Moinho de pellets de matriz plana

The choicest Granulator — Columnar Organic Fertilizer Flat Die Pellet Mill

Nossa empresa has currently developed granulador de matriz plana, which is one of the main organic fertilizer production equipment. Além disso, we design and upgrade it on the basis of the traditional organic fertilizer granulators, overcoming the problems of organic fertilizer like looseness and difficulty in granulation.

- A máquina tem mecanismo simples e design razoável, e os grânulos são fáceis de secar com baixo teor de água.

- Além do mais, the granular materials processed by this machine have smooth surface, dureza moderada, e pode bem manter os nutrientes internos durante o processamento.

We offer a number of models with various types that are appropriate production equipment for small and medium scale fertilizer manufacturing plants. Compared with traditional devices, the flat die pellet mill has great advantages and is considered to be a more efficient way in fertilizer production.

The flat die pelletizer produces columnar pellets without drying or crushing process, que economiza muita energia. Além disso, it will undoubtedly be the best choice for your organic fertilizer granule production!

Obvious Practical Applications of Flat Die Pellet Mill

Granulador de matriz plana is ideal for coarse fiber granulation such as wood chips, canudo, rice husk, cotton stalk, weeds and other kinds of agricultural waste, as well as domestic garbage, waste plastics, and industrial waste. Além do mais, it is useful for granulation and briquetting of materials with low adhesion rate and difficult to shape, and it can also be applied to low temperature granulation of bio-fertilizer, organic fertilizer and compound fertilizer.

Granulador de matriz plana is mainly used for pellet processing of (biológico) organic fertilizer and breeding industry, and it can also be used as livestock feed. De forma similar, it can be used as biomass fuel for boilers, gasifiers, gas stations, and biomass power plants.

Production Procedure by Flat Die Pellet Mill

- The complete granulation line with granulador de matriz plana includes the following equipment: triturador, Máquina de transmissão, misturador, granulador de matriz plana, secador, mais frio, máquina de triagem, storage bin and máquina de embalagem.

- Granulador de matriz plana‘s function is to granulate from organic fertilizer after composting.

1. Differing from the usual method, it eliminates the drying and crushing process of raw materials before granulation, and makes direct batching for processing columnar granules.

2. After the granules form, you can omit the drying and cooling steps, or choose to carry on the finish machining.

- The simplest process flow: conveying → compression molding → storing → packing.

Observação:

- Raw materials like livestock manure with high water content need to be dried before granulation to reduce the moisture.

- Composted materials generally do not need to be finely crushed, while wood chips with suitable moisture can be directly granulated.

- To avoid damage to the roller surface, raw materials with large volume or density must be crushed in advance.

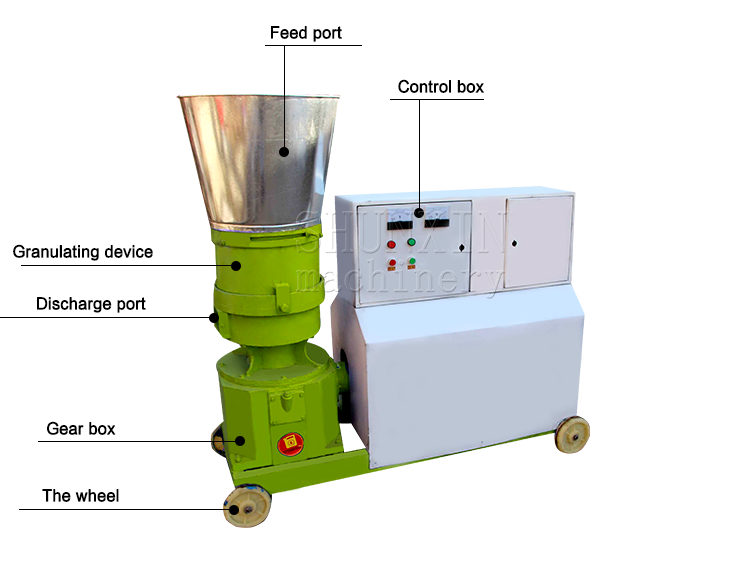

Structure Overview

A principal estrutura de flat die pellet mill consiste em sistema de alimentação e descarga, sistema de granulação, sistema de transmissão e sistema de controle.

Entre eles, the flat die e rolos de extrusão são os principais componentes dos granuladores, whose service life and working condition will directly affect the granulating effect, service life and production efficiency of the entire devices.

How Does A Flat Die Pellet Mill Work?

- Primeiramente, the flat die granulator is based on the mechanical circular motion and powered by an electric motor.

- Under the action of friction, the extrusion rollers rotate themselves and the temperature increases between them and materials, which the high temperature causes the material to melt.

- When working, the flat die granulator uses extrusion rollers and molds to extrude materials with the shape of strips through the small holes of molds.

- Finalmente, while discharging from the outlet, the cutting knives cut these strips to a certain length for finished products.

Why Is The Flat Die Granulator Popular In The Market?

Pellet Mill Flat Die Specifications

|

Modelo |

Capacidade (t/h) | Poder (KW) | Pellet Diameter (mm) |

| SXPM-400 |

1-1.5 |

30 |

2-10 |

|

SXPM-500 |

1.5-2 |

37 |

|

|

SXPM-600 |

2-2.5 |

45 |

Obtenha cotação grátis agora!