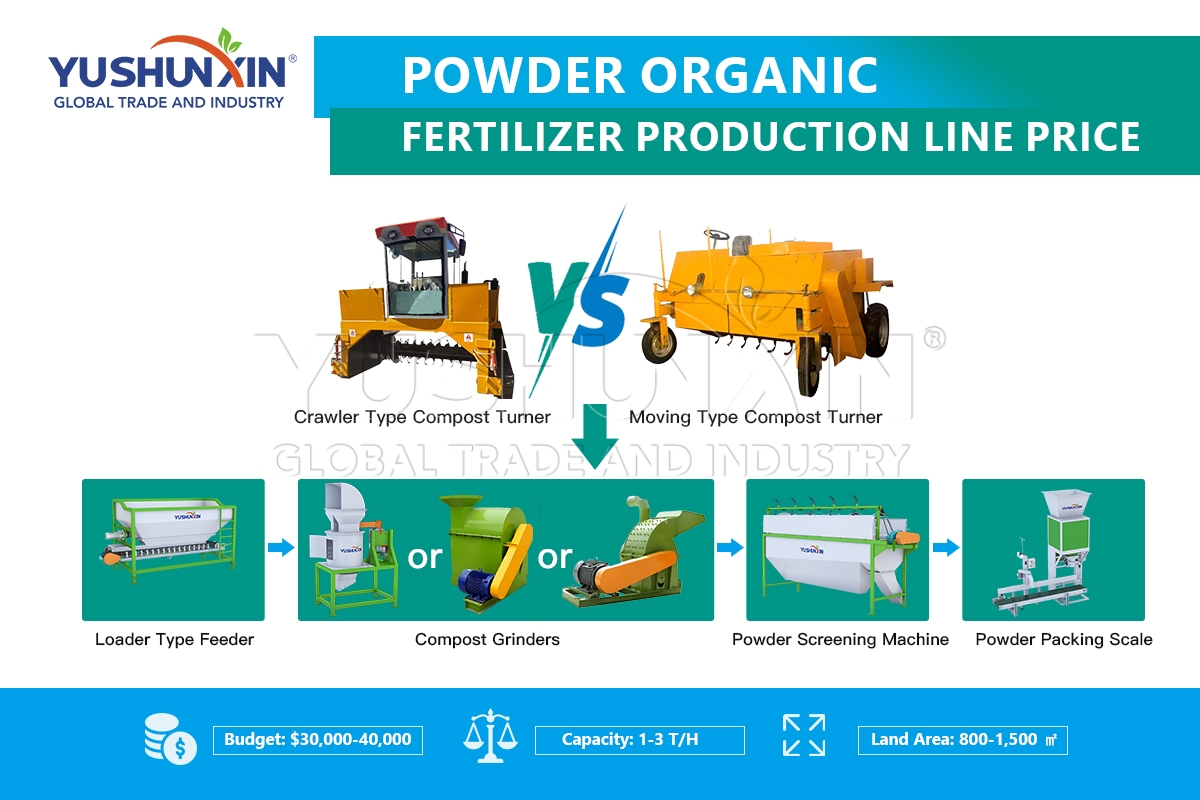

The Simplest Small Organic Fertilizer Powder System Price

$30,000-40,000 Powder Organic Fertilizer Production Line

If you have money between $30,000 and $45,000, you can choose 1-3 t/h powdery organic fertilizer production line. Moreover, it covers an area of around 800-1,500㎡, of which the fermentation area accounts for about 200-500 ㎡.

- Primarily, you should invest in fermentation compost equipment, such as SXXFD-2500 moving type compost machine with capacity of 600-800 m³/h, at $6,000-7,500 USD. And it can work in the open air.

- Additionally, you can purchase a SXFLF-600 vertical crusher available with capacity of 3-5 t/h, at $2,000-2,500 USD. Also, it’s not easy to block while crushing high moisture materials.

- Furthermore, you can select a SXGS-1240 rotary screening machine (3-5 t/h) for selecting powder compost materials, at $1,800-2,000 USD; A SXFM-2030 loader type feeder for organic waste feeding, at $3,800-4,000 USD; a SXWJ-9015 horizontal mixer (3-5 t/h) for uniform compost blending, at $1,700-1,950 USD; And an automatic powder packing scale ($4,200-4,600 USD) for organic fertilizer powder packaging.

How to Start A Granular Organic Fertilizer Plant with $110,000-$550,000 for Investment?

How to Start A Granular Organic Fertilizer Plant with $110,000 – $550,000 for Investment?

How to Invest A Granular Organic Fertilizer Plant with $110,000-$550,000?

If you have enough funds and want to make more market competitive finished organic fertilizers for export, you can choose the pellet organic production line. Because it makes organic fertilizer granules with more beautiful appearance, uniform size, longer shelf life, and easier transportation. In addition, we have 3 kinds of organic particle fertilizer production plans for different fertilizer manufacturers within the budget of 110,000-550,000 dollars. Therefore, there are various units you can select: loader type feeder, compost machine (7 Types), compost crusher (3 Types), rotary screening machine (optional models), horizontal mixer (optional models), organic fertilizer wet granulator (3 Types), dryer & cooler (optional models), organic fertilizer polishing machine (optional), rotary coating machine (optional), and packing machines.

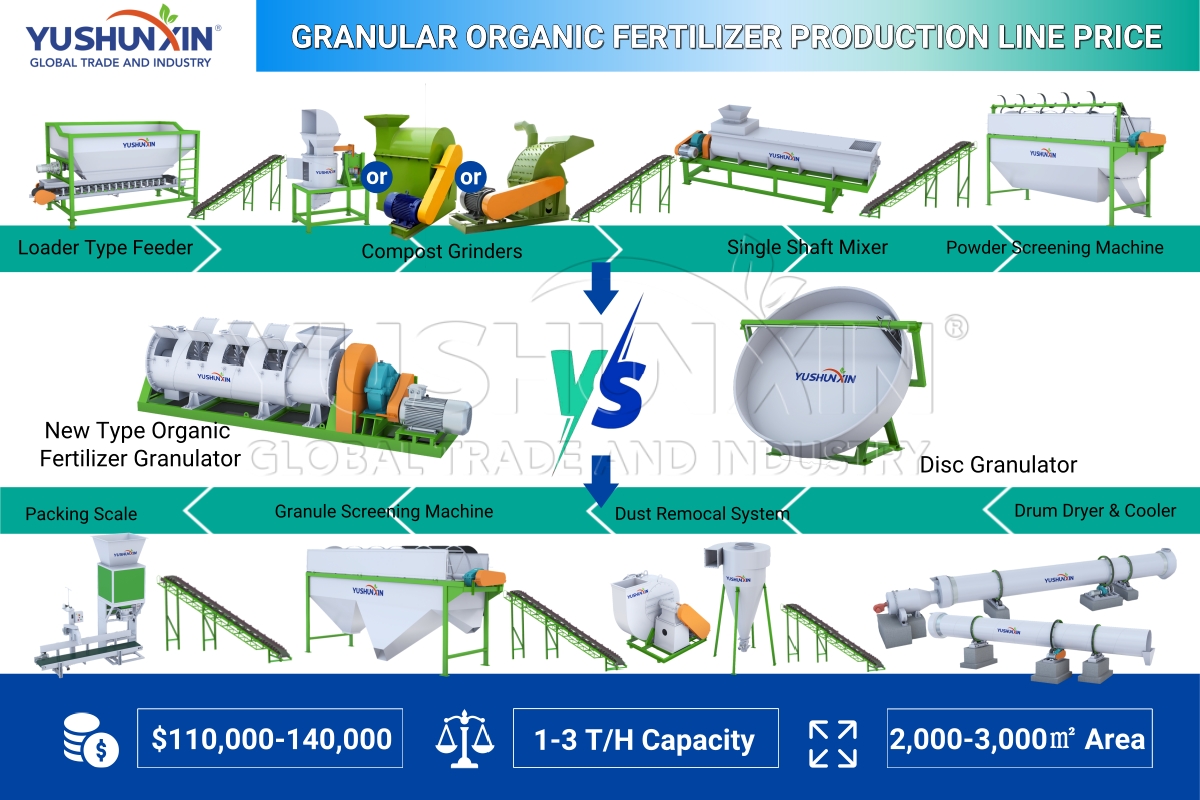

$110,000-140,000 USD Organic Fertilizer Granulation Production Project

Firstly, for small organic fertilizer factories with the annual output of 5,000 tons, we recommend selecting the basic fertilizer proposal – a 1-3 t/h granular organic fertilizer production line. Besides, you need to prepare about 110,000-140,000 USD of investment money. In general, this fertilizer granulation line occupies approximately 2,000-3,000㎡ land, of which the fermentation area accounts for about 200-300 ㎡. So you can buy hydraulic crawler type compost turner to automatically adjust the balance and lift as well as reduce vibration wear. Furthermore, there are 2 cost-effective types of organic fertilizer granulators for customer’s 1-3 t/h fertilizer production needs – new type organic fertilizer granulator or pan pelletizer. Then, such wet granulation machines need a drum dryer and cooler. If you want to reduce equipment cost, you can buy this flat die type pelletizer to make 3-10mm columnar pellets without drying and cooling.

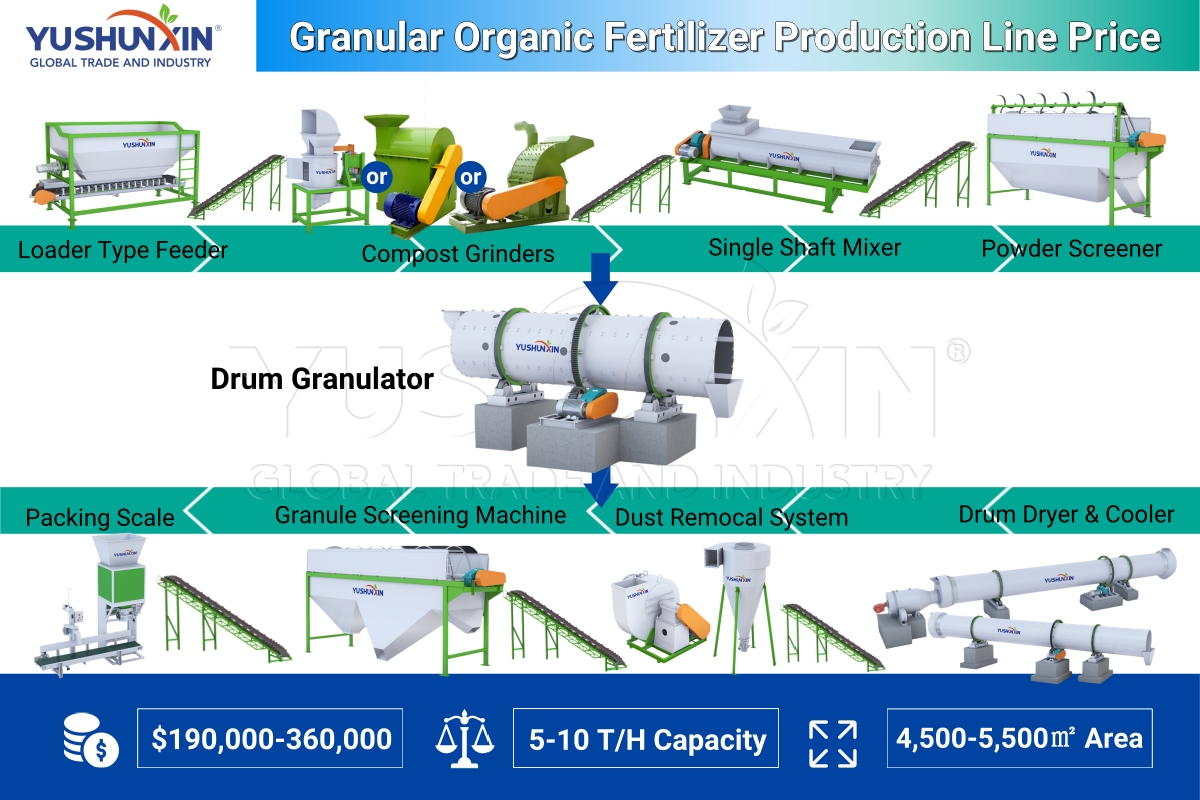

$190,000-360,000 USD Organic Fertilizer Pellet Production Plan

Secondly, medium scale fertilizer plants can produce the annual capacity of 10,000-30,000 tons. So you can try a 5-10 t/h organic fertilizer granulation project. Also, your budget is enough within $190,000-360,000. Furthermore, such a 5-10 t/h granular organic fertilizer production workshop needs 3,000-4,500 square meters land. In this workshop, the composting site requires approximately 500-1,000 ㎡ of space. As a result, you’d better purchase groove type compost machine for high-effective fermentation of organic materials! What’s more, we suggest selecting rotary drum churning granulator or medium model drum pelletizer for commercial organic fertilizer pellet making. Thereby, you may also require crusher, mixer, dryer, cooler, dust collector, screener, packing machines, etc.

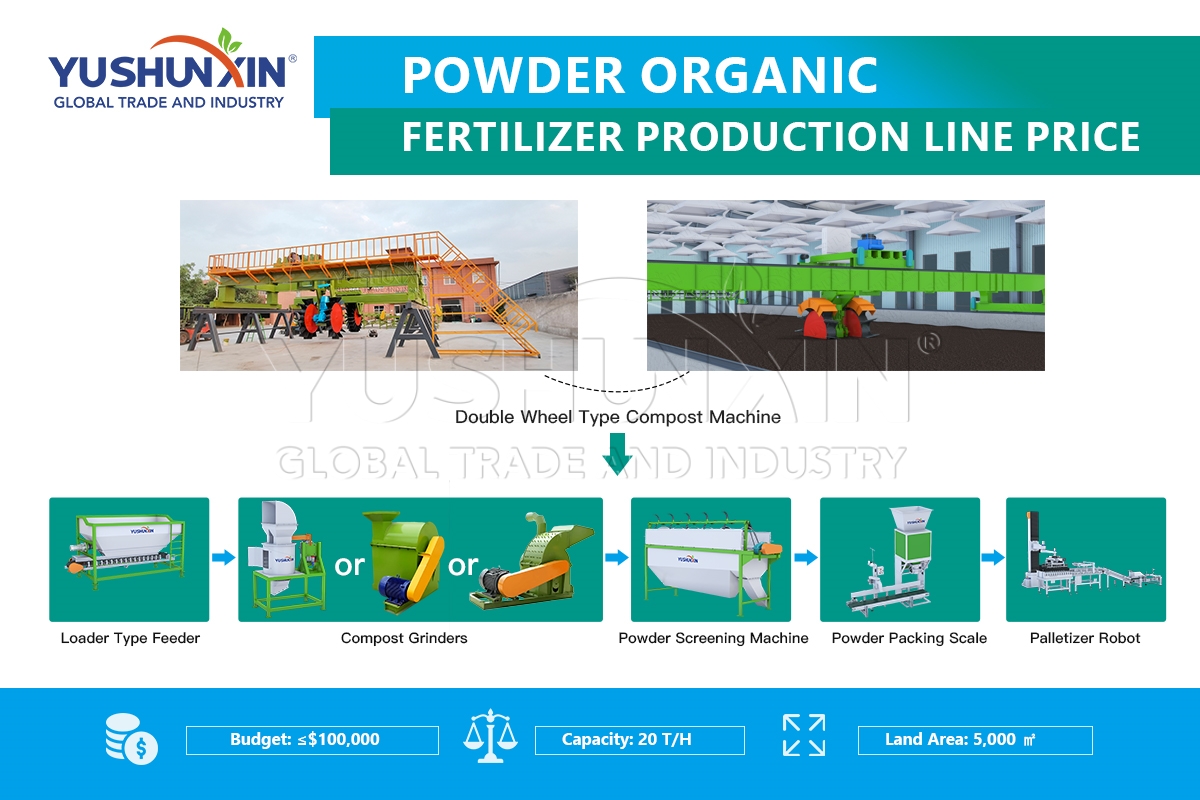

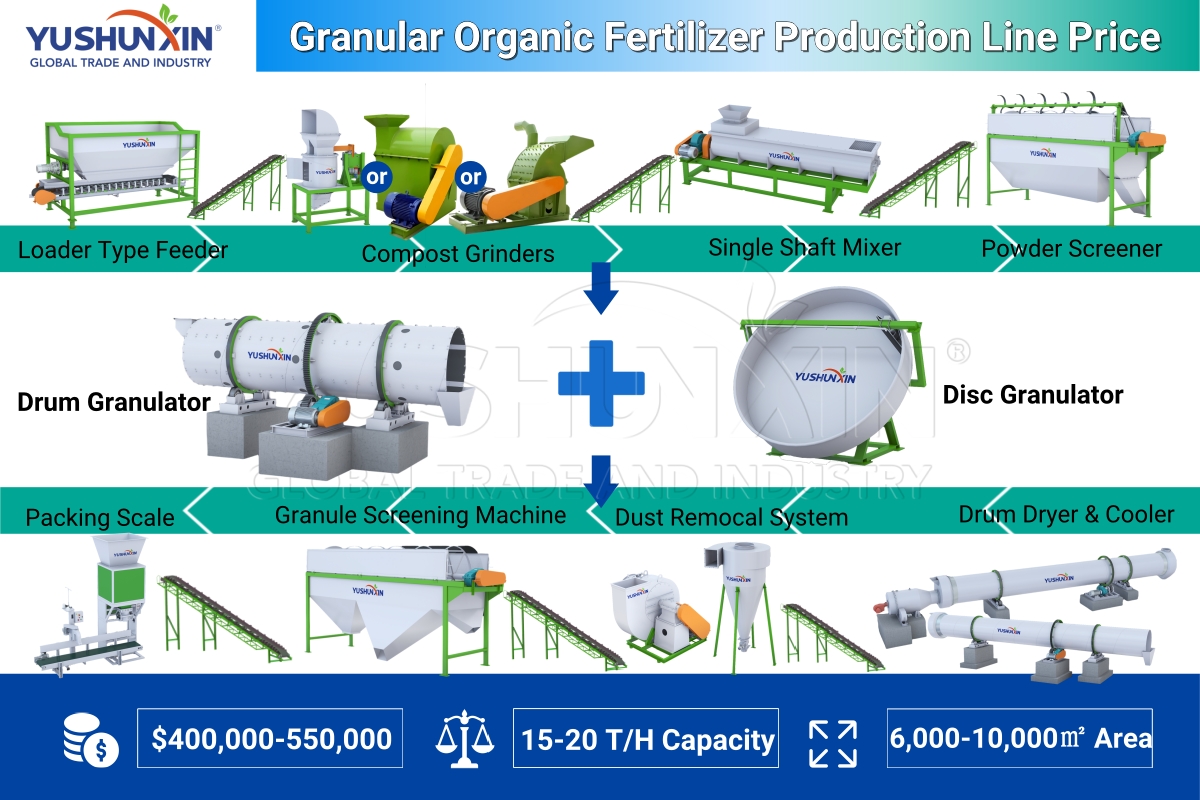

$400,000-550,000 USD Granular Organic Fertilizer Making Proposal

Thirdly, if your budget is about 400,000-550,000 dollars, it’s enough for you to establish a large organic fertilizer pellet machine factory. In addition, such a complete granular organic fertilizer manufacturing line will span an area of 6,000-10,000㎡ and has the output of 15-20 tons per hour. And you need 1,500-2,000㎡ area for organic waste fermentation and composting. It’s suitable to use our double wheel type compost turner with the span of 30 meters. Additionally, for 20 t/h organic fertilizer pelletizing needs, we recommend the use of a combination of drum pelletizing machine and disc pelletizer. The former ensures large yield, and the latter improves pellet formation rate. Besides, you ought to buy 2 rotary dryers to meet drying requirements. Certainly, you can select a polishing machine to make rounder granules. Also, a coating machine can make organic fertilizer particles smooth and bright. You can add microbial agents for enhance nutrients, or change organic fertilizer granular color for hot sales.

What Is The Land Cost to Open An Organic Fertilizer Factory?

To begin with, the most important thing to open an organic fertilizer processing plant is to find suitable land. Actually, you need to keep organic fertilizer plants far away from residential areas, at least 2 kilometers away. Also, it can be close to farms or agricultural production areas, as well as major highways to reduce transportation costs, facilitating the transportation of raw materials and the sales finished fertilizers. In deed, land rents and purchase prices vary greatly according to region, country, degree of urban development, etc. In general, the average price for land lease is between $5-30 per square meter per year. However, the price of purchasing land is much higher, ranging from $100 to $500 per square meter. Thus, low budget clients can decide to rent land. Also, large manufacturers can invest to buy land locally or build organic fertilizer factories in other countries with low rents like Africa.

4 Parts of Land Construction in Organic Fertilizer Factory

4 Parts of Land Construction in Organic Fertilizer Factory

Estimated Cost of Organic Fertilizer Factory For 1,200-14,000㎡ Land

4 Parts of Land Construction in Organic Fertilizer Factory

Estimated Cost of Organic Fertilizer Factory For 1,200-14,000㎡ Land

Estimated Cost of Organic Fertilizer Factory For 1,200-14,000㎡ Land

With an annual output of 5,000 tons to over 100,000 tons, you need to build an organic fertilizer plant covering an area of 1,200-14,000㎡. In theory, the land budget you need to prepare is as follows.

Get Free Quote Now!